Suzuki GSX-R 1000 Service Manual: Rear wheel related parts inspection

Refer to “rear wheel assembly removal and installation” .

Tire

Refer to “tire inspection” in section 0b .

Rear brake disc

Refer to “rear brake disc inspection” in section 4c .

Wheel damper

Refer to “drive chain related parts inspection” in section 3a .

Sprocket

Refer to “drive chain related components” in section 3a .

Dust seal

Inspect the dust seal lip for wear or damage. If any defects is found, replace the dust seal with a new one.

Refer to “rear wheel dust seal / bearing removal and installation” .

Wheel axle

Using a dial gauge, check the wheel axle for runout, if the runout exceeds the limit, replace the axle shaft.

Wheel axle runout service limit: 0.25 Mm (0.010 In)

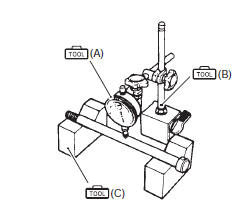

Special tool

(a): 09900–20607 (dial gauge)

(a): 09900–20607 (dial gauge)

(b): 09900–20701 (dial gauge

(b): 09900–20701 (dial gauge

chuck)

(c): 09900–21304 (v blocks)

(c): 09900–21304 (v blocks)

Wheel

- Remove the rear brake pads. Refer to “rear brake pad replacement” in section 4c .

- Make sure that the wheel runout checked as shown in the figure does not exceed the service limit. An excessive runout is usually due to worn or loosened wheel bearings and can be reduced by replacing the bearings. If bearing replacement fails to reduce the runout, replace the wheel.

Wheel rim runout service limit (axial and radial): 2.0 Mm (0.08 In)

- Install the rear brake pads. Refer to “rear brake pad replacement” in section 4c .

Bearing

Inspect the play of the wheel bearings by hand while they are in the wheel. Rotate the inner race by hand to inspect for abnormal noise and smooth rotation. Replace the bearing if there is anything unusual. Refer to “rear wheel dust seal / bearing removal and installation” .

Rear wheel assembly removal and installation

Rear wheel assembly removal and installation

Removal

Loosen the axle nut (1).

Raise the rear wheel off the ground and support the

motorcycle with a jack or wooden block.

Caution

make sure that the motorcycle is support ...

Rear wheel dust seal / bearing removal and installation

Rear wheel dust seal / bearing removal and installation

Removal

Remove the rear wheel assembly. Refer to “rear wheel assembly removal

and installation” .

Remove the rear sprocket mounting drum assembly

(1) from the rear wheel.

Re ...

Other materials:

Precautions

Precautions for brake system

Refer to “general precautions” in section 00 (page 00-1).

Brake fluid information

This brake system is filled with an ethylene glycol-based dot 4

brake fluid. Do not use or mix

different types of fluid, such as silicone-based or petroleum-based.

...

Precautions

Precautions for engine electrical device

Refer to “general precautions” in section 00 (page 00-1) and “precautions for

electrical circuit service” in section 00

(page 00-2).

Component location

Engine electrical components location

Refer to “electrical components location” in section 0a .

Dia ...

Front brake components

Seal set

Piston and seal set

Brake pad spring

Brake pad set

Front brake disc

7.5

N·m (0.75 Kgf-m, 5.5 Lbf-ft)

15 N·m (1.5

Kgf-m, 11.0 Lbf-ft)

39 N·m (3.9

Kgf-m, 28.0 Lbf-ft)

18 N·m (1.8

Kgf-m, 13.0 Lbf-ft)

Apply thread lo ...