Suzuki GSX-R 1000 Service Manual: Oil pump removal and installation

| Note be careful not to drop any parts into the crankcase. |

Removal

- Remove the oil pan, oil pressure regulator and oil strainer. Refer to “oil pan / oil pressure regulator / oil strainer removal and installation” .

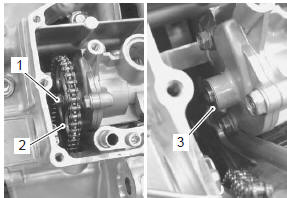

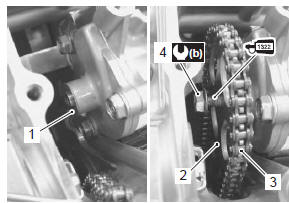

- Remove the oil pump driven gear bolt (1).

- Remove the oil pump driven sprocket (2).

- Remove the washer (3).

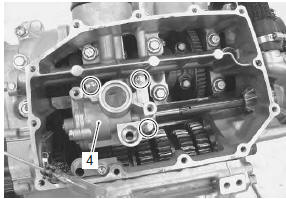

- Remove the oil pump (4).

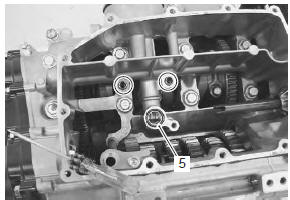

- Remove the o-ring (5) and dowel pins.

Installation

- Install the dowel pins.

- Apply grease to new o-ring.

| Caution use a new o-ring to prevent oil leakage. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the oil pump.

| Note engage the oil pump shaft end with the water pump shaft slot. |

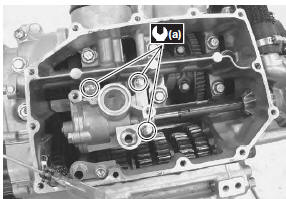

- Tighten the oil pump mounting bolts to the specified torque.

Tightening torque oil pump mounting bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Install the washer (1).

- Install the oil pump driven sprocket (2) with the chain (3).

- Apply a small quantity of thread lock to the oil pump driven sprocket bolt (4) and tighten it to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque oil pump driven sprocket bolt (b): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Install the oil pan, oil strainer and oil pressure regulator. Refer to “oil pan / oil pressure regulator / oil strainer removal and installation” .

Oil jet inspection

Oil jet inspection

Refer to “oil jet removal and installation” .

Oil jet

Make sure that the oil jets are not clogged. If they are

clogged, clean their oil passage using a wire of the

proper size and compressed air.

...

Oil pump inspection

Oil pump inspection

Inspect the oil pump in the following procedures:

remove the oil pump. Refer to “oil pump removal and installation” .

Rotate the oil pump by hand and check that it moves

smoothly. ...

Other materials:

Valve guide replacement

Remove the cylinder head. Refer to “engine top side disassembly” .

Remove the valves. Refer to “cylinder head disassembly and assembly” .

Using the valve guide remover, drive the valve guide

out toward the intake or exhaust camshaft side.

Special tool

(a): 09916–43211 (valve ...

Location of parts

ciutch lever

left handlebar switches

indicator lights

tachometer

ignition switch

front brake fluid reservoir

right handlebar switches

throttle grip

front brake lever

fuel tank cap

front suspension spring pre-load and rebound damping

force ...

Foreword

Motorcycling is one of the most

exhilarating sports and to ensure

your riding enjoyment, you should

become thoroughly familiar with

the information presented in this

owner's manual before riding the

motorcycle.

The proper care and maintenance

that your motorcycle requires is

outlined in t ...