Suzuki GSX-R 1000 Service Manual: Oil pan / oil pressure regulator / oil strainer removal and installation

| Note the oil pan/oil strainer/oil pressure regulator cannot be serviced with the engine installed in the frame. |

Removal

- Remove the engine assembly from the frame. Refer to “engine assembly removal” in section 1d .

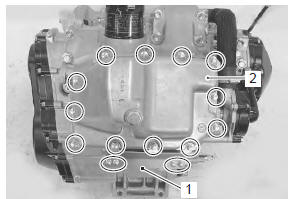

- Remove the plate (1).

- Remove the oil pan (2).

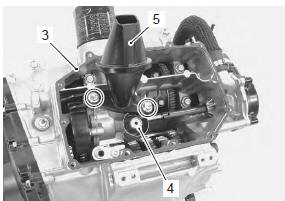

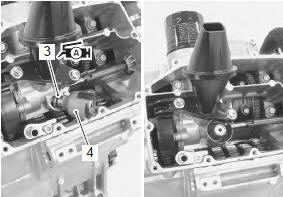

- Remove the gasket (3).

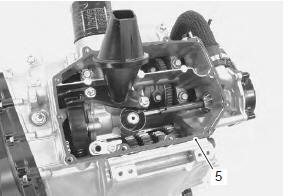

- Remove the oil pressure regulator (4) and oil strainer (5).

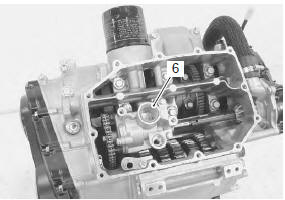

- Remove the o-ring (6).

Installation

Installation is in the reverse order of removal. Pay attention to the following points:

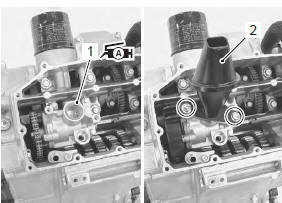

- apply grease to new o-ring (1).

| Caution use a new o-ring to prevent oil leakage. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the oil strainer (2).

- Apply grease to new o-ring (3).

| Caution use a new o-ring to prevent oil leakage. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Push in the oil pressure regulator (4) to the oil pump as shown

- Install new gasket (5).

| Caution use new gasket to prevent oil leakage. |

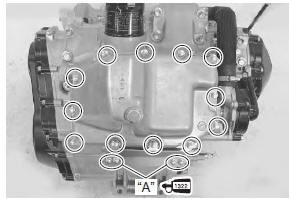

- Apply thread lock to the plate bolts “a”.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Tighten the oil pan bolts and plate bolts diagonally to the specified torque.

Tightening torque oil pan bolt: 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

Repair instructions

Repair instructions

Engine oil and filter replacement

Refer to “engine oil and filter replacement” in section 0b .

Engine oil level inspection

Refer to “engine oil and filter replacement” in section 0b . ...

Oil pressure regulator / oil strainer

inspection

Oil pressure regulator / oil strainer

inspection

Refer to “oil pan / oil pressure regulator / oil strainer removal and

installation” .

Oil pressure regulator

Inspect the operation of the oil pressure regulator by

pushing the piston with a prope ...

Other materials:

DTC “c91” (p0500): vehicle speed sensor

circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

Speedometer does not receive signal from the vehicle

speed sensor for more than 6 sec. When the motorcycle is

running. Ecm does not receive signal from the vehicle

speed sensor for more than ...

General description

Fuel injection system description

Fuel system

The fuel delivery system consists of the fuel tank (1), fuel pump (2), fuel

filter (3), fuel feed hose (4), fuel delivery pipes

(5) including fuel injectors (6) and (7), fuel pressure regulator (8). There is

no fuel return hose. The fuel in the fu ...

Wiring harness routing diagram

Wiring harness no. 2

Tapping clamp

: insert the clamp from the front side. Place the turn signal

and position light couplers in front of the clamp.

Steel clamp

: clamp the wiring harness at the blue taping point. Bend

the steel clamps to the front side.

...