Suzuki GSX-R 1000 Service Manual: Special tools and equipment

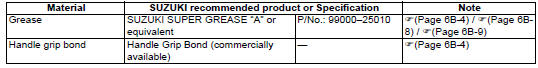

Recommended service material

| Note required service material is also described in the following. “Handlebar components” “steering components” “steering damper construction” |

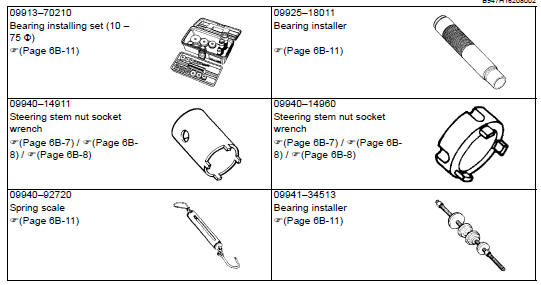

Special tool

Specifications

Specifications

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Handlebar components” “steering components” “steering

damper c ...

Other materials:

Special tools and equipment

Recommended service material

Note

required service material is also described in the following.

“Drive chain related components”

Special tool

...

Warning / caution / note

Please read this manual and follow its instructions

carefully. To emphasize special information, the symbol

and the words warning, caution and note have

special meanings. Pay special attention to the messages

highlighted by these signal words.

Indicates a

potential hazard that could ...

Front turn signal light bulb replacement

Caution

when you touch the bulb with your bare

hands, clean the bulb with a cloth moistened

with alcohol or soap water to prevent

premature bulb failure.

Remove the turn signal light assembly.

Remove the socket (1) by turning it

counterclockwise.

Repla ...