Suzuki GSX-R 1000 Service Manual: Conrod and crankshaft inspection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Conrod small end I.D.

Measure the conrod small end inside diameter using the small bore gauge.

If the conrod small end inside diameter exceeds the service limit, replace the conrod.

Special tool

(a): 09900–20602 (dial gauge)

(a): 09900–20602 (dial gauge)

(b): 09900–22401 (small bore gauge

(b): 09900–22401 (small bore gauge

(10 – 18

mm))

Conrod small end i.D.

Service limit: 15.040 Mm (0.5921 In)

Conrod big end side clearance

- Check the conrod big end side clearance using the thickness gauge.

Special tool

(a): 09900–20803 (thickness gauge)

(a): 09900–20803 (thickness gauge)

Conrod big end side clearance service limit: 0.30 Mm (0.012 In)

- If the clearance exceeds the limit, remove the conrod and measure the conrod big end width and crank pin width. Refer to “engine bottom side assembly” . If any of the measurements are out of specification, replace the conrod or crankshaft.

Special tool

(b): 09900–20205 (micrometer (0 –

(b): 09900–20205 (micrometer (0 –

25 mm))

(c): 09900–20605 (dial calipers (10

(c): 09900–20605 (dial calipers (10

– 34

mm))

Conrod big end width standard: 19.95 – 20.00 Mm (0.7854 – 0.7874 In)

Crank pin width standard: 20.10 – 20.15 Mm (0.7913 – 0.7933 In)

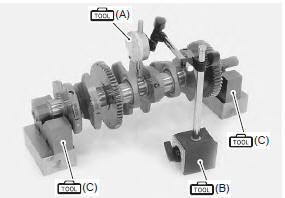

Crankshaft runout

Support the crankshaft using v-blocks as shown, with the two end journals resting on the blocks. Set up the dial gauge as shown, and rotate the crankshaft slowly to read the runout. Replace the crankshaft if the runout exceeds the service limit.

Special tool

(a): 09900–20607 (dial gauge)

(a): 09900–20607 (dial gauge)

(b): 09900–20701 (dial gauge chuck)

(b): 09900–20701 (dial gauge chuck)

(c): 09900–21304 (v blocks)

(c): 09900–21304 (v blocks)

Crankshaft runout service limit: 0.05 Mm (0.002 In)

Conrod crank pin bearing removal and

installation

Conrod crank pin bearing removal and

installation

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Removal

Remove the conrod crank pin bearings (1).

Note

do not remove the beari ...

Conrod crank pin bearing inspection and

selection

Conrod crank pin bearing inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect the bearing surfaces for any signs of fusion,

pitting, burn or flaws. If ...

Other materials:

Engine coolant solution

Use engine coolant that is com·

patible with an aluminum radiator,

mixed with distilled water at a

50:50 mixture ratio for engine

coolant solution. An engine coolant

mixture other than 50:50 can

affect cooling efficiency or rust

inhibiting performance.

Engine coolant

Engine coolant should b ...

Injection timing description

Injection time (injection volume)

The factors to determine the injection time include the basic fuel injection

time, which is calculated on the basis of the

intake air pressure, engine speed and throttle opening angle, and various

compensations. These compensations are

determined according to ...

Windshield cleaning

Clean the windshield with soft

cloth and warm water with mild

detergent. If scratched, polish

with a commercially available

plastic polish. Replace the windshield

if it becomes scratched or

discolored so as to obstruct view.

When replacing the windshield,

use suzuki replacement windshield. ...