Suzuki GSX-R 1000 Service Manual: DTC “c46” (p1657-h/l or p1658): excv

actuator circuit malfunction

|

Detected condition |

Possible cause |

| C46 |

The operation signal does not reach the

excv actuator.

Excva position sensor voltage low or

high

0.14 V ≤ Sensor voltage < 4.9 V

(without the above range)

excva can not operate properly. |

- Excva maladjusted.

- Excva circuit open or short.

- Excva motor malfunction.

- Excva position sensor malfunction.

- Excva position sensor circuit shorted to vcc or ground

circuit open.

- Excva position sensor circuit open or shorted to ground

or vcc circuit open.

- Excva motor circuit open or short.

- Excva motor malfunction.

|

| P1657 |

H |

Sensor voltage is higher than specified

value. |

| L |

Sensor voltage is lower than specified

value. |

| P1658 |

The operation signal does not reach the

excva motor.

Excva can not operate properly. |

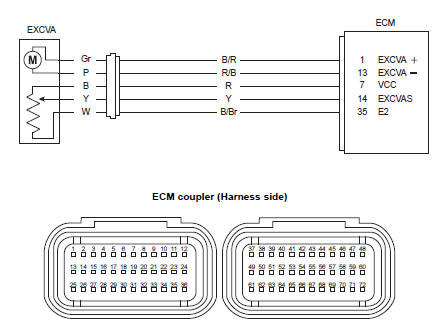

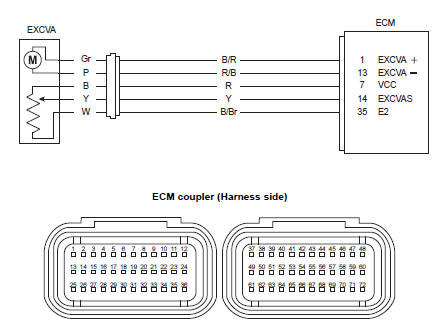

Wiring diagram

Troubleshooting

| Caution

when using the multi-circuit tester, do not strongly touch the terminal

of the ecm coupler with a

needle pointed tester probe to prevent terminal damage. |

| Note

after repairing the trouble, clear the dtc using sds tool. Refer to “use

of sds diagnosis reset procedures” . |

C46 (use of mode select switch)

|

Step |

Action |

Yes |

No |

|

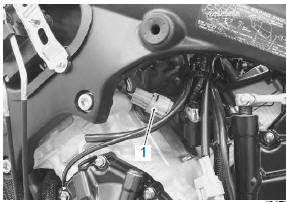

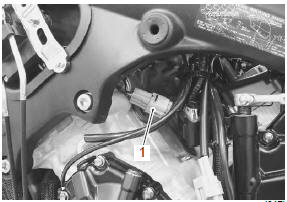

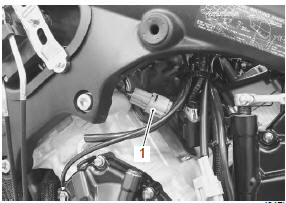

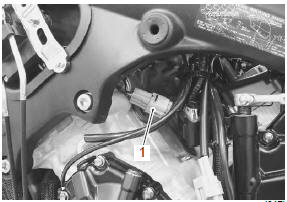

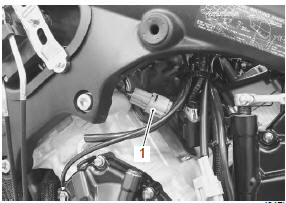

1 |

- Turn the ignition switch off.

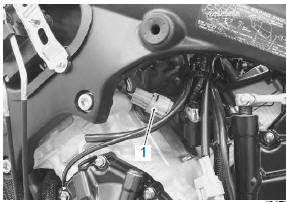

- Remove the left side cowling. Refer to “exterior parts removal

and installation” in section 9d .

- Check the excva coupler (1) for loose or poor contacts.

- Turn the ignition switch on.

- Check the operation of the excva.

(Excva operation order: full close →

full open →

approx. 80% Open)

Is the operation ok? |

Go to step 2. |

Go to step 6. |

P1657-h (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

- Turn the ignition switch off.

- Remove the left side cowling. Refer to “exterior parts removal

and installation” in section 9d .

- Check the excva coupler (1) for loose or poor contacts.

