Suzuki GSX-R 1000 Service Manual: DTC “c40” (p0505 / p0506 / p0507): isc valve circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

|

| C40/P0505 | The circuit voltage of motor drive is unusual. |

|

| C40/P0506 | Idle speed is lower than the desired idle speed. | |

| C40/P0507 | Idle speed is higher than the desired idle speed. | |

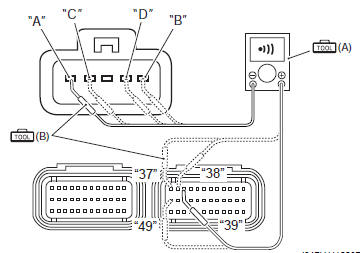

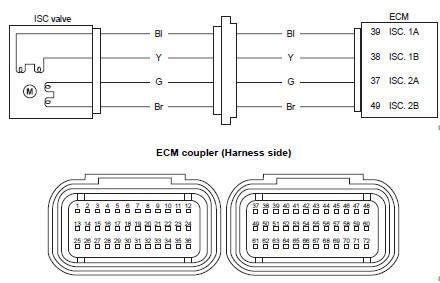

Wiring diagram

Troubleshooting

Caution

|

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

1 |

Special tool Tester knob indication

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | Bl, y, g or br wire open |

|

2 |

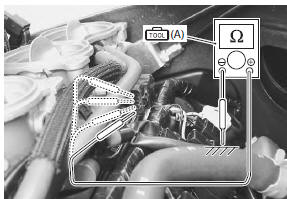

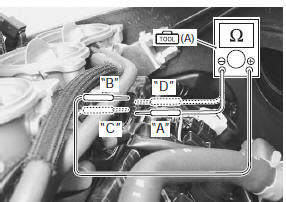

Special tool

Tester knob indication resistance (Ω) Isc valve continuity ∞Ω¶ (infinity) (terminal . Ground)

Isc valve resistance approx. 80 Ω at 20 °c (68 °f) (terminal: “a” – terminal: “b”, terminal: “c” – terminal: “d”)

Is the resistance ok? |

If wire is ok, intermittent trouble or faulty ecm. | Replace the isc valve with a new one. Refer to “throttle body removal and installation” in section 1d (page 1d- 10). |

Active control inspection (isc rpm control)

Check 1

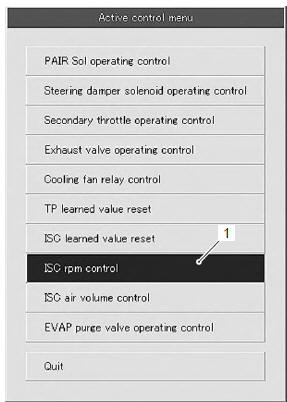

- Set up the sds tool. (Refer to the sds operation manual for further details.)

- Check that the engine is running.

- Click the “active control”.

- Click the “isc rpm control” (1).

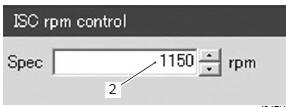

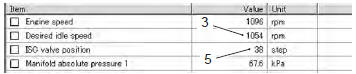

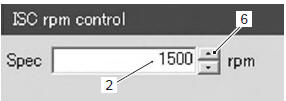

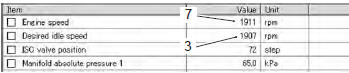

- Check that the “spec” (2) is idle speed 1 150 ± 100 rpm.

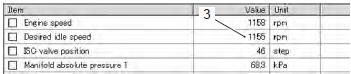

- Check that the “desired idle speed” (3) is within the specified idle rpm.

Check 2

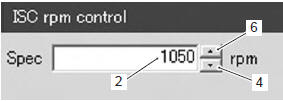

- Click the button (4) and decrease the “spec” (2) to 1 050 rpm slowly.

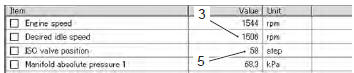

- Check that the “desired idle speed” (3) is nearly equal to the “spec” (2). At the same time, check that the number of steps (5) in the isc valve position decreases.

- Click the button (6) and increase the “spec” (2) slowly.

- Check that the “desired idle speed” (3) is nearly equal to the “spec” (2). Also, check that the number of steps (5) in the isc valve position increases.

Check 3

- Click the button (6) and increase the “spec” (2) to 1 500 rpm slowly.

- Check that the “desired idle speed” (3) is nearly equal to the “spec” (2). Also, check that the number of steps (5) in the isc valve position increases.

Check 4

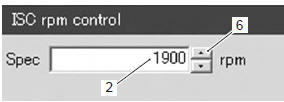

- Click the button (6) and increase the “spec” (2) to 1 900 rpm.

- Check that the “desired idle speed” (3) is approx. 1 900 Rpm.

- Check that the “engine speed” (7) is close to 1 900 rpm.

| Note be careful not to increase the “spec” to 2 000 rpm, or the “engine speed” may reach the upper limit. |

If the isc valve does not function properly, inspect the isc valve or replace the isc valve. Refer to “dtc “c40” (p0505 / p0506 / p0507): isc valve circuit malfunction” or “throttle body disassembly and assembly” in section 1d .

Dtc “c36” (p1764), “c37” (p1765), “c38” (p1766) or “c39” (p1767): secondary

fuel injector circuit

malfunction

Dtc “c36” (p1764), “c37” (p1765), “c38” (p1766) or “c39” (p1767): secondary

fuel injector circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

Some failure exists in the fuel injector signal in a high

load, high revolution condition.

...

DTC “c41” (p0230-h/l): fp relay circuit

malfunction

DTC “c41” (p0230-h/l): fp relay circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C41

No voltage is applied to fuel pump.

Fuel pump relay circuit open or short.

...

Other materials:

DTC “c31” (p0705): gp switch circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

No gear position switch voltage

Gp switch voltage is not within the following range.

Gp switch voltage > 0.6 V

Gp switch circuit open or short.

Gp switch malfunction.

...

Rear brake pad inspection

The extent of brake pads wear can be checked by observing the grooved limit

line “a” on the pads. When the wear exceeds the grooved limit line, replace the

pads with new ones. Refer to “rear brake pad replacement” .

Caution

replace the brake pad as a set, otherwise

braking performa ...

Sds check

Using sds, sample the data at the time of new and periodic vehicle

inspections.

After saving the sampled data in the computer, file them by model and by user.

The periodically filed data help improve the accuracy of troubleshooting since

they can indicate the condition of vehicle

function ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

)