Suzuki GSX-R 1000 Service Manual: Conrod crank pin bearing inspection and selection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Inspection

- Inspect the bearing surfaces for any signs of fusion, pitting, burn or flaws. If any, replace them with a specified set of bearings.

- Place the plastigauge axially along the crank pin, avoiding the oil hole, as shown in the figure.

Special tool

(a): 09900–22301 (plastigage (0.025

(a): 09900–22301 (plastigage (0.025

– 0.076

Mm))

- Tighten the conrod cap bolts to the specified torque, in two stages.

Note

|

Tightening torque conrod cap bolt: 37 n·m (3.7 Kgf-m, 26.5 Ib-ft) then turn in 1/6 (60°) turn

- Remove the conrod cap bolts and measure the width

of the compressed plastigauge using the envelope

scale. This measurement should be taken at the

widest part of the compressed plastigauge.

If the oil clearance exceeds the service limit, select the specified bearings from the bearing selection table.

Special tool

(a): 09900–22301 (plastigage (0.025

(a): 09900–22301 (plastigage (0.025

– 0.076

Mm))

Conrod big end oil clearance standard: 0.040 – 0.064 Mm (0.0016 – 0.0025 In)

Conrod big end oil clearance service limit: 0.080 Mm (0.0031 In)

Selection

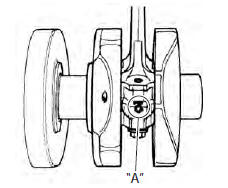

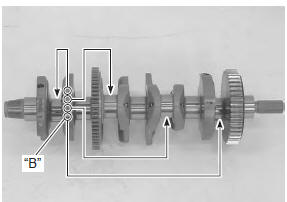

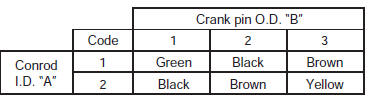

- Check the corresponding conrod i.D. Code numbers ([1] or [2]) “a”.

Conrod i.D. Specification

- Check the corresponding crank pin o.D. Code numbers ([1], [2] or [3]) “b”.

- Measure the conrod crank pin o.D. With the special tool. If any of the measurements are out of specification, replace the crankshaft.

Crank pin o.D. Specification

Special tool

(a): 09900–20202 (micrometer (25 –

(a): 09900–20202 (micrometer (25 –

50

mm))

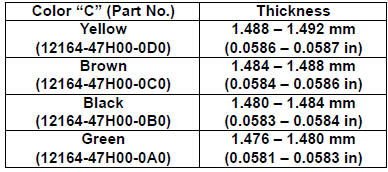

- Select the specified bearings from the bearing selection table.

| Caution the bearings should be replaced as a set. |

Bearing selection table

Bearing thickness specification

|

Conrod and crankshaft inspection

Conrod and crankshaft inspection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Conrod small end I.D.

Measure the conrod small end inside diameter using the

small bore gauge.

...

Crankshaft journal bearing inspection and

selection

Crankshaft journal bearing inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect each upper and lower crankcase bearing for

any damage.

Set ...

Other materials:

Transmission related parts inspection

Refer to “transmission removal” , “transmission installation” and

“countershaft gear / driveshaft gear disassembly and assembly” .

Gearshift fork to groove clearance

Note

the clearance for each gearshift fork plays

an important role in the smoothness and

positiveness of the ...

Rear brake hose routing diagram

Hose clamp

: face the clamp end backward.

Stopper

: after the brake hose union has contacted

to the stopper, tighten the union bolt.

Brake pad pin

Plug

Caliper sliding pin b

Caliper sliding pin a

White marking

Yellow marking

Pass the

...

Engine sprocket removal and installation

Removal

Remove the gearshift link arm (1) from the gearshift

shaft.

Note

mark the gearshift shaft head at which the

gearshift link arm slit set for correct

reinstallation.

Remove the speed sensor (2).

Remove the engine sprocket cover (3).

Support the ...