Suzuki GSX-R 1000 Service Manual: Rear shock absorber bearing removal and installation

Removal

- Remove the rear shock absorber. Refer to “rear shock absorber removal and installation” .

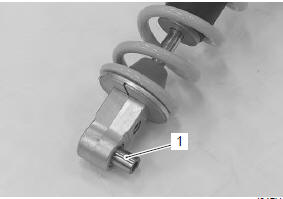

- Remove the spacer (1).

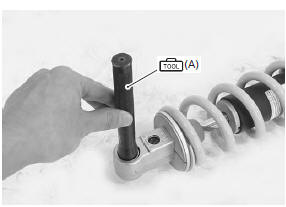

- Remove the rear shock absorber bearing with the special tool.

Special tool

(a): 09943–88211 (pinion bearing

(a): 09943–88211 (pinion bearing

installer)

Installation

| Caution the removed bearing must be replaced with a new one. |

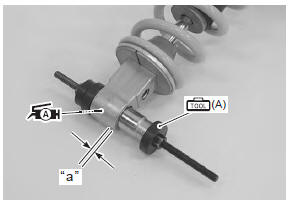

- Press the bearing into the rear shock absorber at 0.5 Mm (0.02 In) depth “a” from the rear shock absorber side surface with the special tool and suitable size socket wrench.

| Note apply a small quantity of the grease to housing when installing the bearing. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

Special tool

(a): 09924–84521 (bearing installer

(a): 09924–84521 (bearing installer

set)

|

- Apply grease to the bearing.

: Grease 99000–25010 (suzuki super grease “a” or equivalent)

- Install the rear shock absorber. Refer to “rear shock absorber removal and installation” .

Rear shock absorber inspection

Rear shock absorber inspection

Refer to “rear shock absorber removal and installation” .

Shock absorber

Inspect the rear shock absorber for damage and oil

leakage, and absorber bushing for wear and damage. If

any defect is foun ...

Rear shock absorber adjustment

Rear shock absorber adjustment

After installing the rear suspension, adjust the spring

pre-load and damping force as follows:

Spring pre-load adjustment

The set length 179.3 Mm (7.06 In) provides the

maximum spring pre-load ...

Other materials:

Brake fluid

Check the brake fluid level in both front and rear brake fluid reservoirs. If

the level in either reservoir is below the lower mark, inspect for brake pad

wear and leaks.

Warning

Brake fluid is harmful or fatal if

swallowed, and harmful if it

comes in contact with skin or

...

Fuses

The main fuse is located under

the front seat. To access the fuse,

remove the seat by referring to

the seat lock and helmet

holders.

The fuses are located inside the

left fairing. One 1 oa and one 15a

spare fuses are provided inside

the fuse box.

They are designed to open when ...

Gearshift lever height inspection and

adjustment

Inspect and adjust the gearshift lever height in the

following procedures:

inspect the gearshift lever height “a” between the

lever top and footrest.

Adjust the gearshift lever height if necessary.

Gearshift lever height “a”

standard: 65 – 75 mm (2.6 – 3.0 In)

Loosen the l ...