Suzuki GSX-R 1000 Service Manual: Throttle body removal and installation

Removal

- Remove the side cowlings. Refer to “exterior parts removal and installation” in section 9d (page 9d- 6).

- Remove the air cleaner box. Refer to “air cleaner box removal and installation” .

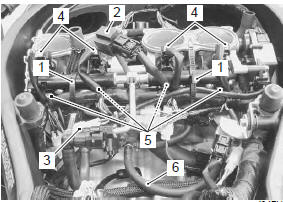

- Remove the clamps (1).

- Disconnect the iap sensor (2) from the vacuum hose.

- Disconnect the stva lead wire coupler (3).

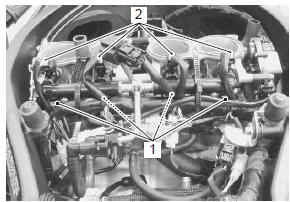

- Disconnect secondary fuel injector couplers (4) and primary fuel injector couplers (5).

- Disconnect the purge hose (6) from the evap system purge control solenoid valve. (E-33 only)

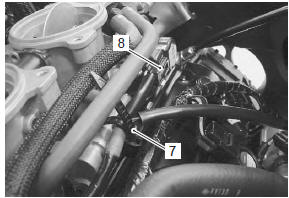

- Remove the clamp (7).

- Disconnect the isc valve coupler (8).

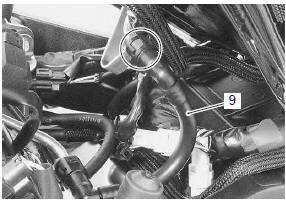

- Place a rag under the fuel feed hose (9) and disconnect the fuel feed hose from the fuel pump.

For e-33 For e-33

models, drain fuel from the fuel tank before disconnecting the fuel feed hose to prevent fuel leakage. |

- Loosen the throttle body clamp screws, left and right.

- Lift up the throttle body from the intake pipes.

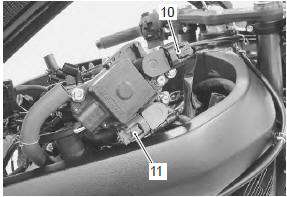

- Disconnect the stp sensor coupler (10) and tp sensor coupler (11).

- Disconnect the throttle cables.

| Caution after disconnecting the throttle cables, do not snap the throttle valve from full open to full close. It may cause damage to the throttle valve and throttle body. |

- Remove the throttle body.

Installation

Installation is in the reverse order of removal. Pay attention to the following points:

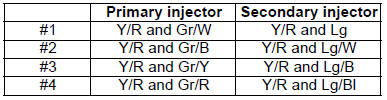

- connect the primary injector couplers (1) and secondary injector couplers (2) to the respective fuel injectors. Make sure that each coupler is installed in the correct position. The color on each lead wire refers to the appropriate fuel injector.

- Connect the throttle cable no. 1 (3) And throttle cable no. 2 (4) To the throttle cable drum.

|

- Loosen each throttle cable lock-nut.

- Turn in each throttle cable adjuster fully and locate each outer cable so that the clearance “a” is 0 – 1 mm (0 – 0.04 In).

- Tighten each lock-nut.

Tightening torque throttle cable lock-nut: 4.5 N·m (0.45 Kgf-m, 3.0 Lbf-ft)

- Adjust the throttle cable play. Refer to “throttle cable play inspection and adjustment” in section 0b .

- Reset the isc valve and tp sensor learned values.

Refer to “isc valve reset” and “tp reset” .

Throttle body construction

Throttle body construction

Intake pipe

Evap system purge control solenoid valve

(e-33 only)

Evap canister (e-33 only)

Iat sensor

Isc valve hose

Ho2 sensor

Face

the clamp end ...

Throttle body disassembly and assembly

Throttle body disassembly and assembly

Refer to “throttle body removal and installation” .

Disassembly

Caution

identify the position of each removed part.

Organize the parts in their respective groups

so that they can be ...

Other materials:

Clutch control system components

Push rod

Clutch release camshaft

Clutch release arm

Clutch cable

1 N·m (0.1 Kgf-m, 0.7

Lbf-ft)

6 N·m

(0.6 Kgf-m, 4.5 Lbf-ft)

10 N·m

(1.0 Kgf-m, 0.7 Lbf-ft)

Apply grease

Do not reuse.

...

Rear brake components

Rear brake caliper

Piston seal

Dust seal

Piston

Rear caliper bracket

Rear brake pad set

Rear brake disc

Brake pad spring

6

N·m (0.6 Kgf-m, 4.5 Lbf-ft)

27 N·m

(2.7 Kgf-m, 19.5 Lbf-ft)

12 N·m

(1.2 Kgf-m, 8.5 Lbf-ft)

17 N·m ...

Rear view mirror construction

Body cowling

Cowling brace

Cushion

Turn signal lead wire

Turn signal lead

wire coupler

: locate the turn signal lead wire coupler (5) between the

mirror cover (6) and mirror body (7).

Mirror cover

Mirror body

10 N·m (1.0 Kgf-m, 7.0 L ...