Suzuki GSX-R 1000 Service Manual: Sds check

Using sds, sample the data at the time of new and periodic vehicle inspections.

After saving the sampled data in the computer, file them by model and by user.

The periodically filed data help improve the accuracy of troubleshooting since they can indicate the condition of vehicle functions that has changed with time.

For example, when a vehicle is brought in for service but the troubleshooting of a failure is not easy, comparing the current data value to past filed data value at time of normal condition can allow the specific engine failure to be determined.

Also, in the case of a customer vehicle which is not periodically brought in for service with no past data value having been saved, if the data value of a good vehicle condition have been already saved as a master (std), comparison between the same models helps to facilitate the troubleshooting.

- Remove the front seat. Refer to “exterior parts removal and installation” in section 9d .

- Set up the sds tool. (Refer to the sds operation manual for further details.)

Special tool

: 09904–41010 (suzuki diagnostic

: 09904–41010 (suzuki diagnostic

system set)

: 99565–01010–020 (cd-rom ver.20)

: 99565–01010–020 (cd-rom ver.20)

Note

|

Sample

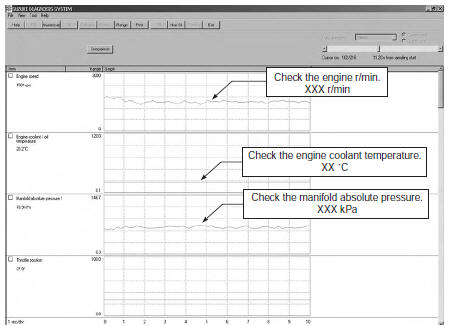

Data sampled from cold starting through warm-up

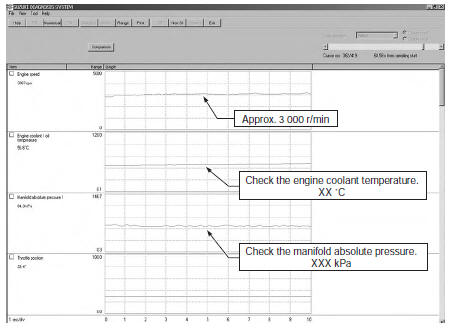

Data at 3 000 r/min under no load

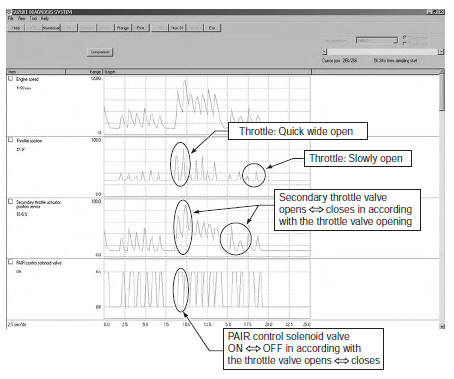

Data at the time of racing

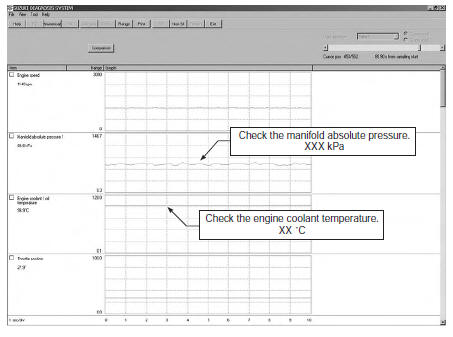

Data of intake negative pressure during idling (100 °c)

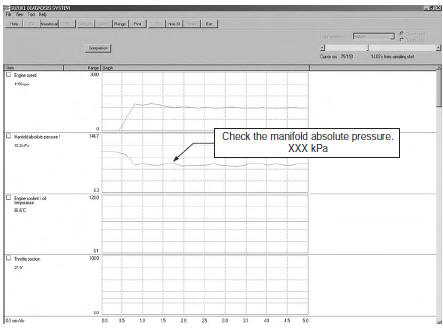

Data of manifold absolute pressure operation at the time of starting

Example of trouble

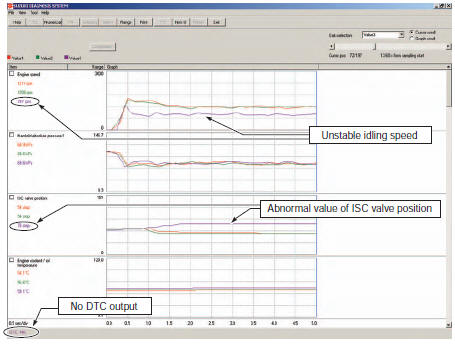

Three data; value 3 (current data 3), value 1 (past data 1) and value 2 (past data 2); can be made in comparison by showing them in the graph. Read the change of value by comparing the current data to the past data that have been saved under the same condition, then you may determine how changes have occurred with the passing of time and identify what problem is currently occurring.

| Note with dtc not output, if the engine idling speed and isc valve stepping position are found to be abnormal than the data saved previously, the possible cause may probably lie in the hardware side such as isc valve air inlet hose crumple, bend, etc. |

Show data when trouble (displaying data at

the time of DTC)

Show data when trouble (displaying data at

the time of DTC)

Use of sds

Ecm stores the engine and driving conditions (in the form of data as shown in

the figure) at the moment of the

detection of a malfunction in its memory. This data is called “show data w ...

DTC table

DTC table

In the lcd (display) panel, the malfunction code is indicated from small code

to large code.

*1 To get the proper signal from the throttle position sensor, the sensor basic

position is ...

Other materials:

Drive chain related components

Drive chain

Engine sprocket

Rear sprocket

Dust seal

Bearing

Retainer

Sprocket mounting drum

Wheel damper

145 N·m (14.5 Kgf-m,

105.0 Lbf-ft)

60 N·m

(6.0 Kgf-m, 43.0 Lbf-ft)

Apply grease

Apply thread lock to

thread p ...

Rear suspension assembly construction

Rear shock absorber mounting bolt (upper)

Rear shock absorber mounting nut (lower)

Cushion rod mounting nut (front)

Cushion rod mounting nut (rear)

Cushion lever mounting nut

Swingarm pivot nut

Swingarm pivot boss nut

Swingarm pivot shaft

Swingarm ...

Specifications

Service data

Suspension

unit: mm (in)

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Rear suspension components” “rear suspension assembly

construction”

Reference: for the tightening torque of fastener ...