Suzuki GSX-R 1000 Service Manual: DTC “c22” (p1450-h/l): ap sensor circuit

malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

| C22 |

Ap sensor voltage is not within the

following range.

0.5 V ≤ Sensor voltage < 4.85 V

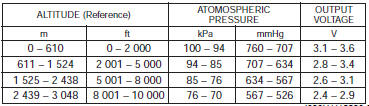

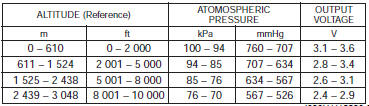

| Note

note that atmospheric pressure

varies depending on weather

conditions as well as altitude.

Take that into consideration

when inspecting voltage. |

|

- Clogged vacuum passage with dust.

- Ap sensor circuit open or shorted to ground.

- Ap sensor malfunction.

- Ecm malfunction.

- Ap sensor circuit is open or shorted to vcc or ground

circuit open.

- Ap sensor circuit is shorted to ground or vcc circuit

open.

|

| P1450 |

H |

Sensor voltage is higher than specified

value. |

|

L |

Sensor voltage is lower than specified

value. |

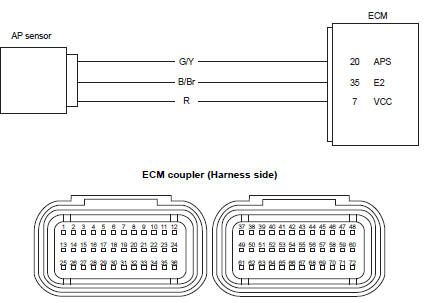

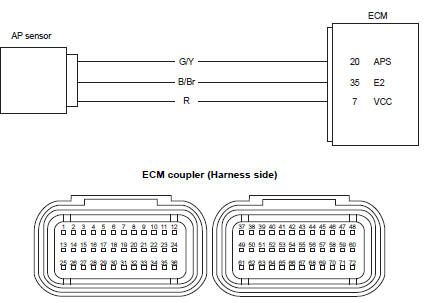

Wiring diagram

Troubleshooting

| Caution

when using the multi-circuit tester, do not strongly touch the terminal

of the ecm coupler with a

needle pointed tester probe to prevent terminal damage. |

| Note

after repairing the trouble, clear the dtc using sds tool. Refer to “use

of sds diagnosis reset procedures” . |

C22 (use of mode select switch)

|

Step |

Action |

Yes |

No |

|

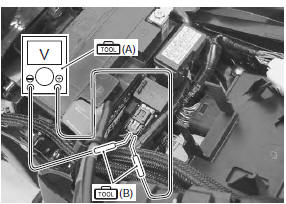

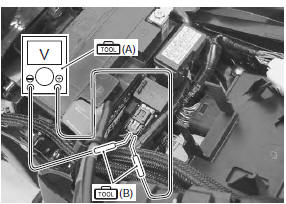

1 |

- Turn the ignition switch off.

- Remove the front seat. Refer to “exterior parts removal and

installation” in section 9d .

- Remove the starter relay from the bracket.

- Check the ap sensor coupler (1) for loose or poor

contacts.

If ok, then measure the ap sensor input voltage.

- Disconnect the ap sensor coupler.

- Turn the ignition switch on.

- Measure the input voltage between the r wire and

ground.

If ok, then measure the voltage between the r wire and

b/br wire.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

voltage (  ) )

Ap sensor input voltage

4.5 – 5.5 V

((+) terminal: r – (–) terminal: ground, (+) terminal: r

– (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. |

- Loose or poor

contacts on the ecm

couplers.

- Open or short circuit

in the r or b/br wire.

|

P1450-h (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

- Turn the ignition switch off.

- Remove the front seat. Refer to “exterior parts removal and

installation” in section 9d .

- Remove the starter relay from the bracket.

- Check the ap sensor coupler (1) for loose or poor

contacts.

If ok, then check the ap sensor lead wire continuity.

- Disconnect the ap sensor coupler.

- Check the continuity between the r wire and g/y wire.

If the sound is not heard from the tester, the circuit

condition is ok.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

continuity ( ) )

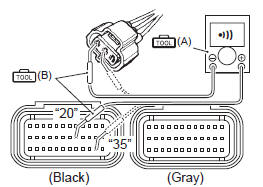

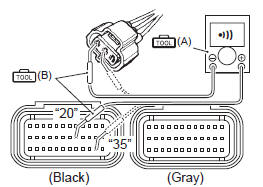

- Disconnect the ecm couplers. Refer to “ecm removal and

installation” in section 1c .

- Insert the needle pointed probes to the lead wire coupler.

- Check the continuity between the g/y wire and terminal

“20”.

If ok, then check the continuity between the b/br wire

and terminal “35”.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

(b): 09900–25009 (b): 09900–25009

(needle-point probe set)

Tester knob indication

continuity test ( ) )

Ecm coupler (harness side)

Is the continuity ok? |

Go to step 3. |

G/y wire shorted to

vcc, or b/br wire open. |

P1450-l (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

- Turn the ignition switch off.

- Remove the front seat. Refer to “exterior parts removal and

installation” in section 9d .

- Remove the starter relay from the bracket.

- Check the ap sensor coupler (1) for loose or poor

contacts.

If ok, then check the ap sensor lead wire continuity.

- Disconnect the ap sensor coupler.

- Check the continuity between the g/y wire and ground.

