Suzuki GSX-R 1000 Service Manual: DTC “c44” (p0130/p0135): ho2 sensor (ho2s) circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

|

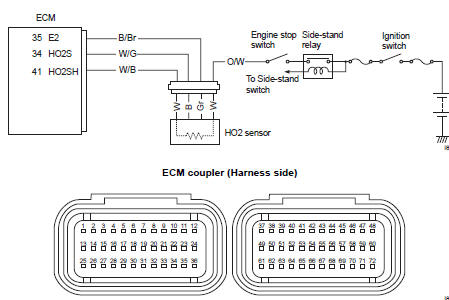

| C44/P0130 | Ho2 sensor output voltage is not input to

ecm during engine operation and running

condition. Sensor voltage > 1.0 V |

|

| C44/P0135 | The heater can not operate so that heater operation voltage is not supplied to the oxygen heater circuit. | |

Wiring diagram

Troubleshooting (when indicating c44/p0130:)

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

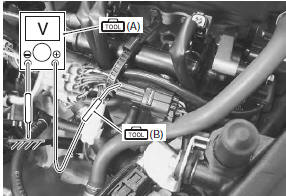

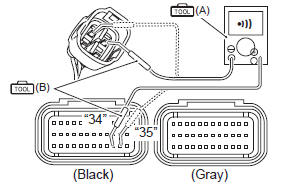

1 |

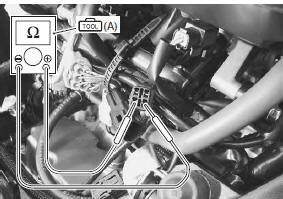

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

continuity ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | W/g wire shorted to the power source, or w/g or b/br wire open. |

|

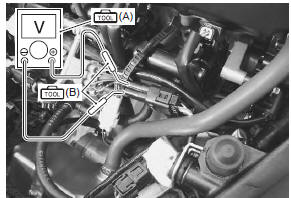

2 |

Special tool Tester knob indication

voltage ( Ho2 sensor output voltage at idle speed 0.3 V and less ((+) terminal: w/g (b) – (–) terminal: b/br (gr))

Ho2 sensor output voltage at 5 000 r/min 0.6 V and more ((+) terminal: w/g – (–) terminal: b/br) Is the voltage ok? |

|

Replace the ho2

sensor with a new one. Refer to “ho2 sensor removal and installation” in section 1c . |

Troubleshooting (when indicating c44/p0135:)

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

|

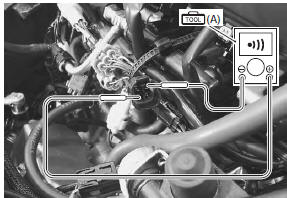

1 |

Special tool Tester knob indication resistance (Ω) Ho2 sensor heater resistance 6.7 – 9.5 Ω at 23 °c (73 °f) (w – w)

Is the resistance ok? |

Go to step 2. | Replace the ho2

sensor with a new one. Refer to “ho2 sensor removal and installation” in section 1c . |

|

|

2 |

Special tool Tester knob indication

voltage ( Heater voltage battery voltage ((+) terminal: w/b – (–) terminal: ground)

Is the voltage ok? |

|

|

DTC “c42” (p1650): ig switch circuit

malfunction

DTC “c42” (p1650): ig switch circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

Ignition switch signal is not input to the ecm.

Ignition system circuit open or short.

...

DTC “c46” (p1657-h/l or p1658): excv

actuator circuit malfunction

DTC “c46” (p1657-h/l or p1658): excv

actuator circuit malfunction

Detected condition

Possible cause

C46

The operation signal does not reach the

excv actuator.

Excva position sensor voltage low or

high

0.14 V ≤ Sensor v ...

Other materials:

Specifications

Service data

Fi sensors

Tightening torque specifications

Reference: for the tightening torque of fastener not specified in this

section, refer to “tightening torque list” in section 0c . ...

Spring pre-load adjustment

To change the spring pre-load,

turn the adjuster 1 clockwise or

counterclockwise. Turning the

adjuster clockwise will increase

the spring pre-load. Turning the

adjuster counterclockwise will

decrease the spring pre-load.

There are five grooved lines on

the side of the adjuster 1 for re ...

Country and area codes

The following codes stand for the applicable country(-ies) and area(-s).

Wire color symbols

Warning, caution and information labels location

Noise label

Information label

Vacuum hose routing label

Fuel information label

Manual notice label

Screen la ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

)