Suzuki GSX-R 1000 Service Manual: Gearshift shaft / gearshift cam plate removal and installation

Removal

- Remove the engine sprocket cover. Refer to “engine sprocket removal and installation” in section 3a .

- Remove the clutch components. Refer to “clutch removal” in section 5c .

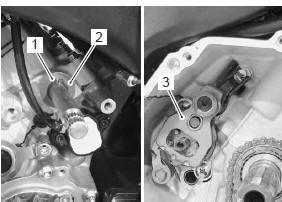

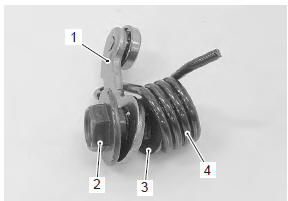

- Remove the snap ring (1) and washer (2) from the gearshift shaft.

Special tool

: 09900–06107 (snap ring remover

: 09900–06107 (snap ring remover

(open

type))

- Remove the gearshift shaft assembly (3).

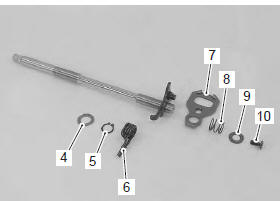

- Remove the following parts from the gearshift shaft.

Special tool

: 09900–06107 (snap ring remover

: 09900–06107 (snap ring remover

(open

type))

|

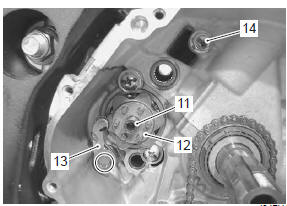

- Remove the gearshift cam plate bolt (11) and gearshift cam plate (12).

- Remove the gearshift cam stopper (13).

- Remove the gearshift arm stopper (14).

Installation

Install the gearshift shaft and gearshift cam plate in the reverse order of removal. Pay attention to the following points:

| Caution the removed snap rings must be replaced with new ones. |

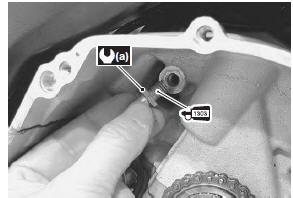

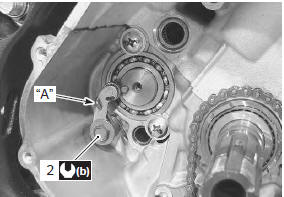

- Apply a small quantity of thread lock to the gearshift arm stopper and tighten it to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32030

(thread lock cement super “1303” or

equivalent)

Tightening torque gearshift arm stopper (a): 19 n·m (1.9 Kgf-m, 13.5 Lbf-ft)

- Assemble the gearshift cam stopper (1), bolt (2), washer (3) and return spring (4).

- Tighten the gearshift cam stopper bolt (2) to the specified torque.

| Note hook the return spring end “a” to the stopper. |

Tightening torque gearshift cam stopper bolt (b): 10 n·m (1.0 Kgfm, 7.0 Lbf-ft)

- Check the gearshift cam stopper moves smoothly.

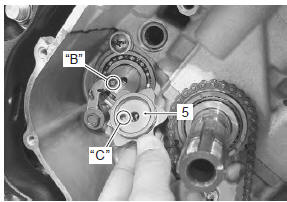

- Locate the gearshift cam in the neutral position.

- Install the gearshift cam plate (5).

| Note align the gearshift cam pin “b” with the gearshift cam plate hole “c”. |

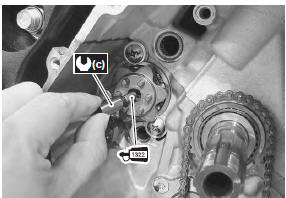

- Apply a small quantity of thread lock to the gearshift cam plate bolt and tighten it to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque gearshift cam plate bolt (c): 13 n·m (1.3 Kgf-m, 9.5 Lbf-ft)

- Apply a small quantity of thread lock to the gearshift shaft end screw and tighten it to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque gearshift shaft end screw (d): 8.5 N·m (0.85 Kgfm, 6.0 Lbf-ft)

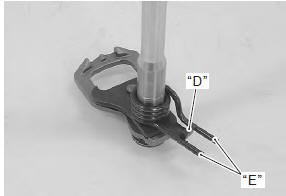

- When installing the gearshift shaft return spring, position the stopper “d” of gearshift arm between the shaft return spring ends “e”.

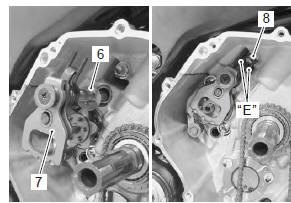

- Install the washer (6) and gearshift shaft assembly (7).

| Note pinch the gearshift arm stopper (8) with return spring ends “e”. |

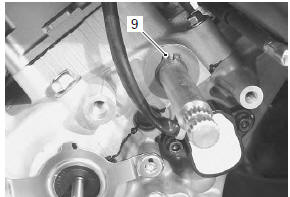

- Install a new snap ring (9).

Special tool

: 09900–06107 (snap ring remover

: 09900–06107 (snap ring remover

(open

type))

- After installing the gearshift lever, check the gearshift lever height. Refer to “gearshift lever height inspection and adjustment” .

Gearshift shaft construction

Gearshift shaft construction

Gearshift shaft

Washer

Snap ring

Gearshift shaft return spring

Gearshift cam drive plate

Gearshift plate return spring

8.5 N·m (0.85 Kgf-m,

6.0 Lb ...

Gearshift linkage inspection

Gearshift linkage inspection

Refer to “gearshift shaft / gearshift cam plate removal and installation” .

Gearshift shaft

Check the gearshift shaft for bend or wear.

Check the return spring for damage or fatigue.

If any de ...

Other materials:

Steering / steering damper removal and

installation

Removal

steering damper

Turn the ignition switch off.

Disconnect the steering damper solenoid coupler

(1).

Remove the lower bracket cover (2).

Remove the steering damper mounting nut (3) while

holding the lock-nut (4).

Remove the steering damper mounting bolt ( ...

Special tools and equipment

Recommended service material

Note

required service material is also described in the following.

“Front fork components”

Special tool

...

Self-diagnostic procedures

Use of mode select switch

Note

do not disconnect the coupler from ecm,

battery cable from battery, ecm ground

wire from engine or main fuse before

confirming dtc (diagnostic trouble code)

stored in memory. Such disconnection

may erase memorized information in ec ...