Suzuki GSX-R 1000 Service Manual: Excva adjustment

Inspect the excva operation and adjust it if necessary in the following steps:

Step 1

- Set the excva to the adjustment position. Refer to “excv cable removal and installation” (page 1k- 6).

Step 2

- Turn the ignition switch off.

- Turn the mode select switch off.

- Turn the ignition switch on and check the operation

of excva.

(Excva operation order: full close → full open → approx. 60% Open)

- Turn the mode select switch on. If dtc “c46” is not indicated on the lcd display, the adjustment is correctly completed. If “c46” is indicated, repeat the procedures from step 3 to step 4.

Step 3

- Turn the ignition switch off.

- Set up the sds tools. Refer to “self-diagnostic procedures” in section 1a .

- Turn the ignition switch on.

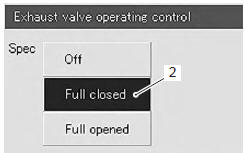

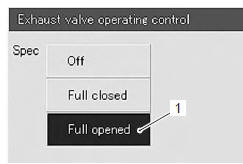

- Click “exhaust valve operating control” (1).

- Click “full closed” (2).

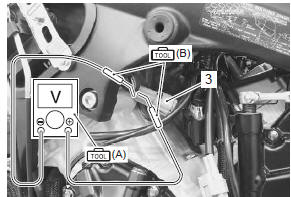

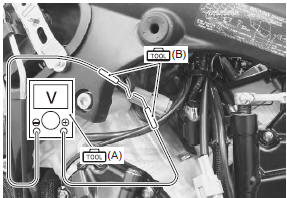

- Insert the needle pointed probes into the back side of the excva coupler (3). ((+) Y – (–) w)

- Measure the excva position sensor output voltage at excv fully closed position.

Special tool

(a): 09900–25008 (multi circuit

(a): 09900–25008 (multi circuit

tester set)

(b): 09900–25009 (needle-point

(b): 09900–25009 (needle-point

probe set)

Tester knob indication

voltage ( )

)

Excva position sensor output voltage excv is fully closed: 0.45 ≤ Output voltage ≤ 1.4 V ((+) y - (-) W)

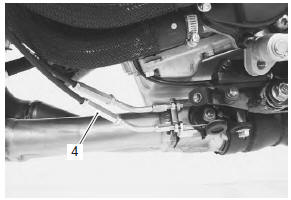

- If the measured voltage is less than specification, adjust the no. 1 Cable adjuster (4) as follows:

- set the excva to the adjustment position. Refer to “excv cable removal and installation” .

| Caution adjusting the no. 1 Cable with the excv fully closed can damage the excva. Be sure to adjust the no. 1 Cable with the excv set in the adjustment position. |

- Turn the no. 1 Cable adjuster (4) in or out to set the output voltage within the specified value.

| Note if c46 code is indicated after adjusting the voltage, increase the voltage to 0.9 V. |

Step 4

- Measure the excva position sensor output voltage at excv fully opened position.

Special tool

(a): 09900–25008 (multi circuit

(a): 09900–25008 (multi circuit

tester set)

(b): 09900–25009 (needle-point

(b): 09900–25009 (needle-point

probe set)

Excva position sensor out put voltage excv is fully opened: 3.6 ≤ Output voltage ≤ 4.55 V ((+) y - (-) W)

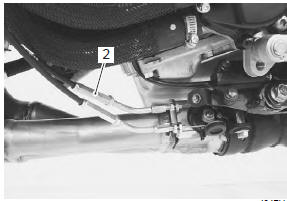

- If the measured voltage is more than specification, adjust the no. 2 Cable adjuster (2) as follows:

- set the excva to the adjustment position. Refer to “excv cable removal and installation” .

| Caution adjusting the no. 2 Cable with the excv fully opened can damage the excva. Be sure to adjust the no. 2 Cable with the excv set in adjustment position. |

- Turn out the no. 2 Cable adjuster (2) in or out to set the output voltage within the specified value.

- After adjusting the excv cables, perform step 2 to confirm dtc “46” is not indicated.

Excva pulley inspection

Excva pulley inspection

Inspect the excva pulley in the following procedures:

remove the excva pulley. Refer to “excv cable removal and installation”

.

Visually inspect the excva pulley for wear and

da ...

Muffler / muffler chamber / exhaust pipe

removal and installation

Muffler / muffler chamber / exhaust pipe

removal and installation

Removal

Loosen the muffler connecting bolts (1).

Remove the mufflers (2) by removing the mounting

bolt and nut (3).

Note

support the muffler to prevent it from falling.

...

Other materials:

Modification

Modification of the motorcycle, or

removal of original equipment

may render the vehicle unsafe or

illegal. Obey all applicable equipment

regulations in your area.

The frame of this motorcycle is

made of an aluminum alloy.

Therefore, never make any modifications

such as drilling or weldin ...

Ignition switch inspection

Inspect the ignition switch in the following procedures:

remove the air cleaner box. Refer to “air cleaner box removal and

installation” in section 1d .

Disconnect the ignition switch lead wire coupler (1).

Inspect the ignition switch for continuity with a tester.

If ...

Specifications

Service data

Wattage

unit: w

Tightening torque specifications

Reference: for the tightening torque of fastener not specified in this

section, refer to “tightening torque list” in section 0c . ...