Suzuki GSX-R 1000 Service Manual: Wiring harness routing diagram

Clamp Clamp

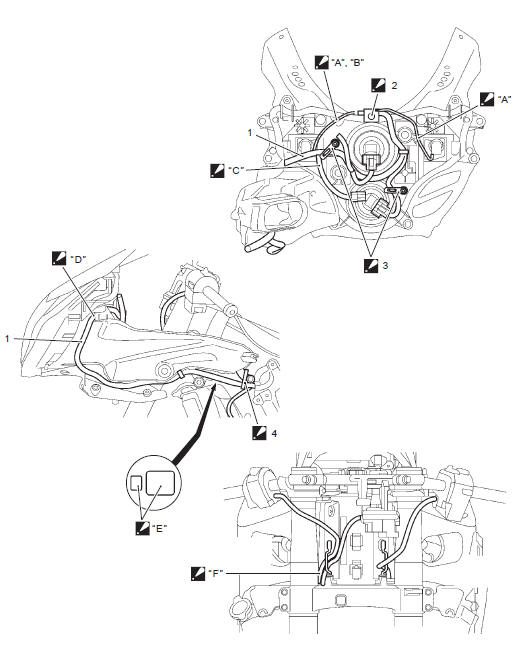

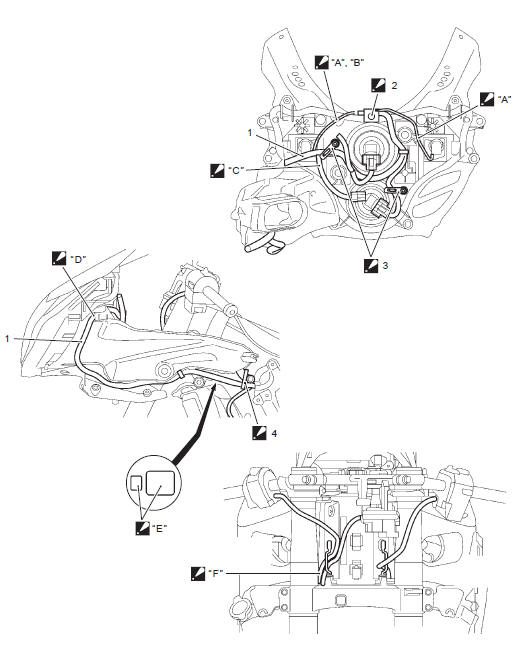

: pass the side-stand switch lead wire left side of the water bypass

hose and clamp them in this range. Cut off the excess tip

of the clamp. Clamp Clamp

: bind the lead wires at the blue taping point and face the clamp

end to the engine side.- Iat sensor

- Isc valve

Clamp Clamp

: bind the lead wires with throttle body at blue taping point and

face the clamp end forward.- White coupler (for ignition coil #1)

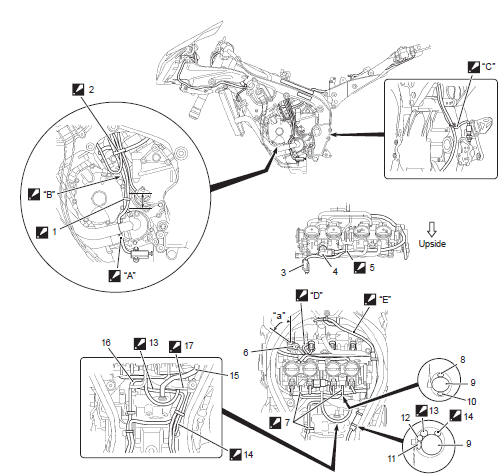

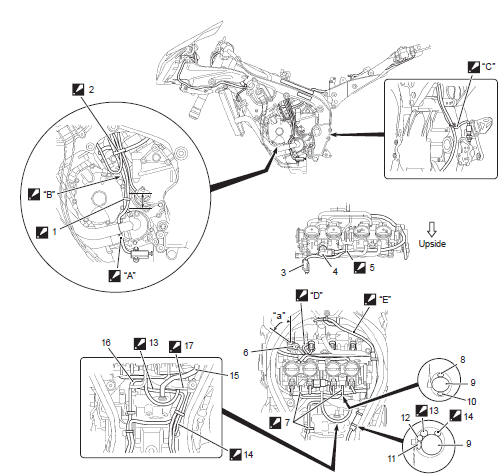

Clamp: Clamp:

