Suzuki GSX-R 1000 Service Manual: Clutch lifter pin inspection and adjustment

Refer to “clutch removal” and “clutch installation” .

| Note when inspection and adjusting the clutch lifter pin, it is not necessary to install the clutch onto the countershaft. |

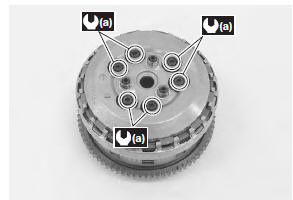

Inspect and adjust the clutch lifter pin in the following procedures:

- assemble the following parts into the primary driven gear assembly.

- Clutch sleeve hub

- spring washer seat, spring washer

- clutch drive plates, clutch driven plates

- pressure plate

- clutch springs, clutch springs set bolts

Tightening torque clutch spring set bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

| Note tighten the clutch spring set bolt little by little and diagonally. |

- Remove the clutch assembly from the primary driven gear assembly.

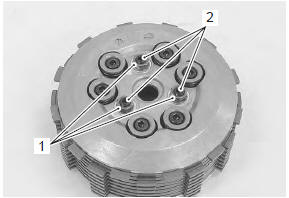

- Inspect the height “a” of clutch lifter pin at three positions using the thickness gauge. If the measurement is out of the specification, adjust the height “a” as shown in the figure.

Special tool

: 09900–20803 (thickness gauge)

: 09900–20803 (thickness gauge)

Clutch lifter pin height “a” standard: 0.2 – 0.4 Mm (0.008 – 0.016 In)

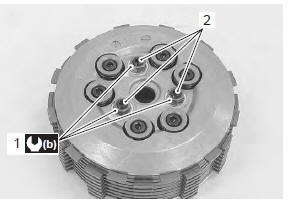

- Loosen the lock-nuts (1) and turn out the clutch lifter pin (2).

| Note each clutch lifter pin height should be as closely as possible. |

- Set the thickness gauge to 0.3 Mm (0.012 In).

Special tool

(a): 09900–20803 (thickness gauge)

(a): 09900–20803 (thickness gauge)

- Place a proper flat plate on the thickness gauges and hold them by hand.

- Slowly turn in the clutch lifter pin (2) until resistance is felt.

- Tighten the lock-nut (1).

Tightening torque clutch lifter pin lock-nut (b): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft)

Clutch parts inspection

Clutch parts inspection

Refer to “clutch removal” and “clutch installation” .

Clutch drive and driven plate

Note

wipe off the engine oil from the drive and

driven plates with a clean rag.

Measure t ...

Specifications

Specifications

Service data

Clutch

unit: mm (in)

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Clutch control system components”&nbs ...

Other materials:

Conclusion

Traffic, road and weather conditions

vary. Other motorists'

actions are unpredictable. Your

motorcycle's condition can

change. These factors can best

be dealt with by giving every ride

your full attention.

Circumstances beyond your control

could lead to an accident. You

need to prepare fo ...

Electrical parts connector / coupler

Faulty fi system is often related to poor electrical

contact of connector/coupler. Before servicing

individual electronic part, check electrical contact of

the connector/coupler.

When connecting a connector, be sure to push it in

until a click is felt.

With a lock type coupler ...

Break-in

The first 800 km (500 miles) is the

most important in the life of your

motorcycle. Proper operation during

this break-in period will help

assure maximum life and performance

from your new motorcycle.

The following guidelines explain

proper break-in procedures.

Maximum engine speed recommen ...