Suzuki GSX-R 1000 Service Manual: Excva removal and installation

Removal

- Turn the ignition switch off.

- Remove the left side cowling. Refer to “exterior parts removal and installation” in section 9d .

- Connect the special tool (mode select switch) to the dealer mode coupler. Refer to “self-diagnostic procedures” in section 1a .

- After turning the mode select switch on, turn the ignition switch on.

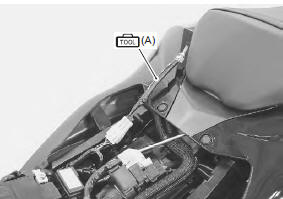

Special tool

(a): 09930–82720 (mode selection

(a): 09930–82720 (mode selection

switch)

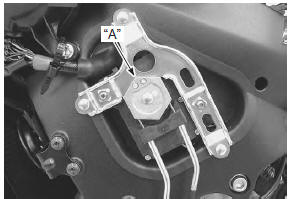

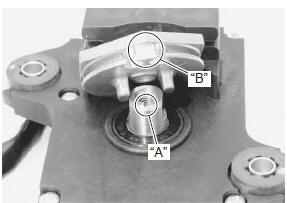

- Check that the cable slots of the excva pulley comes to the middle (adjustment position) “a”.

- Turn the ignition switch off.

| Caution before removing the excva, be sure to set the excva pulley to the adjustment position. |

- Disconnect the excva coupler (1).

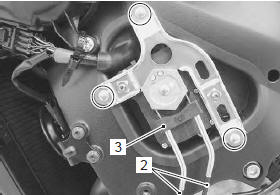

- Remove the excv cables (2). Refer to “excv cable removal and installation” .

- Remove the excva (3) with the bracket.

- Remove the bracket from the excva

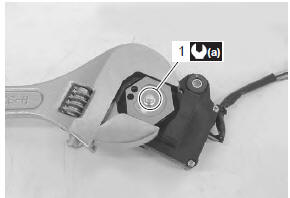

- Hold the pulley with an adjustable wrench, and loosen the pulley mounting bolt (4).

Caution

|

- Remove the pulley from the excva body.

Installation

Install the excva in the reverse order of removal. Pay attention to the following points:

- install the excva pulley to the shaft.

| Note align the shaft’s line “a” and cable slots “b”. |

- Hold the pulley with an adjustable wrench, and then tighten the pulley mounting bolt (1) to the specified torque.

Tightening torque excva pulley mounting bolt (a): 5 n·m (0.5 Kgfm, 3.5 Lbf-ft)

| Caution when loosening or tightening the pulley bolt, be sure to fix the pulley with an adjustable wrench, or excva may get damaged. |

- Install the excv cables. Refer to “excv cable removal and installation” .

- Adjust the excva. Refer to “excva adjustment” .

Excva inspection

Refer to “dtc “c46” (p1657-h/l or p1658): excv actuator circuit malfunction” in section 1a (page 1a- 109).

Excv cable removal and installation

Excv cable removal and installation

Removal

Turn the ignition switch off.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Remove the left side cowling. Refer ...

Excva pulley inspection

Excva pulley inspection

Inspect the excva pulley in the following procedures:

remove the excva pulley. Refer to “excv cable removal and installation”

.

Visually inspect the excva pulley for wear and

da ...

Other materials:

Engine coolant temperature indicator light inspection

Inspect the engine coolant temperature meter and indicator light (led) in the

following procedures:

remove the left side cowling. Refer to “exterior parts removal and

installation” in section 9d .

Disconnect the ect sensor coupler (1).

Connect a variable resistor (2) ...

Clutch cable play inspection and adjustment

Inspect clutch cable play

every 6 000 km (4 000 miles, 12 months)

Inspect and adjust the clutch cable play “a” as follows.

Clutch cable play “a”

10 – 15 mm (0.4 – 0.6 In)

Lift and support the fuel tank. Refer to “fuel tank

removal and installation” in section 1g (page 1g-

9).

...

Front brake master cylinder assembly removal and installation

Removal

Drain brake fluid. Refer to “brake fluid replacement” .

Disconnect the front brake light switch coupler (1).

Place a rag underneath the brake hose union bolt (2)

on the master cylinder to catch any spilt brake fluid.

Remove the brake hose union bolt (2).

...