If ok, then check the excva position sensor lead wire

continuity.

- Disconnect the excva coupler.

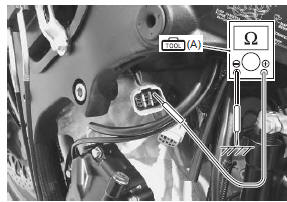

- Check the continuity between r wire and y wire.

If the sound is not heard from the tester, the circuit

condition is ok.

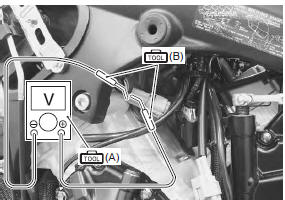

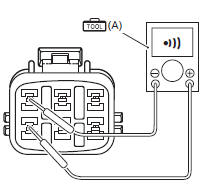

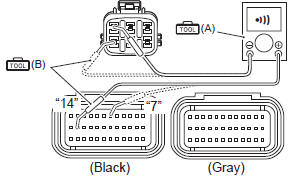

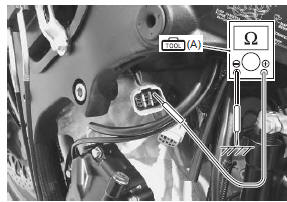

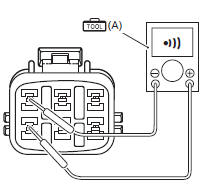

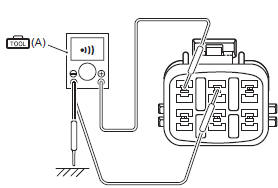

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

continuity (  ) )

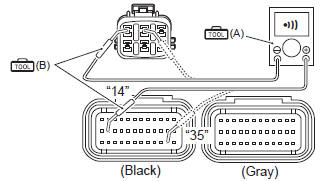

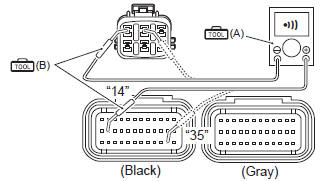

- Disconnect the ecm couplers.

- Check the continuity between y wire and terminal “14”.

- Also, check the continuity between b/br wire and

terminal “35”.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

(b): 09900–25009 (b): 09900–25009

(needle-point probe set)

Tester knob indication

continuity (  ) )

Excva lead wire continuity

continuity (  ) )

Ecm couplers (harness side)

Is the continuity ok? |

Go to step 4. |

Y wire shorted to vcc,

or b/br wire open. |

P1657-l (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

- Turn the ignition switch off.

- Remove the left side cowling. Refer to “exterior parts removal

and installation” in section 9d .

- Check the excva coupler (1) for loose or poor contacts.

If ok, then check the excva position sensor lead wire

continuity.

- Disconnect the excva coupler.

- Check the continuity between y wire and ground.

- Also, check the continuity between y wire and b/br wire.

If the sound is not heard from the tester, the circuit

condition is ok.

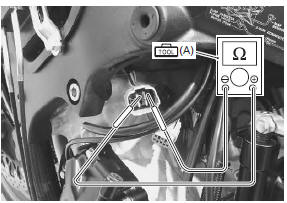

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

voltage ( ) )

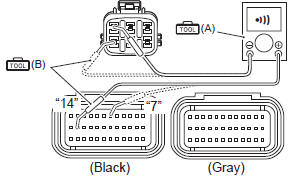

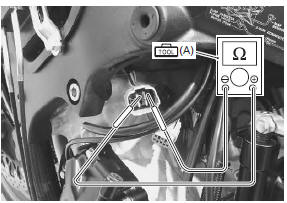

- Disconnect the ecm coupler.

- Check the continuity between y wire and terminal “14”.

- Also, check the continuity between r wire and terminal

“7”.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

(b): 09900–25009 (b): 09900–25009

(needle-point probe set)

Tester knob indication

continuity (  ) )

Excva lead wire continuity

continuity (  ) )

Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2 and go to

step 4. |

R or y wire open, or y

wire shorted to ground. |

P1658 (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

- Turn the ignition switch off.

- Remove the left side cowling. Refer to “exterior parts removal

and installation” in section 9d .

- Check the excva coupler (1) for loose or poor contacts.

