Suzuki GSX-R 1000 Service Manual: Pair reed valve removal and installation

Removal

- Lift and support the fuel tank with the prop stay.

Refer to “fuel tank removal and installation” in section 1g .

- Remove the air cleaner box. Refer to “air cleaner box removal and installation” in section 1d .

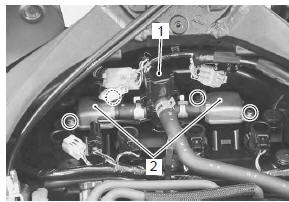

- Remove the pair control solenoid valve (1) along with the pair reed valve covers (2). Refer to “pair control solenoid valve removal and installation” .

- Remove the pair reed valves (3).

Installation

Install the pair reed valve in the reverse order of removal. Pay attention to the following points:

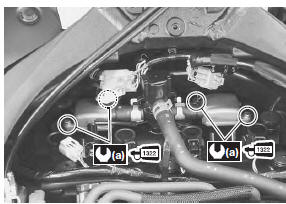

- apply thread lock to the pair reed valve cover bolts and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque pair reed valve cover bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

Heated oxygen sensor (ho2s) removal and

installation

Heated oxygen sensor (ho2s) removal and

installation

Removal

Do not

remove the ho2 sensor while it is hot.

Caution

be careful not to expose the ho2 sensor to

excessive shock.

Do not use an impact ...

Pair control solenoid valve removal and

installation

Pair control solenoid valve removal and

installation

Removal

Lift and support the fuel tank with the prop stay.

Refer to “fuel tank removal and installation” in section 1g .

Remove the air cleaner box. Refer to “air cleaner box removal and ...

Other materials:

Swingarm bearing removal and installation

Removal

Remove the swingarm. Refer to “swingarm removal and installation” .

Remove the swingarm pivot bearings (1) using the

special tool.

Special tool

(a):

09921–20240 (bearing remover set)

Remove the center spacer (2).

Remove the cushion lever bearing (3) usin ...

Engine oil and filter replacement

Replace engine oil

initially at 1 000 km (600 miles, 2 months) and every

6 000 km (4 000 miles, 12 months) thereafter

Replace oil filter

initially at 1 000 km (600 miles, 2 months) and every

18 000 km (11 000 miles, 36 months) thereafter

Oil should be changed while the engine is warm. Oil filt ...

Wiring harness routing diagram

Wiring harness no. 2

Tapping clamp

: insert the clamp from the front side. Place the turn signal

and position light couplers in front of the clamp.

Steel clamp

: clamp the wiring harness at the blue taping point. Bend

the steel clamps to the front side.

...