Suzuki GSX-R 1000 Service Manual: Throttle valve synchronization

Check and adjust the throttle valve synchronization among four cylinders.

- Start the engine and run it in idling condition for warming up.

- Stop the warmed-up engine.

- Lift and support the fuel tank. Refer to “fuel tank removal and installation” in section 1g (page 1g- 9).

- Remove the clamps (1).

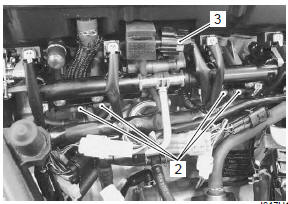

- Disconnect the respective vacuum hoses (2) from vacuum nipples on the throttle body.

- Disconnect the iap sensor coupler (3).

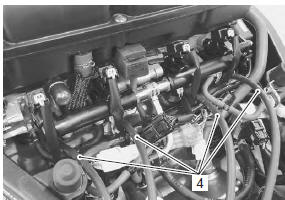

- Connect the respective vacuum tester hoses (4) to the vacuum nipples.

- Set up the sds tool. (Refer to the sds operation manual for further details.)

- Start the engine.

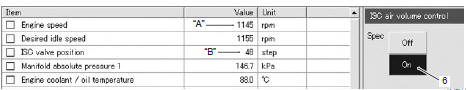

- Click “data monitor”.

- Warm up the engine (engine coolant temp. More than 80 °c (176 °f)).

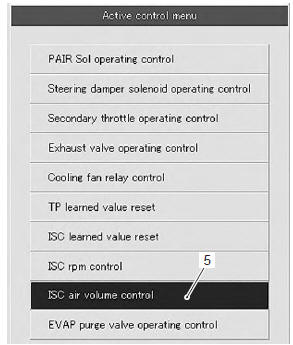

- Click “active control”.

- Click “isc air volume control” (5).

- Click “on” button (6) to fix the isc air volume of four cylinders.

| Note when making this synchronization, be sure that the engine coolant temperature is within 80 – 100 °c (176 – 212 °f). |

|

- Check for the synchronization of vacuum from #1 to #4 cylinders.

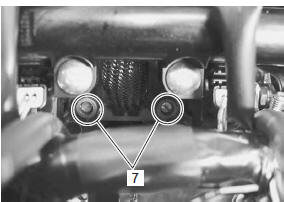

- Equalize the vacuum of the cylinders by turning each air screw (7) and keep it running at idling speed.

| Note always set the engine rpm at idle rpm. |

- If the adjustment is not yet correct, remove each air screw and clean them with a spray-type carburetor cleaner and blow dry with a compressed air. Also, clean the air screw passageways.

Note

|

- Repeat the procedures from 9) to 16).

- Close the sds tool and turn the ignition switch off.

- Disconnect the vacuum tester and reinstall the removed parts.

- After completing the throttle valve synchronization, clear the dtc and reset the isc learned value using sds tool. Refer to “isc valve preset and opening initialization” in section 1c .

Isc valve visual inspection

Isc valve visual inspection

Visually inspect the isc valve if necessary.

Inspect the isc valve for any carbon deposition

defects. Clean or replace the isc valve if necessary.

...

Isc valve reset

Isc valve reset

When removing or replacing the throttle body assembly,

reset the isc valve learned value in the following

procedures:

turn the ignition switch on position.

Set up the sds tools. (Refer t ...

Other materials:

General description

Fuel injection system description

Fuel system

The fuel delivery system consists of the fuel tank (1), fuel pump (2), fuel

filter (3), fuel feed hose (4), fuel delivery pipes

(5) including fuel injectors (6) and (7), fuel pressure regulator (8). There is

no fuel return hose. The fuel in the fu ...

Specifications

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Body frame construction” “front footrest bracket construction”

“side-stand construction”

Reference: for the tightening torque of fastener not specified in this ...

Diagnostic information and procedures

Drive chain and sprocket symptom diagnosis

Condition

Possible cause

Correction / reference item

Noisy drive chain

Worn sprocket

Replace

Worn drive chain

Replace

Stretched drive chain

Replace

Too large drive chain slack

Adju ...