Suzuki GSX-R 1000 Service Manual: Show data when trouble (displaying data at the time of DTC)

Use of sds

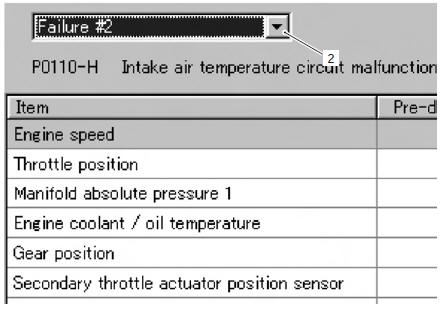

Ecm stores the engine and driving conditions (in the form of data as shown in the figure) at the moment of the detection of a malfunction in its memory. This data is called “show data when trouble”.

Therefore, it is possible to know engine and driving conditions (e.G., Whether the engine was warm or not, where the motorcycle was running or stopped) when a malfunction was detected by checking the show data when trouble. This show data when trouble function can record the maximum of two diagnostic trouble codes in the ecm.

Also, ecm has a function to store each show data when trouble for two different malfunctions in the order of occurrence as the malfunction is detected. Utilizing this function, it is possible to know the order of malfunctions that have been detected. Its use is helpful when rechecking or diagnosing a trouble.

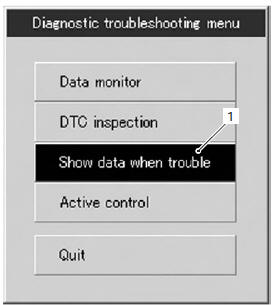

- Click “show data when trouble” (1) to display the data.

- Click the drop down button (2), either “failure #1” or “failure #2” can be selected.

Use of sds diagnosis reset procedures

Use of sds diagnosis reset procedures

Note

the malfunction code is memorized in the

ecm also when the lead wire coupler of any

sensor is disconnected. Therefore, when a

lead wire coupler has been disconnected at

the ...

Sds check

Sds check

Using sds, sample the data at the time of new and periodic vehicle

inspections.

After saving the sampled data in the computer, file them by model and by user.

The periodically filed data help ...

Other materials:

Fuel mesh filter inspection and cleaning

Inspect the fuel mesh filter in the following procedures:

remove the fuel mesh filter. Refer to “fuel pump disassembly and

assembly” .

If the fuel mesh filter is clogged with foreign particles,

it hinders smooth gasoline flow resulting in loss of

engine power. Such a filter ...

General precautions

Proper service and repair procedures are

important for the safety of the service

mechanic and the safety and reliability of

the motorcycle.

When 2 or more persons work together,

pay attention to the safety of each other.

When it is necessary to run the ...

Specifications

Service data

Suspension

unit: mm (in)

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Rear suspension components” “rear suspension assembly

construction”

Reference: for the tightening torque of fastener ...