Is the connection ok? |

Go to step 6. |

Loose or poor contacts

on the excva coupler. |

|

2 |

- Turn the ignition switch off.

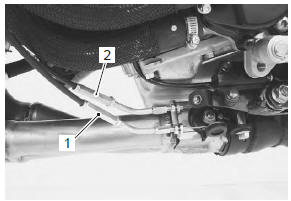

- Check the installation of excv cables. If it is necessary,

adjust the excv cables. Refer to “excv cable removal and

installation” in section 1k .

- Disconnect the excva coupler (1).

- Turn the ignition switch on.

- Measure the voltage between the r wire and ground.

- If ok, then measure the voltage between the r wire and

b/br wire.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Tester knob indication

voltage ( ) )

Excva position sensor input voltage

4.5 – 5.5 V

((+) terminal: r – (–) terminal: ground)

((+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. |

- Loose or poor

contacts on the ecm

coupler (terminal “7”

or “35”).

- Open or short circuit

in the r or b/br wire.

|

|

3 |

- Turn the ignition switch off.

- Check the continuity between y wire and ground.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

Excva position sensor continuity

∞Ω¶ (infinity)

- If ok, then measure the excva position sensor

resistance.

- Connect the excva coupler and set the excva to adjustment

position. Refer to “excv cable removal and installation” in section

1k .

- Disconnect the excva coupler and measure the

resistance between y and w wires.

Special tool Special tool

(a): 09900–25008 (multi circuit tester set)

Tester knob indication

resistance (Ω)

Excva position sensor resistance at adjustment

position

approx. 3.1 KΩ

((+) y – (–) w)

Is the resistance ok? |

Go to step 4. |

Replace the excva

with a new one. |

|

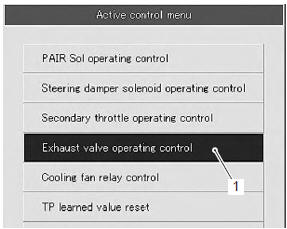

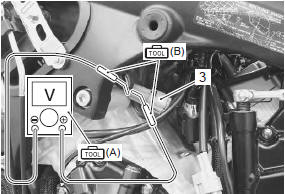

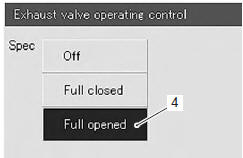

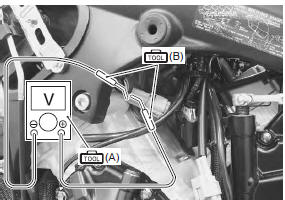

4 |

- Turn the ignition switch off.

- Connect the excva coupler.

- Set up the sds tools. Refer to “self-diagnostic procedures” .

- Turn the ignition switch on.

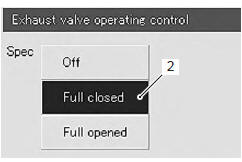

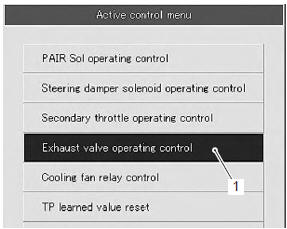

- Click “exhaust valve operating control” (1).

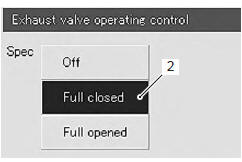

- Click “full closed” (2).

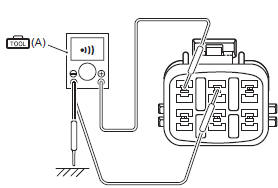

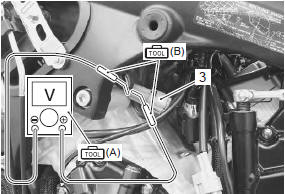

- Insert the needle pointed probes into the back side of the

excva coupler (3). ((+) Y – (–) w)

- measure the excva position sensor output voltage at

excv fully closed position.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

(b): 09900–25009 (b): 09900–25009

(needle-point probe set)

Tester knob indication

voltage (  ) )

Excva position sensor output voltage

excv is fully closed: 0.45 – 1.4 V

((+) y – (–) w)

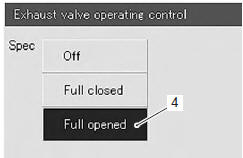

- Click “full opened” (4).

