Suzuki GSX-R 1000 Service Manual: Engine sprocket removal and installation

Removal

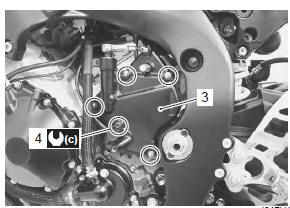

- Remove the gearshift link arm (1) from the gearshift shaft.

| Note mark the gearshift shaft head at which the gearshift link arm slit set for correct reinstallation. |

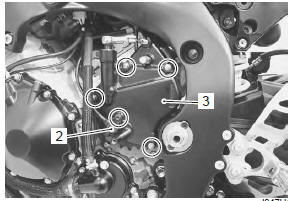

- Remove the speed sensor (2).

- Remove the engine sprocket cover (3).

- Support the motorcycle with a jack or wooden block.

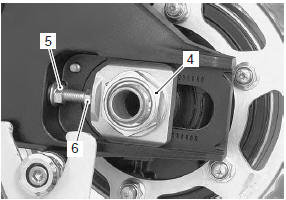

- Loosen the rear axle nut (4) and left and right chain adjuster lock-nuts (5).

- Loosen the chain adjusters (6) to provide additional chain slack.

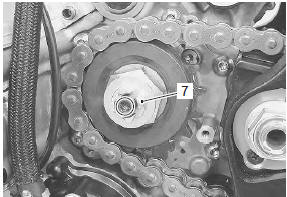

- Remove the speed sensor rotor (7) by removing its bolt while depressing the rear brake pedal.

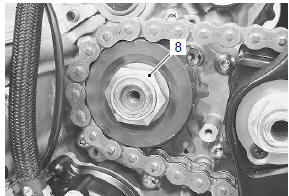

- Remove the engine sprocket nut (8) while depressing the rear brake pedal.

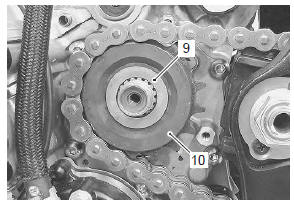

- Remove the washer (9).

- Remove the engine sprocket (10).

Installation

Install the engine sprocket in the reverse order of removal. Pay attention to the following points:

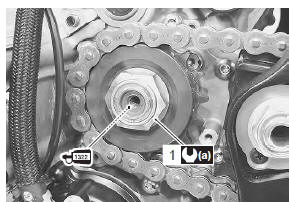

- apply thread lock to the driveshaft.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Tighten the engine sprocket nut (1) to the specified torque.

Tightening torque engine sprocket nut (a): 145 n·m (14.5 Kgf-m, 105.0 Lbf-ft)

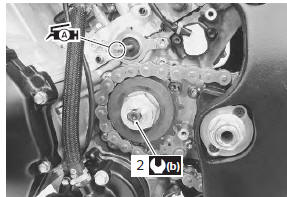

- Tighten the speed sensor rotor bolt (2) to the specified torque.

Tightening torque speed sensor rotor bolt (b): 28 n·m (2.8 Kgf-m, 20.0 Lbf-ft)

- Before installing the engine sprocket cover, apply a small quantity of grease to the clutch push rod.

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the engine sprocket cover (3).

- Tighten the speed sensor mounting bolt (4) to the specified torque.

Tightening torque speed sensor mounting bolt (c): 6.5 N·m (0.65 Kgf-m, 4.5 Lbf-ft)

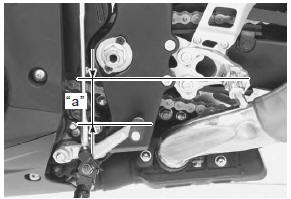

- Fit the gearshift link arm to the gearshift shaft so that the gearshift lever is located at height “a” below the footrest.

Gearshift lever height “a” standard: 65 – 75 mm (2.6 – 3.0 In)

- Adjust the drive chain slack. Refer to “drive chain inspection and adjustment” in section 0b (page 0b- 14).

Drive chain related components

Drive chain related components

Drive chain

Engine sprocket

Rear sprocket

Dust seal

Bearing

Retainer

Sprocket mounting drum

Wheel damper

145 N·m (14.5 Kgf-m,

105.0 Lbf-ft ...

Rear sprocket / rear sprocket mounting drum removal and installation

Rear sprocket / rear sprocket mounting drum removal and installation

Removal

Remove the rear wheel assembly. Refer to “rear wheel assembly removal

and installation” in section 2d .

Loosen the rear sprocket nuts.

Draw out the rear sprocket mountin ...

Other materials:

Rear brake master cylinder components

Reservoir cap

Plate

Diaphragm

Reservoir tank

Reservoir hose

Brake hose

Brake hose union bolt

Brake hose connector

Master cylinder

Spring

Piston/cup set

Push rod

Dust boot

23 N·m (2.3 Kgf-m,

16.5 Lbf-ft)

10 N·m

...

General description

Fuel injection system description

Fuel system

The fuel delivery system consists of the fuel tank (1), fuel pump (2), fuel

filter (3), fuel feed hose (4), fuel delivery pipes

(5) including fuel injectors (6) and (7), fuel pressure regulator (8). There is

no fuel return hose. The fuel in the fu ...

Headlight bulb and position light bulb

replacement

Caution

when you touch the bulb with your bare

hands, clean the bulb with a cloth moistened

with alcohol or soap water to prevent

premature bulb failure.

Low beam bulb

Remove the combination meter. Refer to “combination meter removal and

installation” in section 9c .

...