Suzuki GSX-R 1000 Service Manual: Cylinder head cover disassembly and assembly

Disassembly

- Remove the cylinder head cover. Refer to “engine top side disassembly” .

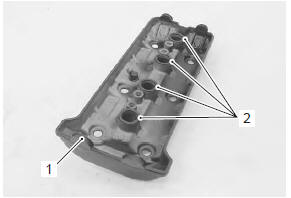

- Remove the gaskets (1) and (2).

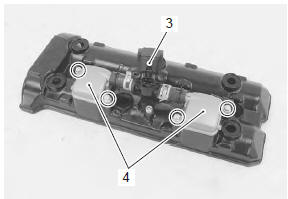

- Remove the pair control solenoid valve (3) along with the pair reed valve covers (4).

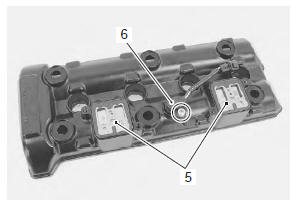

- Remove the pair reed valves (5) and cmp sensor (6).

Assembly

Assembly is in the reverse order of disassembly. Pay attention to the following points:

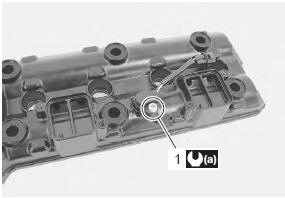

- install the cmp sensor.

| Note when installing the cmp sensor, clean the sensor surface. |

- Tighten the cmp sensor bolt (1) to the specified torque.

Tightening torque cmp sensor bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Install the pair reed valves.

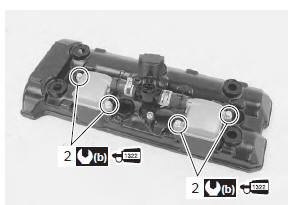

- Apply thread lock to the pair reed valve cover bolts (2) and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque pair reed valve cover bolt (b): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Fit new gaskets and install the cylinder head cover to the cylinder head. Refer to “engine top side assembly” .

Engine top side assembly

Engine top side assembly

Assemble the engine top side in the reverse order of

disassembly. Pay attention to the following points:

Cylinder head

Install the dowel pins and a new cylinder head gasket

(1) to the cylinder ...

Cylinder head cover related parts

inspection

Cylinder head cover related parts

inspection

Refer to “engine top side disassembly” .

Refer to “engine top side assembly” .

Refer to “cylinder head cover disassembly and assembly” .

Cylinder head cover

Clean and check the gasket grooves ...

Other materials:

Using the transmission

The transmission is provided to

keep the engine operating

smoothly in its normal operating

speed range. The gear ratios

have been carefully chosen to

meet the characteristics of the

engine. The rider should always

select the most suitable gear for

the prevailing conditions. Never

slip the c ...

Spark plugs

Your motorcycle comes equipped

with ngk cr9e or denso

u27esr-n spark plugs. To determine

if the standard spark plug is

right for your usage, check the

color of the plug's porcelain center

electrode insulator after motorcycle

operation. A light brown

color indicates that the plug is correct.

...

Special tools and equipment

Recommended service material

Note

required service material is also described in the following.

“Front fork components”

Special tool

...