Suzuki GSX-R 1000 Service Manual: Dtc “c36” (p1764), “c37” (p1765), “c38” (p1766) or “c39” (p1767): secondary fuel injector circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

| Some failure exists in the fuel injector signal in a high load, high revolution condition. |

|

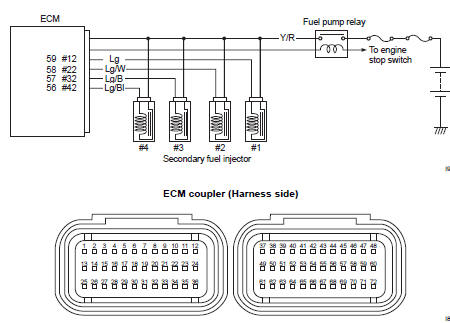

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

|

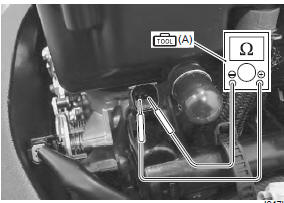

1 |

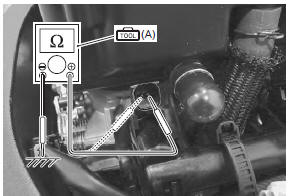

Special tool Tester knob indication resistance (Ω) Injector resistance 11 – 13 Ω at 20 °c (68 °f) (terminal – terminal)

Special tool Injector continuity ∞Ω¶ (infinity)

Are the resistance and continuity ok? |

Go to step 2. | Replace the injector with a new one. Refer to “throttle body disassembly and assembly” in section 1d . | |

|

2 |

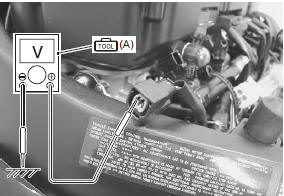

Special tool Tester knob indication

voltage ( Injector voltage battery voltage ((+) terminal: y/r – (–) terminal: ground)

Is the voltage ok? |

|

Open circuit in the y/r wire. |

Dtc “c32” (p0201), “c33” (p0202), “c34” (p0203) or “c35” (p0204): primary

fuel injector circuit

malfunction

Dtc “c32” (p0201), “c33” (p0202), “c34” (p0203) or “c35” (p0204): primary

fuel injector circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

Ckp signal is produced but fuel injector signal is

interrupted by 4 times or more continuity

...

DTC “c40” (p0505 / p0506 / p0507): isc

valve circuit malfunction

DTC “c40” (p0505 / p0506 / p0507): isc

valve circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

C40/P0505

The circuit voltage of motor drive is

unusual.

Isc valve circuit open or ...

Other materials:

Precautions

Precautions for exhaust system

To avoid

the risk of being burned, do not touch the exhaust system when the

system is hot. Any

service on the exhaust system should be performed when the system is

cool.

Caution

make sure that the exhaust pipes and muffler ...

Headlight bulb and position light bulb

replacement

Caution

when you touch the bulb with your bare

hands, clean the bulb with a cloth moistened

with alcohol or soap water to prevent

premature bulb failure.

Low beam bulb

Remove the combination meter. Refer to “combination meter removal and

installation” in section 9c .

...

Specifications

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Body frame construction” “front footrest bracket construction”

“side-stand construction”

Reference: for the tightening torque of fastener not specified in this ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)