face the clamp end upward.- Stva lead wire

- Wiring harness

- Isc valve lead wire

- Regulator/rectifier lead wire

- Evap system purge control solenoid valve lead wire (e-33 only)

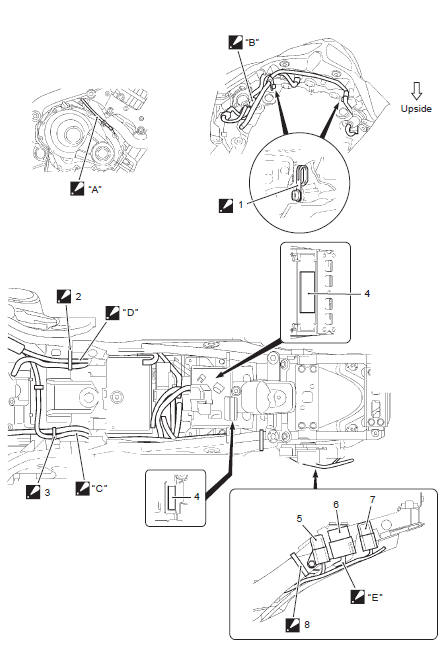

Battery negative Battery negative

lead wire

: pass the battery negative lead wire in front of the pcv hose. (For

e-33, pass

the lead wire below the evap solenoid hoses, and between the evap

solenoid

lead wire and wiring harness.) Rear brake light Rear brake light

switch lead wire

: pass the rear brake light switch lead wire below the wiring

harness and battery

negative lead wire at the frame bridge part, then above the wiring

harness at

the fuel tank rail part. (For e-33, pass the brake light switch lead

wire between

evap solenoid bracket and frame.)- Crankcase breather (pcv) hose

- Starter motor lead wire

Kp sensor lead wire Kp sensor lead wire

: route the ckp sensor lead wire in front of the pcv hose and above

the

battery negative lead wire. Pass Pass

the side-stand switch lead wire between the water hoses. Plate the Plate the

joint coupler to the engine side and pass the side-stand switch lead

wire and speed sensor lead wire left side of the water by-pass hose. Pass the Pass the

rear brake light switch lead wire between the frame and drain hose,

and under the clamp. Pass the Pass the

cmp sensor lead wire between ignition coil #1 and #2. Pass the Pass the

wiring harness above the air cleaner duct.- 60 ± 5°

|

Refer to “wire color symbols” in section 0a .

For e-02, 19, 24, 51

For e-03, 28

For e-14, 33

...

Service data

Electrical

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Wiring harness routing diagram”

Reference: ...

Other materials:

Ecm / various sensors

Since each component is a high-precision part, great

care should be taken not to apply any severe impacts

during removal and installation.

Be careful not to touch the electrical terminals of the

electronic parts (ecm, etc.). The static electricity from

your body may damage them. ...

Specifications

Specifications

Note

these specifications are subject to change without notice.

Dimensions and dry mass

Engine

Drive train

Chassis

Electrical

Capacities

...

Light bulb replacement

The wattage rating of each bulb is

shown in the following chart.

When replacing a burned-out

bulb, always use the same wattage

rating according to the following

chart.

Caution

Using a light bulb with the

wrong wattage rating can

cause electrical system damage

or shorte ...

