Suzuki GSX-R 1000 Service Manual: Generator removal and installation

Removal

- Drain engine oil. Refer to “engine oil and filter replacement” in section 0b .

- Remove the left side cowling. Refer to “exterior parts removal and installation” in section 9d .

- Disconnect the generator coupler (1).

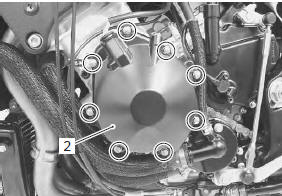

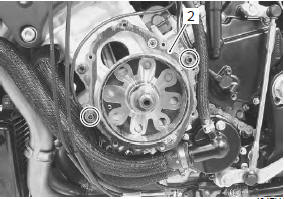

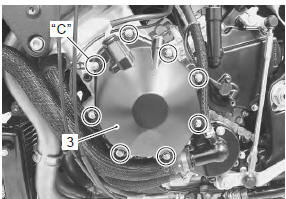

- Remove the generator cover (2).

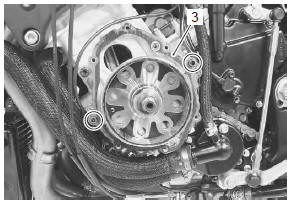

- Remove the gasket (3) and dowel pins.

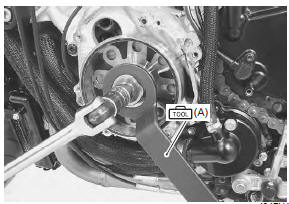

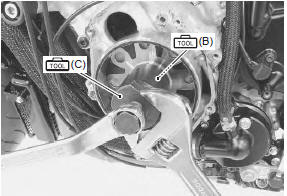

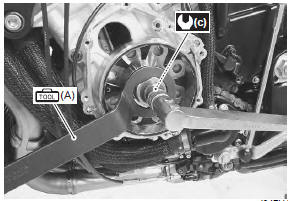

- Hold the generator rotor with the special tool and remove the generator rotor bolt.

Special tool

(a): 09930–44530 (rotor holder)

(a): 09930–44530 (rotor holder)

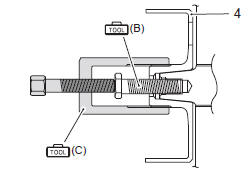

- Screw in the special tool to the crankshaft.

- Remove the generator rotor (4) using the special tool.

Special tool

(b): 09930–30460 (rotor remover

(b): 09930–30460 (rotor remover

bolt)

(c): 09930–34970 (rotor remover)

(c): 09930–34970 (rotor remover)

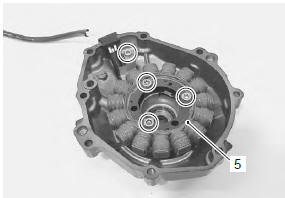

- Remove the generator stator (5).

Installation

Install the generator in the reverse order of removal. Pay attention to the following points:

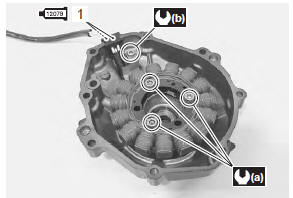

- tighten the generator stator set bolts and generator lead wire set bolt to the specified torque.

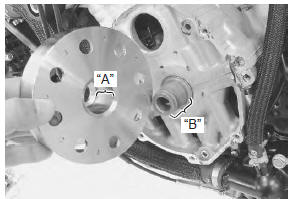

Tightening torque generator stator set bolt (a): 11 n·m (1.1 Kgf-m, 8.0 Lbf-ft) generator lead wire set bolt (b): 5.5 N·m (0.55 Kgfm, 4.0 Lbf-ft)

- Apply bond lightly to the generator lead wire grommet (1).

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

- Degrease the tapered portion “a” of generator rotor and also the crankshaft “b” with nonflammable cleaning solvent.

| Caution dry these parts naturally. Do not wipe them with a cloth or use compressed air to dry. |

- Install the generator rotor onto crankshaft.

- Hold the generator rotor with the special tool and tighten its bolt to the specified torque.

Special tool

(a): 09930–44530 (rotor holder)

(a): 09930–44530 (rotor holder)

Tightening torque generator rotor bolt (c): 145 n·m (14.5 Kgf-m, 105.0 Lbf-ft)

- Apply a bond lightly to the mating surfaces at the parting line between the upper and lower crankcases as shown.

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

- Install the dowel pins and new gasket (2).

| Caution use new gasket to prevent oil leakage. |

- Install the generator cover (3) and tighten the generator cover bolts.

Be careful Be careful

not to pinch the finger between the generator cover and crankcase. |

| Note fit the clamp to the generator cover bolt “c”. |

- Route the generator lead wire. Refer to “wiring harness routing diagram” in section 9a .

Generator inspection

Generator inspection

Generator coil resistance

Remove the left side cowling. Refer to “exterior parts removal and

installation” in section 9d .

Disconnect the generator coupler (1).

Measure the re ...

Regulator / rectifier construction

Regulator / rectifier construction

Regulator/rectifier

Regulator/rectifier bracket

Air intake pipe (rh)

Spacer

Wiring harness

Connect

the regulator/rectifier couplers under the wiring harnes ...

Other materials:

Handlebar removal and installation

Removal

Remove the following parts from the left handlebar.

left handlebar switch box (1)

handlebar balancer (2)

grip rubber (3)

clutch cable (4)

Remove the following parts from the right handlebar.

right handlebar switch box (5)

...

Clutch lifter pin inspection and adjustment

Refer to “clutch removal” and “clutch installation” .

Note

when inspection and adjusting the clutch

lifter pin, it is not necessary to install the

clutch onto the countershaft.

Inspect and adjust the clutch lifter pin in the following

procedures:

assemble the ...

Accessory installation

guideline

Install aerodynamic affecting

accessories, such as a fairing,

windshield, backrests, saddlebags,

and travel trunks, as low

as possible, as close to the

motorcycle and as near the

center of gravity as is feasible.

Check that the mounting

brackets and other attachment

hardware are ...