Suzuki GSX-R 1000 Service Manual: Oil cooler / oil cooler hose inspection and cleaning

Refer to “exterior parts removal and installation” in section 9d .

Oil cooler hose inspection

Inspect the oil cooler hoses for any damage and oil leakage. If any defects are found, replace the oil cooler hose with a new one.

Oil cooler inspection

- Remove the oil cooler guard (1).

- Inspect the oil cooler for oil leakage. If any defects are found, replace the oil cooler with a new one. If the fins are bent or dented, repair them by carefully straightening them with the blade of a small screwdriver.

- Reinstall the removed parts.

Oil cooler cleaning

- Remove the oil cooler guard (1).

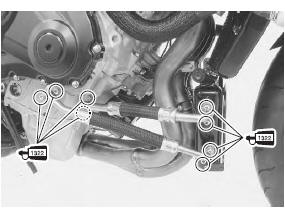

- Remove the oil cooler mounting bolts.

- Blow out any foreign matter that is stuck in the oil cooler fins using compressed air.

Caution

|

- Reinstall the removed parts.

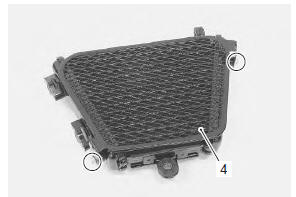

- Remove the oil cooler guard (4).

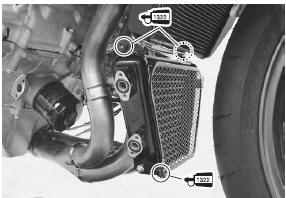

Installation

Install the oil cooler and oil cooler hoses in the reverse order of removal. Pay attention to the following points:

- apply thread lock to the oil cooler mounting bolt and tighten them securely.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Apply engine oil to new o-rings.

| Caution replace the o-rings with new ones to prevent oil leakage. |

- Apply thread lock to the oil cooler hose bolts and tighten them securely

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Pour engine oil. Refer to “engine oil and filter replacement” in section 0b .

- Install the removed parts.

Oil pressure regulator / oil strainer

inspection

Oil pressure regulator / oil strainer

inspection

Refer to “oil pan / oil pressure regulator / oil strainer removal and

installation” .

Oil pressure regulator

Inspect the operation of the oil pressure regulator by

pushing the piston with a prope ...

Oil cooler / oil cooler hose removal and

installation

Oil cooler / oil cooler hose removal and

installation

Refer to “electrical components location” in section 0a .

Removal

Turn the ignition switch off.

Remove the left side cowling. Refer to “exterior parts removal and

installation” in sect ...

Other materials:

Camshaft sprocket

Inspect the camshaft sprocket in the following

procedures:

remove the intake and exhaust camshafts. Refer to “engine top side

disassembly” .

Inspect the teeth of each camshaft sprocket for wear

or damage.

If they are worn or damaged, replace the sprocket/

camshaft assembl ...

Engine coolant temperature indicator light inspection

Inspect the engine coolant temperature meter and indicator light (led) in the

following procedures:

remove the left side cowling. Refer to “exterior parts removal and

installation” in section 9d .

Disconnect the ect sensor coupler (1).

Connect a variable resistor (2) ...

Evaporative emission control system

removal and installation (only for e-33)

Hose

removal

Lift and support the fuel tank. Refer to “fuel tank

removal and installation” in section 1g (page 1g-

9).

Remove the frame cover assembly. Refer to “exterior parts removal and

installation” in section 9d .

Remove the evap hoses as shown in the evap canister h ...