Suzuki GSX-R 1000 Service Manual: Countershaft gear / driveshaft gear disassembly and assembly

Refer to “transmission removal” and “transmission installation” .

Disassembly

| Caution identify the position of each removed part. Organize the parts in their respective groups (i.E., Drive or driven) so that they can be reinstalled in their original positions. |

Countershaft

Disassemble the countershaft as shown in the transmission construction. Refer to “transmission construction” .

Pay attention to the following points:

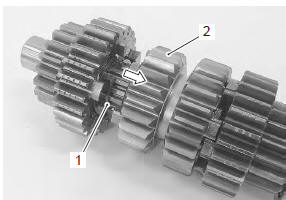

- remove the 6th drive gear snap ring (1) from its groove and slide it towards the 3rd/4th drive gears (2).

Special tool

: 09900–06104 (snap ring remover

: 09900–06104 (snap ring remover

(open

type))

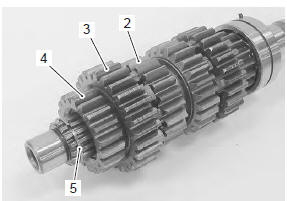

- Slide the 6th (3) and 2nd (4) drive gears toward the 3rd/4th drive gears (2), then remove the 2nd drive gear circlip (5).

- Remove the 2nd drive gear (4) and 6th drive gear (3).

- Remove the countershaft bearing (6) using hydraulic press.

Driveshaft

- Disassembly the driveshaft as shown in the transmission construction. Refer to “transmission construction” .

Assembly

| Note when reassembling the transmission gears, attention must be given to the locations and positions of washers and snap rings. The cross sectional view shows the correct position of the gears, bushings, washers and snap rings. Refer to “transmission construction” . |

Caution

|

Note

|

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- When installing a new snap ring (1), pay attention to its direction. Fit it to the side where the thrust is as shown in the figure.

|

Driveshaft

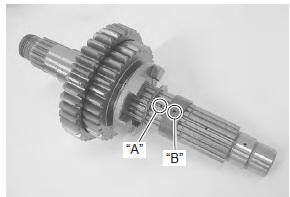

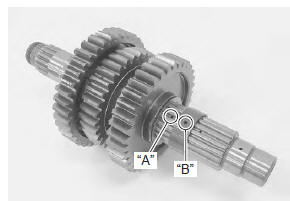

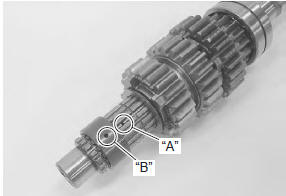

- When installing the gear bushings onto the driveshaft, align the shaft oil holes “a” with the bushing oil hole “b”.

Countershaft

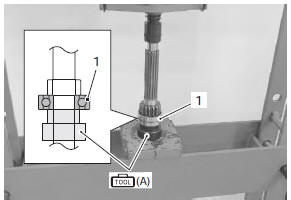

- Install the countershaft bearing (1) using a hydraulic press and special tool.

Special tool

(a): 09913–70210 (bearing

(a): 09913–70210 (bearing

installing set (10

– 75 Ô))

- When installing the gear bushing onto the countershaft, align the shaft oil hole “a” with the bushing oil hole “b”.

Transmission construction

Transmission construction

Countershaft

Driveshaft

...

Transmission related parts inspection

Transmission related parts inspection

Refer to “transmission removal” , “transmission installation” and

“countershaft gear / driveshaft gear disassembly and assembly” .

Gearshift fork to groove clearance

Note

the clear ...

Other materials:

Transmission installation

Install the transmission in the reverse order of removal.

Pay attention to the following points:

Bearing and oil seal

Caution

replace the removed bearings and oil seals

with new ones.

Install the driveshaft left bearing oil seal into the

retainer using the special tool.

...

Drive chain adjustment

Inspect the drive chain slack

before each use of the motorcycle.

Place the motorcycle on the

side stand. The drive chain

should be adjusted for 20 - 30

mm (0.8 - 1.2 In) of slack, as

shown.

Warning

Too much chain slack can

cause the chain to come off the

sprockets, resul ...

Exhaust system components

Exhaust pipe gasket

Exhaust pipe assembly

Ho2 sensor

Connector

: install the connector so that the

chamfer side faces backward.

Muffler chamber

Muffler body

Excv cable no. 1

Excv cable no. 2

When loosening or tightening the pulley bol ...