Suzuki GSX-R 1000 Service Manual: DTC “c28” (p1655): secondary throttle valve actuator (stva) malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

| The operation voltage does not reach the stva. Ecm does not receive communication signal from the stva. Stva can not operate properly or its motor locked |

|

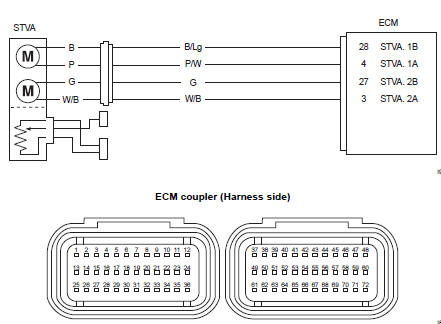

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

1 |

Is the operation ok? |

Go to step 2. |

|

| 2 |

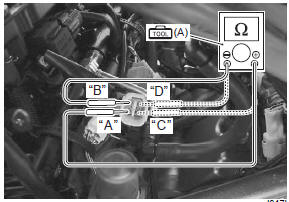

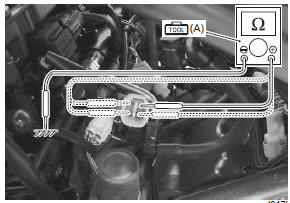

Special tool (a): 09900–25008 (multi circuit tester set) Tester knob indication resistance (Ω) Stva continuity ∞Ω¶ (infinity) (terminal . Ground)

Special tool

Stva resistance approx. 6.5 Ω (terminal “a” – terminal “b”, terminal “c” – terminal “d”)

|

|

|

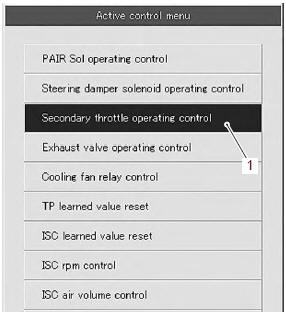

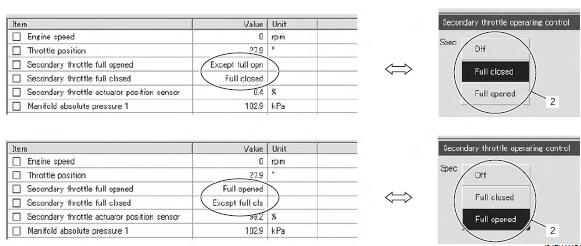

Active control inspection

- Set up the sds tool. (Refer to the sds operation manual for further details.)

- Turn the ignition switch on.

- Click “secondary throttle operating control” (1).

- Click each button (2).

At this time, if an operation sound is heard from the stva, the function is normal.

DTC “c23” (p1651-h/l): to sensor circuit

malfunction

DTC “c23” (p1651-h/l): to sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C23

The sensor voltage should be the

following for 2 sec. And more, after ignition

switch i ...

DTC “c29” (p1654-h/l): secondary throttle

position sensor (stps) circuit malfunction

DTC “c29” (p1654-h/l): secondary throttle

position sensor (stps) circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

C29

Output voltage is not within the following

range.

Difference between actual throttle op ...

Other materials:

Cylinder head cover related parts

inspection

Refer to “engine top side disassembly” .

Refer to “engine top side assembly” .

Refer to “cylinder head cover disassembly and assembly” .

Cylinder head cover

Clean and check the gasket grooves “a” and pair reed

valve mating surfaces “b” of the cylinder head cover.

If there is anything unu ...

Ignition switch removal and installation

Removal

Remove the air cleaner box. Refer to “air cleaner box removal and

installation” in section 1d .

Disconnect the ignition switch lead wire coupler (1).

Disconnect the immobilizer lead wire coupler (2).

(For e-02, 19, 24, 51)

Remove the harness clamp (3).

...

Engine oil

Oil quality is a major contributor to

your engine's performance and

life. Always select good quality

engine oil. Suzuki recommends

the use of suzuki performance

4 motor oil or equivalent

engine oil. Use sf/sg or sh/

sj with jaso ma in api (american

petroleum institute) classification.

A ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi