Suzuki GSX-R 1000 Service Manual: Front wheel related parts inspection

Refer to “front wheel assembly removal and installation” .

Tire

Refer to “tire inspection” in section 0b .

Front brake disc

Refer to “front brake disc inspection” in section 4b .

Dust seal

Inspect the lip of dust seals for wear or damage. If any defects are found, replace the dust seal with a new one.

Refer to “front wheel dust seal / bearing removal and installation” .

Wheel axle

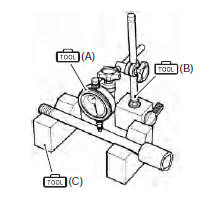

Using a dial gauge, check the wheel axle for runout. If the runout exceeds the limit, replace the axle shaft.

Special tool (a): 09900–20607 (dial gauge) (b): 09900–20701 (dial gauge chuck) (c): 09900–21304 (v blocks)

Wheel axle runout service limit: 0.25 Mm (0.010 In)

Wheel

- Remove the brake pads. Refer to “front brake pad replacement” in section 4b .

- Make sure that the wheel runout checked as shown in the figure does not exceed the service limit. An excessive runout is usually due to worn or loosened wheel bearings and can be reduced by replacing the bearings. If bearing replacement fails to reduce the runout, replace the wheel.

Wheel rim runout service limit (axial and radial): 2.0 Mm (0.08 In)

- Install the brake pads. Refer to “front brake pad replacement” in section 4b .

Wheel bearing

Inspect the play of the wheel bearings by finger while they are in the wheel. Rotate the inner race by finger to inspect for abnormal noise and smooth rotation. Replace the bearing if there is anything unusual. Refer to “front wheel dust seal / bearing removal and installation” .

Front wheel assembly removal and installation

Front wheel assembly removal and installation

Removal

Remove the brake calipers, left and right.

Caution

do not operate the brake lever with the

caliper removed.

Loosen two axle pinch bolts (1) on the right front ...

Front wheel dust seal / bearing removal and installation

Front wheel dust seal / bearing removal and installation

Removal

Remove the front wheel assembly. Refer to “front wheel assembly removal

and installation” .

Remove the dust seals using the special tool.

Special tool

(a): 09913–50121 (oil ...

Other materials:

Throtile cable play

This motorcycle has a twin throttle

cable system. Cable A is for pulling

cable and cable B is for

returning.

To adjust the cable play:

Loosen the lock nut 1.

Turn the adjuster 2 so that the

throttle grip has 2.0 - 4.0 Mm

(0.08- 0.16 In) play.Tighten the lock nut 1.

...

Front brake disc removal and installation

Removal

Remove the front wheel assembly. Refer to “front wheel assembly removal

and installation” in section 2d .

Remove the front brake disc.

Installation

Install the front brake disc in the reverse order of

removal. Pay attention to the following points:

make sure ...

Rear brake disc removal and installation

Removal

Remove the rear wheel assembly. Refer to “rear wheel assembly removal

and installation” in section 2d .

Remove the rear brake disc.

Installation

Install the rear brake disc in the reverse order of

removal. Pay attention to the following points:

make sure tha ...