Suzuki GSX-R 1000 Service Manual: DTC “c12” (p0335): ckp sensor circuit malfunction.

Detected condition and possible cause

|

Detected condition |

Possible cause |

| The signal does not reach ecm for 3 sec. Or more, after receiving the starter signal. |

|

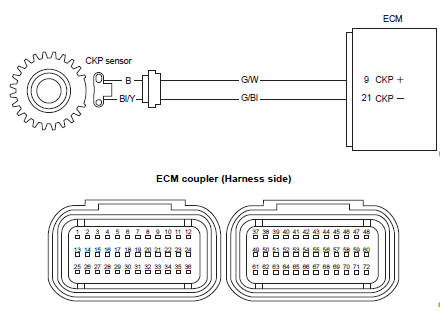

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

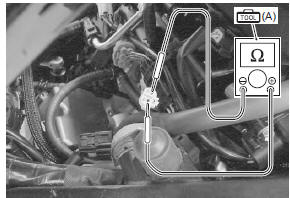

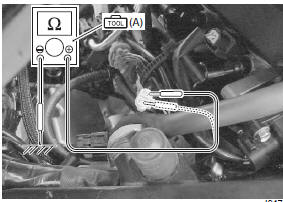

1 |

Special tool (a): 09900–25008 (multi circuit tester set) Tester knob indication resistance (Ω) Ckp sensor resistance 142 – 194 Ω (b – bl/y)

Special tool

Ckp sensor continuity ∞Ω¶ (infinity) (b . Ground, bl/y. Ground)

Are the resistance and continuity ok? |

Go to step 2. | Replace the ckp sensor with a new one. |

|

2 |

Special tool

Tester knob indication

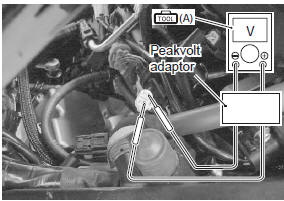

voltage ( Ckp sensor peak voltage 0.5 V and more ((+) terminal: b – (–) terminal: bl/y)

Is the voltage ok? |

|

|

DTC “c11” (p0340): cmp sensor circuit

malfunction

DTC “c11” (p0340): cmp sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

The signal does not reach ecm for 3 sec. Or more, after

receiving the starter signal.

...

DTC “c13” (p0105-h/l): iap sensor circuit

malfunction

DTC “c13” (p0105-h/l): iap sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C13

Iap sensor voltage is not within the

following range.

0.5 V ≤ Sensor voltage &l ...

Other materials:

Stv actuator removal and installation

Refer to “throttle body disassembly and assembly” in section 1d .

Caution

never remove the stva from the throttle

body.

Isc valve inspection

Refer to “dtc “c40” (p0505 / p0506 / p0507): isc valve circuit malfunction”

in section 1a .

Isc valve removal and installation

Refer t ...

Battery removal and installation

Removal

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the battery (–) lead wire (1).

Disconnect the battery (+) lead wire (2).

Note

be sure to disconnect the battery (–) lead

wire (1) first, th ...

Exterior parts construction

Upper cowling bracket

: set the punch mark to the front and upper side.

Rear view mirror cushion

: set the dent side to inside.

To frame

To headlight assembly

To sprocket cove

To side-stand bracket

...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)