Suzuki GSX-R 1000 Service Manual: Cylinder head disassembly and assembly

Refer to “engine top side disassembly” .

Refer to “engine top side assembly” .

| Caution identify the position of each removed part. Organize the parts in their respective groups (i.E., Intake, exhaust, no. 1 Or no. 2) So that they can be installed in their original locations. |

Disassembly

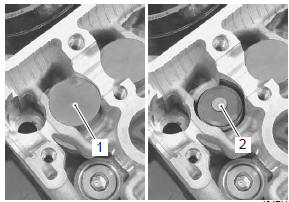

- Remove the tappet (1) and shim (2) by fingers or magnetic hand.

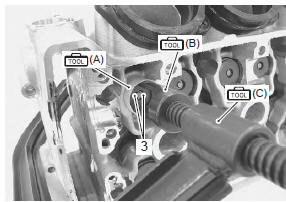

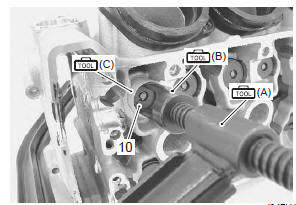

- Insert the special tool (a) between the valve springs and cylinder head.

- Using the special tools, compress the valve springs and remove the two cotter halves (3) from the valve stem.

| Caution be careful not to damage the tappet sliding surface with the special tool. |

Special tool

(a): 09919–28620 (sleeve protector)

(a): 09919–28620 (sleeve protector)

(b): 09916–14522 (valve lifter

(b): 09916–14522 (valve lifter

attachment)

(c): 09916–14510 (valve lifter)

(c): 09916–14510 (valve lifter)

: 09916–84511 (tweezer)

: 09916–84511 (tweezer)

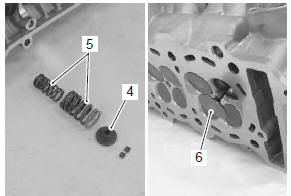

- Remove the valve spring retainer (4) and valve springs (5).

- Pull out the valve (6) from the combustion chamber side.

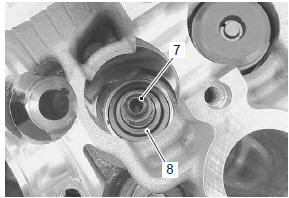

- Remove the oil seal (7) and spring seat (8).

- Remove the other valves in the same manner as described previously.

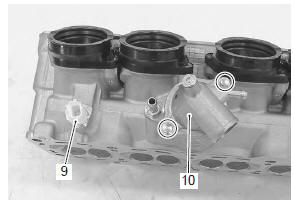

- Remove the ect sensor (9).

- Remove the thermostat cover (10).

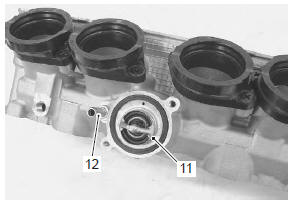

- Remove the thermostat (11).

- Remove the bypass hose union (12).

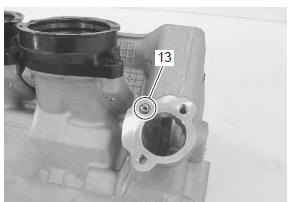

- Remove the oil jet (13).

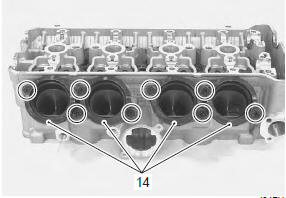

- Remove the intake pipes (14).

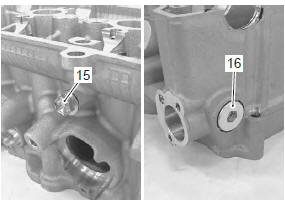

- Remove the oil gallery plug (15).

- Remove the cam chain tension adjuster service cap (16).

Assembly

Assembly is in the reverse order of disassembly. Pay attention to the following points:

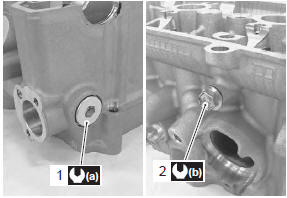

- tighten the cam chain tension adjuster service cap (1) and oil gallery plug (2) to the specified torque.

| Caution replace the gaskets with new ones. |

Tightening torque cam chain tension adjuster service cap (a): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft) oil gallery plug (cylinder head) (b): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Apply grease to o-rings of the intake pipes.

| Caution replace the o-rings with new ones. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

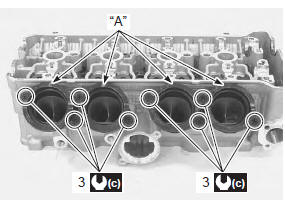

- Install the intake pipes with the up mark “a” facing top side.

