Suzuki GSX-R 1000 Service Manual: Special tools and equip

Recommended service material

Special tool

Specifications

Specifications

Service data

Fi sensors

Tightening torque specifications

Reference: for the tightening torque of fastener not specified in this

section, refer to “tightening torque list” in section 0c . ...

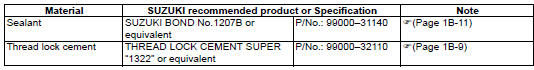

Other materials:

Rear brake light switch inspection

Inspect the rear brake light switch in the following

procedures:

lift and support the fuel tank. Refer to “fuel tank

removal and installation” in section 1g (page 1g-

9).

Disconnect the rear brake light switch lead wire

coupler (1).

Inspect the rear brake light swi ...

Component location

Electrical components location

Ignition switch/immobilizer antenna

Iat sensor

Secondary fuel injector

Primary fuel injector

Iap sensor

Evap system purge control solenoid valve

Fuel pump relay

Turn signal/side-stand relay

Cooling fan relay

Ect ...

Conrod and crankshaft inspection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Conrod small end I.D.

Measure the conrod small end inside diameter using the

small bore gauge.

If the conrod small end inside diameter exceeds the

service limit, replace the conrod.

Special ...