Suzuki GSX-R 1000 Service Manual: DTC “c14” (p0120-h/l): tp sensor circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

||

| C14 | Output voltage is not within the following

range. Difference between actual throttle opening and opening calculated by ecm is larger than specified value. 0.2 V ≤ Sensor voltage < 4.8 V |

|

|

| P0120 | H | Sensor voltage is higher than specified value. |

|

| L | Sensor voltage is lower than specified value. | ||

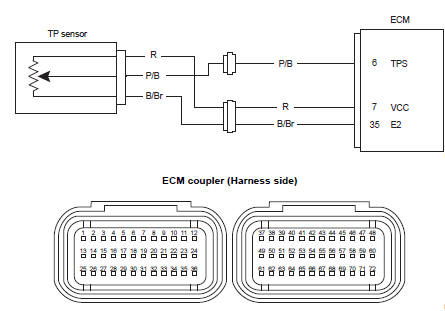

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

C14 (use of mode select switch)

|

Step |

Action |

Yes |

No |

| 1 |

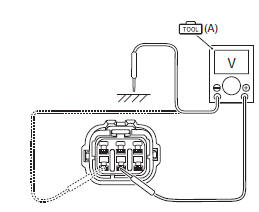

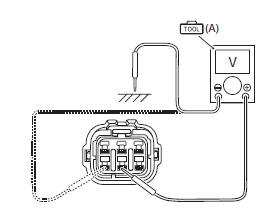

Special tool

Tester knob indication

voltage ( Tp sensor input voltage 4.5 – 5.5 V ((+) terminal: r – (–) terminal: ground, (+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. |

|

P0120-h (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

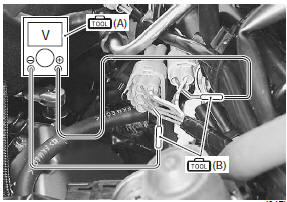

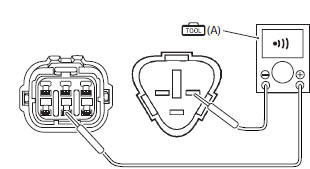

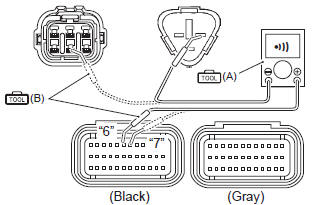

Special tool Tester knob indication

continuity (

Special tool Tester knob indication continuity test ( ) Ecm couplers (harness side)

Is the continuity ok? |

Go to step 3. | P/b wire shorted to vcc, or b/br wire open |

P0120-l (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

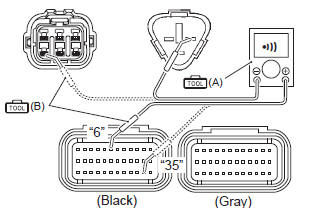

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | R or p/b wire open, or y/w wire shorted to ground. |

|

2 |

Special tool Tester knob indication

voltage ( Tp sensor input voltage 4.5 – 5.5 V ((+) terminal: r – (–) terminal: ground, (+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. | Open or short circuit in the r or b/br wire. |

|

3 |

Special tool Tester knob indication

voltage ( Tp sensor output voltage throttle valve is closed: approx. 1.1 V throttle valve is opened: approx. 4.4 V ((+) terminal: p/b – (–) terminal: b/br)

Is the voltage ok? |

|

If check result is not

satisfactory, replace tp

sensor with a new one. Refer to “throttle body disassembly and assembly” in section 1d . |

DTC “c13” (p0105-h/l): iap sensor circuit

malfunction

DTC “c13” (p0105-h/l): iap sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C13

Iap sensor voltage is not within the

following range.

0.5 V ≤ Sensor voltage &l ...

DTC “c15” (p0115-h/l): ect sensor circuit

malfunction

DTC “c15” (p0115-h/l): ect sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C15

Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < ...

Other materials:

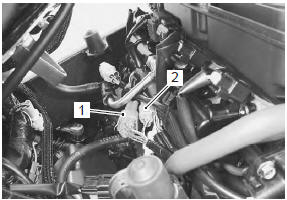

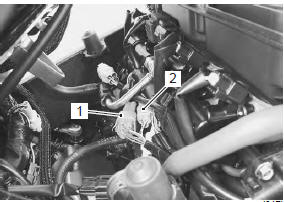

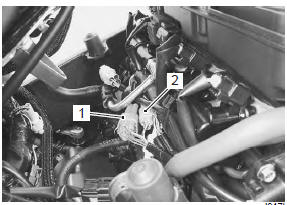

Ap sensor removal and installation

Removal

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the starter relay (1) from the holder.

Disconnect the coupler (2) and remove the ap

sensor (3).

Installation

Install the ap sensor in the rever ...

Conclusion

Traffic, road and weather conditions

vary. Other motorists'

actions are unpredictable. Your

motorcycle's condition can

change. These factors can best

be dealt with by giving every ride

your full attention.

Circumstances beyond your control

could lead to an accident. You

need to prepare fo ...

Fail-safe function table

Fi system is provided with fail-safe function to allow the engine to start

and the motorcycle to run in a minimum

performance necessary even under malfunction condition.

The engine can start and can run even if the signal in the table is not

received from each sensor. But, the engine

...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)

)

)