- Tighten the intake pipe bolts (3) to the specified torque.

Tightening torque intake pipe bolt (c): 8.5 N·m (0.85 Kgf-m, 6.5 Lbf-ft)

- Apply engine oil to the o-ring and install the oil jet.

| Caution use new o-ring to prevent oil pressure leakage |

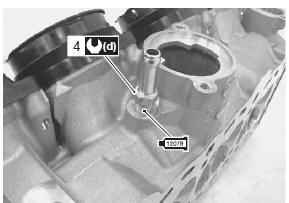

- Apply bond to the thread part of bypass hose union (4) and tighten it to the specified torque.

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

Tightening torque bypass hose union (d): 12 n·m (1.2 Kgf-m, 8.5 Lbfft)

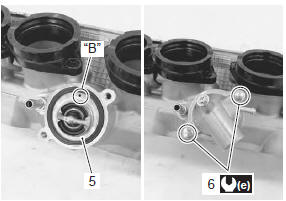

- Install the thermostat (5)

| Note the air bleeder hole “b” of the thermostat faces upside. |

- Tighten the thermostat cover bolts (6) to the specified torque.

Tightening torque thermostat cover bolt (e): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Tighten the ect sensor (7) to the specified torque.

Tightening torque ect sensor (f): 18 n·m (1.8 Kgf-m, 13.0 Lbf-ft)

Caution

|

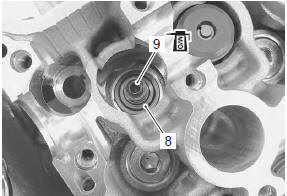

- Install the valve spring seat (8).

- Apply molybdenum oil to the oil seal (9), and press-fit it into the position.

| Caution do not reuse the removed oil seal. |

M/o: molybdenum oil (molybdenum oil solution)

- Insert the valve, with its stem coated with molybdenum oil solution all around and along the full stem length without any break.

| Caution when inserting the valve, take care not to damage the lip of the oil seal. |

M/o: molybdenum oil (molybdenum oil solution)

- Install each valve spring with the small-pitch portion “c” facing cylinder head.

|

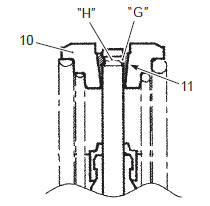

- Put on the valve spring retainer (10), and using the special tools, press down the springs, fit the cotter halves to the stem end, and release the lifter to allow the cotter halves to wedge in between retainer and stem.

Caution

|

Special tool

(a): 09916–14510 (valve lifter)

(a): 09916–14510 (valve lifter)

(b): 09916–14522 (valve lifter

(b): 09916–14522 (valve lifter

attachment)

(c): 09919–28620 (sleeve protector)

(c): 09919–28620 (sleeve protector)

: 09916–84511 (tweezer)

: 09916–84511 (tweezer)

- Be sure that the rounded lip “g” of the cotter fits snugly into the groove “h” in the stem end.

|

- Install the other valves and springs in the same manner as described previously.

- Install the tappet shims and the tappets to their original positions.

Note

|

Cam chain tensioner inspection

Cam chain tensioner inspection

Inspect the cam chain tensioner in the following

procedures:

remove the cam chain tensioner. Refer to “cam chain guide / cam chain

tensioner removal and installation” .

Check the ...

Cylinder head related parts inspection

Cylinder head related parts inspection

Refer to “cylinder head disassembly and assembly” .

Cylinder head distortion

Decarbonize the combustion chambers.

Check the gasket surface of the cylinder head for

distortion. Use a str ...

Other materials:

Specifications

Service data

Brake

unit: mm (in)

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Front brake hose routing diagram” “rear brake hose routing

diagram” “front brake master cylinder components” “rear

...

Wheel balance check and adjustment

Check and adjust the wheel balance in the following

procedures:

removal the wheel assembly. Refer to “front wheel assembly removal and

installation” and “rear wheel assembly removal and installation” .

Remove the mounting drum from the rear wheel.

(For rear wheel) ref ...

Throttle body inspection and cleaning

Refer to “throttle body disassembly and assembly” .

Cleaning

Some

carburetor cleaning chemicals,

especially dip-type soaking solutions, are

very corrosive and must be handled carefully.

Always follow the chemical manufacturer’s

instructions on proper use, handling and

sto ...