Also, check the continuity between the g/y wire and b/

br wire. If the sound is not heard from the tester, the

circuit condition is ok.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

continuity ( ) )

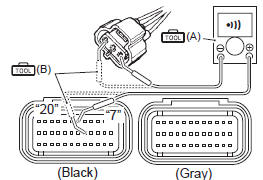

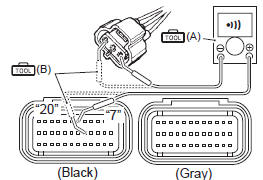

- Disconnect the ecm couplers. Refer to “ecm removal and

installation” in section 1c .

- Insert the needle pointed probes to the lead wire coupler

- Check the continuity between the r wire and terminal

“7”. Also, check the continuity between the g/y wire and

terminal “20”.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

v(b): 09900–25009 (needle-point probe set)

Tester knob indication

continuity ( ) )

Ecm coupler (harness side)

Is the continuity ok? |

Go to step 2. |

R and g/y wire open, g/

y wire shorted to

ground. |

|

2 |

- Connect the ecm couplers.

- Turn the ignition switch on.

- Measure the input voltage between the r wire and

ground.

If ok, then measure the voltage between the r wire and

b/br wire.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

voltage ( ) )

Ap sensor input voltage

4.5 – 5.5 V

((+) terminal: r – (–) terminal: ground, (+) terminal: r

– (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. |

- Loose or poor

contacts on the ecm

couplers.

- Open or short circuit

in the r or b/br wire.

|

|

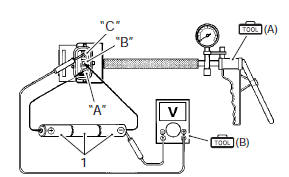

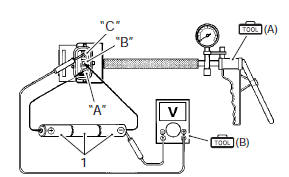

3 |

- Turn the ignition switch off.

- Connect the ecm couplers and ap sensor coupler.

- Insert the needle pointed probes to the lead wire coupler.

- Run the engine at idle speed and measure the ap

sensor output voltage between the g/y wire and b/br

wire.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

(b): 09900–25009 (b): 09900–25009

(needle-point probe set)

Tester knob indication

voltage (  ) )

Ap sensor output voltage

approx. 3.6 V at 100 kpa (760 mmhg)

((+) terminal: g/y – (–) terminal: b/br)

Is the voltage ok? |

Go to step 4. |

- Check the vacuum

port for crack or

damage.

- Open or short circuit

in the g/y wire.

- If vacuum hose and lead wire are ok, replace the ap sensor with

a new one. Refer to “ap sensor removal and installation” in section

1c .

|

|

4 |

- Turn the ignition switch off.

- Remove the ap sensor. Refer to “ap sensor removal and

installation” in section 1c .

- Connect the vacuum pump gauge to the vacuum port of

the ap sensor.

- Arrange 3 new 1.5 V batteries in series (1) (check that

total voltage is 4.5 – 5.0 V) and connect (–) terminal to

the ground terminal “b” and (+) terminal to the vcc

terminal “a”.

- Check the voltage between vout terminal “c” and

ground. Also, check if voltage reduces when vacuum is

applied up to 53 kpa (400 mmhg) by using vacuum

pump gauge.

Special tool

(a): 09917–47011 (vacuum (a): 09917–47011 (vacuum

pump gauge set)

(b): 09900–25008 (multi (b): 09900–25008 (multi

circuit tester set)

Tester knob indication

voltage (  ) )

Is the voltage ok? |

- G/y, r or b/br wire

open or shorted to

ground, or poor “7”,

“20” or “35”

connection.

- If wire and

connection are ok,

intermittent trouble or

faulty ecm.

- Recheck each

terminal and wire

harness for open

circuit and poor

connection.

- Replace the ecm with a known good one, and inspect it again.

Refer to “ecm removal and installation” in section 1c .

|

If check result is not satisfactory, replace the ap sensor with a

new one. Refer to “ap sensor removal and installation” in section 1c . |

Detected condition and possible cause

Detected condition

Possible cause

C21

Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < ...

Detected condition and possible cause

Detected condition

Possible cause

C23

The sensor voltage should be the

following for 2 sec. And more, after ignition

switch i ...

Other materials:

Cam chain guide / cam chain tensioner

removal and installation

Removal

Remove the cylinder head cover. Refer to “engine top side disassembly” .

Remove the cam chain guide no. 2 (1).

Remove the cylinder head. Refer to “engine top side disassembly”

and “engine bottom side disassembly” .

Remove the starter clutch. Refer to “s ...

Front wheel dust seal / bearing removal and installation

Removal

Remove the front wheel assembly. Refer to “front wheel assembly removal

and installation” .

Remove the dust seals using the special tool.

Special tool

(a): 09913–50121 (oil

seal remover)

Remove the wheel bearings using the special tool.

Special tool

(b): 099 ...

Rear wheel removal

Place the motorcycle on the

side stand.

Remove the cotter pin 1.

Remove the axle nut 2.

Warning

A hot muffler can burn you.

The muffler will be hot enough

to burn you for some time after

stopping the engine.

Wait until the muffler cools to

avoid bur ...

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction DTC “c23” (p1651-h/l): to sensor circuit

malfunction

DTC “c23” (p1651-h/l): to sensor circuit

malfunction

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)