Suzuki GSX-R 1000 Service Manual: Heated oxygen sensor (ho2s) removal and installation

Removal

Do not Do not

remove the ho2 sensor while it is hot. |

Caution

|

- Lift and support the fuel tank with the prop stay.

Refer to “fuel tank removal and installation” in section 1g .

- Disconnect the ho2 sensor coupler (1).

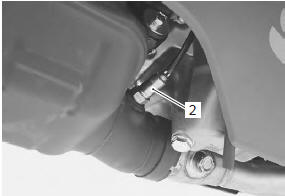

- Remove the ho2 sensor (2).

Installation

Install the ho2 sensor in the reverse order of removal.

Pay attention to the following points:

| Caution do not apply oil or other materials to the sensor air hole. |

- Tighten the ho2 sensor to the specified torque.

Tightening torque ho2 sensor (a): 25 n·m (2.5 Kgf-m, 18.0 Lbf-ft)

Heated oxygen sensor (ho2s) inspection

Refer to “dtc “c44” (p0130/p0135): ho2 sensor (ho2s) circuit malfunction” in section 1a (page 1a- 103).

Pair reed valve removal and installation

Pair reed valve removal and installation

Removal

Lift and support the fuel tank with the prop stay.

Refer to “fuel tank removal and installation” in section 1g .

Remove the air cleaner box. Refer to “air cleaner box removal and ...

Other materials:

Drive mode selector inspection

Inspect the drive mode selector in the following procedures:

set up the sds tool. (Refer to the sds operation manual for

further details.)

Turn the ignition switch on.

Click “data monitor”.

Make sure each of “driving mode selection” on the monitor is

indicated ...

DTC “c14” (p0120-h/l): tp sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C14

Output voltage is not within the following

range.

Difference between actual throttle opening

and opening calculated by ecm is larger

than specified value.

0.2 V ≤ Sensor ...

Using the transmission

The transmission is provided to

keep the engine operating

smoothly in its normal operating

speed range. The gear ratios

have been carefully chosen to

meet the characteristics of the

engine. The rider should always

select the most suitable gear for

the prevailing conditions. Never

slip the c ...