- Measure the excva position sensor output voltage at

excv fully opened position.

Special tool

(a): 09900–25008 (multi (a): 09900–25008 (multi

circuit tester set)

(b): 09900–25009 (b): 09900–25009

(needle-point probe set)

Excva position sensor output voltage

excv is fully opened: 3.6 – 4.55 V

((+) y – (–) w)

Is the voltage ok? |

Replace the ecm with a

known good one, and

inspect it again. |

Go to step 5. |

|

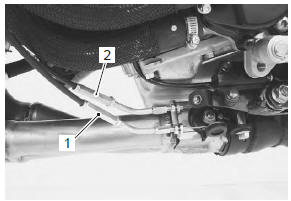

5 |

- If the excva position sensor output voltage is 0.45 V and less

at excv fully closed position, adjust the output voltage to the

specified value by turning the no. 1 Cable adjuster (1). Refer to

“excv cable removal and installation” in section 1k .

- Repeat the procedure in step 4 until the output voltage is

set within the specified value. (If c46/p1657 code is

indicated after adjusting the voltage, increase the

voltage to 0.9 V).

Caution

- adjusting the cable with the excv fully opened or fully

closed can damage the excva. Be sure to adjust the cable

with the excv set in the adjustment position. Refer to “excv

cable removal and installation” in section 1k .

- Do not turn the excva pulley using a wrench.

|

- If the excva position sensor output voltage is 4.55 V and more

at excv fully opened position, adjust the output voltage to the

specified value by turning the no. 2 Cable adjuster (2). Refer to

“excv cable removal and installation” in section 1k . Repeat the

procedure in step 4 until the output voltage is set within

the specified value.

Excva position sensor output voltage

excv is fully closed: 0.45 ≤ Output

voltage ≤ 1.4

Excv is fully opened: 3.6 ≤ Output

voltage ≤ 4.55

Is the voltage ok? |

Replace the ecm with a

known good one, and

inspect it again. |

Replace the excva

with a new one. |

|

6 |

- Turn the ignition switch off.

- Disconnect the excva coupler (1).

- Apply 12 v to the terminals and check the operation of

excva.

- Then, switch the wires supplied 12 v and check the

operation of excva. (Check the operation of excva in

both way.)

Is the operation ok? |

- Loose or poor

contacts on the

excva or ecm

coupler (terminal “13”

or “1”).

- Open or short circuit

in the b/r wire or r/b

wire.

- If wire and

connection are ok,

intermittent trouble or

faulty ecm.

- Recheck each

terminal and wire

harness for open

circuit and poor

connection.

- Replace the ecm

with a known good

one, and inspect it

again.

|

- Replace the excva

with a new one.

- Inspect that the

excv and two cables

move smoothly.

|

Detected condition and possible cause

Detected condition

Possible cause

C44/P0130

Ho2 sensor output voltage is not input to

ecm during engine operation and running

...

Detected condition and possible cause

Detected condition

Possible cause

Pair control solenoid valve voltage is not input to ecm

Pair control solenoid valve circ ...

Other materials:

Combination meter removal and installation

Removal

Remove the combination meter mounting bolt (1).

Bushing

Disconnect the coupler (2) and remove the

combination meter assembly (3).

Installation

Install the combination meter in the reverse order of

removal.

Note

fix the boot of ...

Rear brake pedal removal and installation

Removal

Remove the master cylinder assembly. Refer to “rear brake master

cylinder assembly removal and installation” .

Disconnect the rear brake light switch lead wire coupler. Refer to

“rear brake light switch inspection” .

Remove the rear brake pedal as shown in the rear ...

Clamp

Clamp the wire harness at such positions as indicated in “wiring harness

routing diagram” in section 9a .

Bend the clamp properly so that the wire harness is

clamped securely.

In clamping the wire harness, use care not to allow it

to hang down.

Do not use wire or an ...

DTC “c44” (p0130/p0135): ho2 sensor

(ho2s) circuit malfunction

DTC “c44” (p0130/p0135): ho2 sensor

(ho2s) circuit malfunction DTC “c49” (p1656): pair control solenoid

valve circuit malfunction

DTC “c49” (p1656): pair control solenoid

valve circuit malfunction

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

) )

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009