Suzuki GSX-R 1000 Service Manual: Front brake caliper removal and installation

| Note the right and left calipers are installed symmetrically and therefore the removal procedure for one side is the same as that for the other side. |

Removal

- Drain brake fluid. Refer to “brake fluid replacement” in section 4a .

- Remove the brake hose from the caliper by removing the union bolt (1) and catch the brake fluid in a suitable receptacle.

| Note place a rag underneath the union bolt on the brake caliper to catch any spilt brake fluid. |

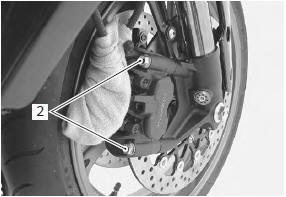

- Remove the brake caliper by removing its mounting bolts (2).

Installation

Install the brake caliper in the reverse order of removal.

Pay attention to the following points:

- tighten each bolt to the specified torque.

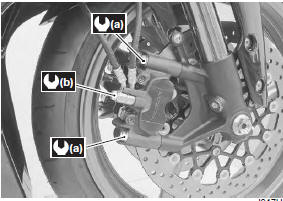

Tightening torque front brake caliper mounting bolt (a): 39 n·m (3.9 Kgf-m, 28.0 Lbf-ft)

- After setting the brake hose union to the stopper, tighten the union bolt to the specified torque.

| Caution the seal washers should be replaced with the new ones to prevent fluid leakage. |

Tightening torque brake hose union bolt (b): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft)

- Bleed air from the brake system after installing the caliper. Refer to “air bleeding from brake fluid circuit” in section 4a .

- Check the brake fluid leakage and brake operation.

Brake fluid, if it

Check the brake hose and hose joints for cracks and fluid leakage. |

Front brake pad replacement

Front brake pad replacement

Loosen the pad mounting pins (1).

Remove the brake caliper by removing the caliper

mounting bolts (2).

Remove the pad mounting pins (1), brake pads and

spring.

Caution ...

Front brake caliper disassembly and

assembly

Front brake caliper disassembly and

assembly

Refer to “front brake caliper removal and installation” .

Note

the right and left calipers are installed

symmetrically and therefore the disassembly

procedure for one side is the same ...

Other materials:

Engine coolant

Coolant level

The engine coolant solution

should be between "f" (full) and

"1..:' (Low) level lines on the engine

coolant reservoir. If the level is

lower than "1..:' (Low) level line,

bring it up to "f" (full) level by adding

50:50 mixture of distilled water ...

Precautions

Precautions for suspension

Refer to “general precautions” in section 00 (page 00-1).

All

suspensions, bolts and nuts are an important part in that it could

affect the performance of vital

parts. They must be tightened to the specified torque periodically and

if the suspension ...

Troubleshooting

This troubleshooting guide is provided

to help you find the cause of

some common complaints.

Caution

Failure to troubleshoot a problem

correctly can damage your

motorcycle. Improper repairs

or adjustments may damage

the motorcycle instead of fixing

it. Such damage may ...