Suzuki GSX-R 1000 Service Manual: Short circuit check (wire harness to ground)

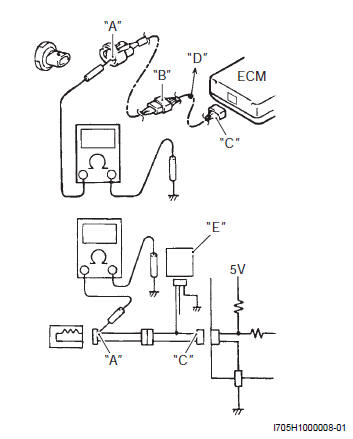

- Disconnect the negative (–) cable from the battery.

- Disconnect the connectors/couplers at both ends of the circuit to be checked.

| Note if the circuit to be checked branches to other parts as shown, disconnect all connectors/ couplers of those parts. Otherwise, diagnosis will be wrong. |

- Measure resistance between terminal at one end of circuit (“a” terminal in figure) and body ground. If continuity is indicated, there is a short circuit to ground between terminals “a” and “c”.

|

- Disconnect the connector/coupler included in circuit (coupler “b”) and measure resistance between terminal “a” and body ground. If continuity is indicated, the circuit is shorted to ground between terminals “a” and “b”.

|

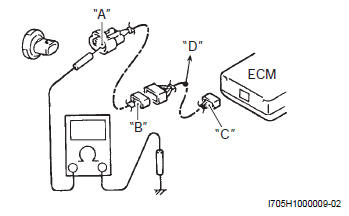

Voltage check

Voltage check

If voltage is supplied to the circuit being checked, voltage

check can be used as circuit check.

With all connectors/couplers connected and voltage

applied to the circuit being checked, m ...

Using the multi-circuit testers

Using the multi-circuit testers

Use the suzuki multi-circuit tester set.

Use well-charged batteries in the tester.

Be sure to set the tester to the correct testing range.

Special tool

(A): 09900–25008

(multi ...

Other materials:

Diagnostic information and procedures

Drive chain and sprocket symptom diagnosis

Condition

Possible cause

Correction / reference item

Noisy drive chain

Worn sprocket

Replace

Worn drive chain

Replace

Stretched drive chain

Replace

Too large drive chain slack

Adju ...

Tires

Warning

Failure to follow these warnings

may result in an accident

due to tire failure. The tires on

your motorcycle form the crucial

link between your motorcycle

and the road.

Follow these instructions:

check tire condition and

pressure, and adjust pres ...

Front brake hose removal and installation

Removal

Drain brake fluid. Refer to “brake fluid replacement” .

2) Remove the front brake hoses as shown in the front brake hose routing

diagram. Refer to “front brake hose routing diagram” .

Installation

Caution

the seal washers should be replaced with the

new ones to pr ...