Suzuki GSX-R 1000 Service Manual: DTC “c15” (p0115-h/l): ect sensor circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

||

| C15 | Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < 4.85 V |

|

|

| P0115 | H | Sensor voltage is higher than specified value. | |

| L | Sensor voltage is lower than specified value. | ||

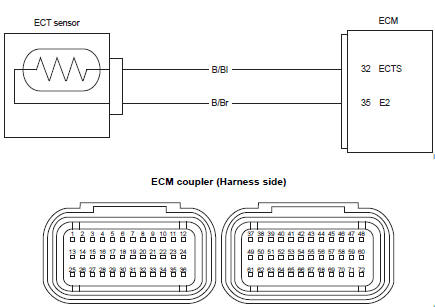

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

C15 (use of mode select switch)

|

Step |

Action |

Yes |

No |

|

1 |

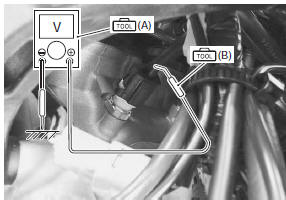

Special tool Tester knob indication

voltage ( Ect sensor input voltage 4.5 – 5.5 V ((+) terminal: b/bl – (–) terminal: ground, (+) terminal: b/bl – (–) terminal: b/br)

Is the voltage ok? |

Go to step 2. |

|

P0115-h (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

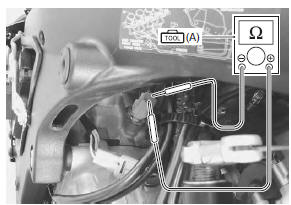

Special tool Tester knob indication

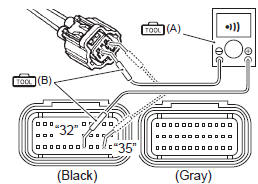

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | B/bl or b/br wire open. |

P0115-l (use of sds)

|

Step |

Action |

Yes |

No |

|

|

1 |

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

voltage ( Ect sensor output voltage 0.15 – 4.85 V ((+) terminal: b/bl – (–) terminal: ground)

Are the continuity and voltage ok? |

Go to step 2. |

|

|

|

2 |

Special tool Tester knob indication resistance (Ω) Ect sensor resistance approx. 2.45 KΩ at 20 °c (68 °f) (terminal – terminal)

Is the resistance ok? |

|

Replace the ect

sensor with a new one. Refer to “ect sensor removal and installation” in section 1c . |

DTC “c14” (p0120-h/l): tp sensor circuit

malfunction

DTC “c14” (p0120-h/l): tp sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C14

Output voltage is not within the following

range.

Difference between actual throttle op ...

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C21

Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < ...

Other materials:

Pair system hose routing diagram

Pair control solenoid valve

Pair reed valve

White marking (hidden side)

Yellow marking

Blue marking

Red marking

Face the

clamp end to the top.

Make sure

the clamp is not contacted to the frame or air cleaner box.

90°

45°

15°

...

Fuel tank removal and installation

Removal

Keep away from fire or spark.

Spilled gasoline should be wiped off

immediately.

Work in a well-ventilated area.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Take ...

Starter relay removal and installation

Removal

Turn the ignition switch off.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the battery (–) lead wire (1) from the

battery.

Remove the starter relay cover (2) and disconnect

the starter rel ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)