Wiring diagram

Wiring diagram Specifications

Specifications

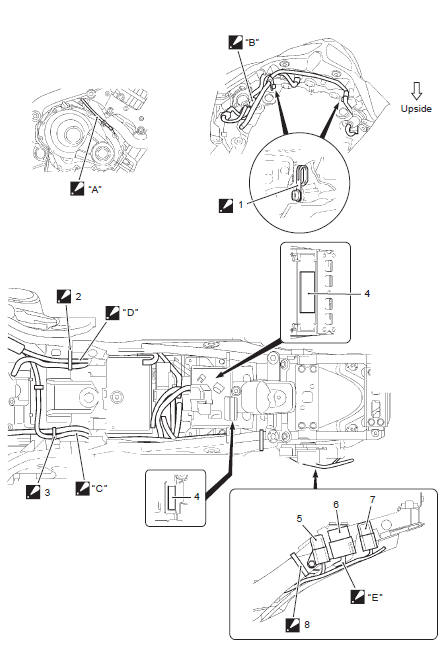

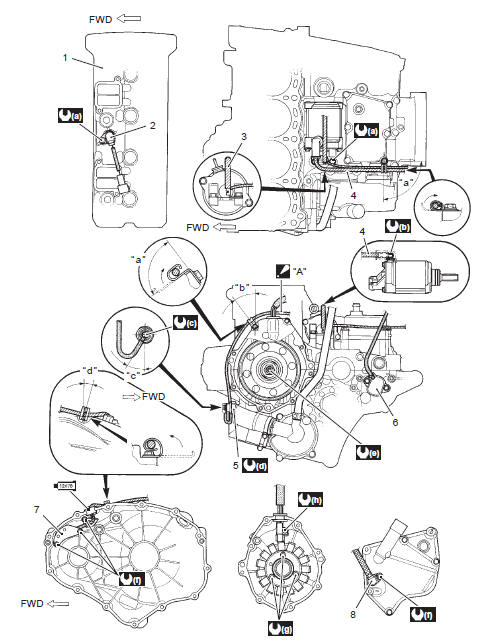

Tapping clamp

Tapping clamp

Steel clamp

Steel clamp

Clamp:

Clamp:

Take

Take

Pass the

Pass the

Route the

Route the

Pass the

Pass the

Place the

Place the

Pass the

Pass the

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp:

Clamp:

Battery negative

Battery negative

Rear brake light

Rear brake light

Kp sensor lead wire

Kp sensor lead wire

Pass

Pass

Plate the

Plate the

Pass the

Pass the

Pass the

Pass the

Pass the

Pass the

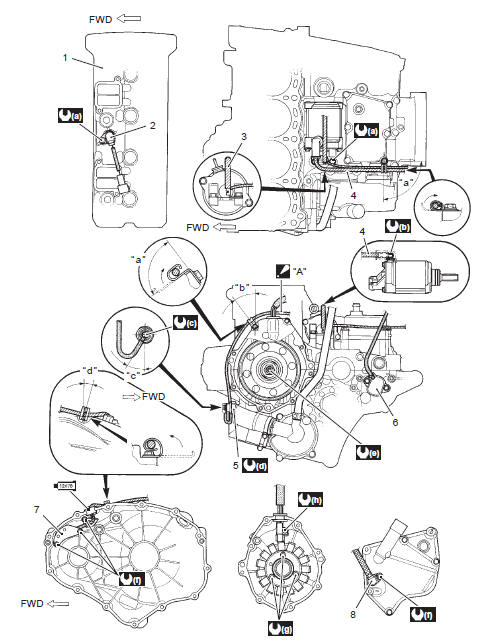

Steel clamp

Steel clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Clamp

Be

Be

Put the

Put the

Do not

Do not

Bring the

Bring the

Put the

Put the

Pass

Pass

10

10

4 N·m (0.4

4 N·m (0.4

1.5 N·m

1.5 N·m

14 N·m

14 N·m

145 N·m

145 N·m

6.5 N·m

6.5 N·m

11 N·m

11 N·m

5.5 N·m

5.5 N·m

Apply bond.

Apply bond.