Suzuki GSX-R 1000 Service Manual: Water pump disassembly and assembly

Refer to “water pump removal and installation” .

Disassembly

- Remove the air bleeder bolt (1) if necessary.

- Remove the water pump case screws.

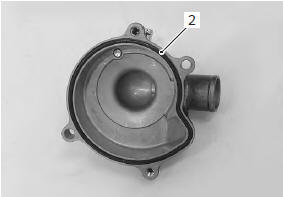

- Remove the o-ring (2).

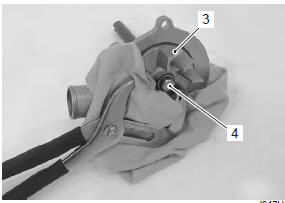

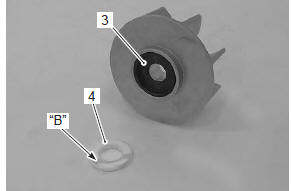

- Hold the impeller (3) with water pump pliers and remove the impeller securing bolt (4).

- Remove the impeller (3).

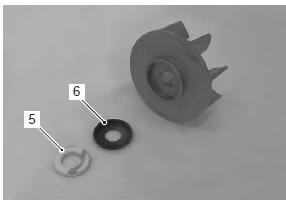

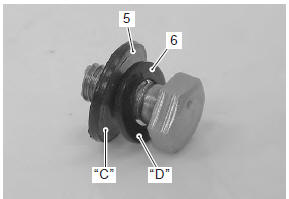

- Remove the mechanical seal ring (5) and rubber seal (6) from the impeller.

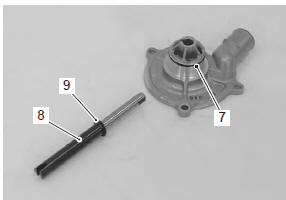

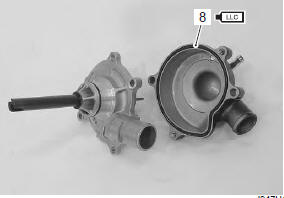

- Remove the o-ring (7), impeller shaft (8) and washer (9) from the holder.

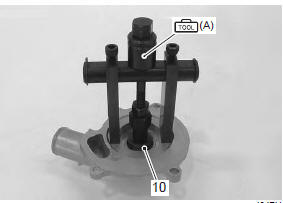

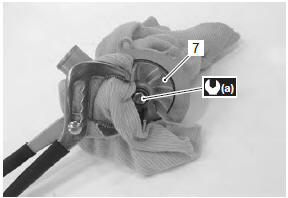

- Remove the mechanical seal (10) with the special tool.

| Note if there is no abnormal condition, the mechanical seal removal is not necessary. |

Special tool

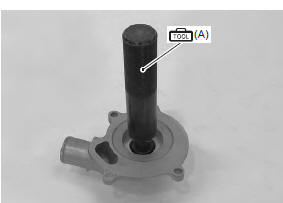

(a): 09921–20240 (bearing remover

(a): 09921–20240 (bearing remover

set)

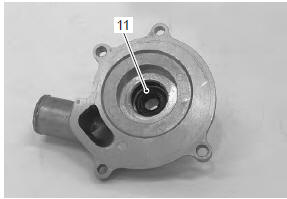

- Remove the oil seal (11).

| Note if there is no abnormal condition, the oil seal removal is not necessary. |

Assembly

- Install the oil seal with the special tool.

| Caution the removed oil seal must be replaced with a new one. |

| Note the stamped mark on the oil seal should face mechanical seal side. |

Special tool

(a): 09913–70210 (bearing

(a): 09913–70210 (bearing

installing set (10

– 75 ö))

- Apply a small quantity of the grease to the oil seal lip.

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install a new mechanical seal using a suitable size socket wrench.

| Caution the removed mechanical seal must be replaced with a new one. |

| Note on new mechanical seals, the sealer “a” has been applied. |

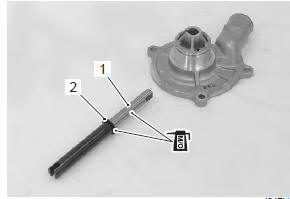

- Apply molybdenum solution to the impeller shaft (1) and washer (2).

M/o: molybdenum oil (molybdenum oil solution)

- Install the impeller shaft (1) and washer (2) to the holder.

- Install the rubber seal (3) into the impeller.

- After wiping off the oily or greasy matter from the mechanical seal ring (4), install it into the impeller.

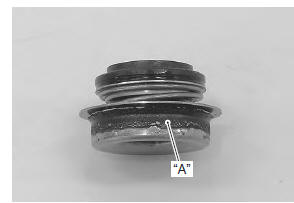

| Note the paint marked side “b” of mechanical seal ring faces the rubber seal. |

- Install the washer (5) and seal washer (6) onto the impeller securing bolt.

| Note the metal side “c” of seal washer and the curved side “d” of washer face the impeller securing bolt head. |

- Install the impeller (7).

- Hold the impeller with water pump pliers and tighten the impeller securing bolt to the specified torque.

Tightening torque impeller securing bolt (a): 8 n·m (0.8 Kgf-m, 6.0 Lbf-ft)

- Install new o-ring (8) and apply engine coolant to it.

| Caution use a new o-ring to prevent engine coolant leakage. |

- Tighten the water pump case screws to the specified torque.

Tightening torque water pump case screw: 6 n·m (0.6 Kgf-m, 4.5 Lbf-ft)

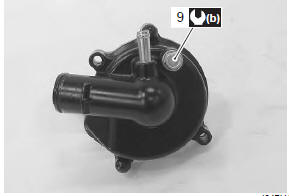

- Tighten the water pump air bleeder bolt (9) to the specified torque.

| Caution use a new gasket washer to prevent engine coolant leakage. |

Tightening torque water pump air bleeder bolt (b): 13 n·m (1.3 Kgfm, 9.5 Lbf-ft)

Water pump removal and installation

Water pump removal and installation

Removal

Note

before draining engine oil and engine coolant, inspect engine oil and

coolant leakage between the water pump and crankcase. If engine oil is

leaking, visually inspect t ...

Water pump related parts inspection

Water pump related parts inspection

Refer to “water pump disassembly and assembly” .

Mechanical seal

Visually inspect the mechanical seal for damage, with

particular attention given to the sealing face.

Replace the mechanical seal ...

Other materials:

Rod guide case tightening torque

Tighten the rod guide case in the following procedures:

measure the effective length l of the torque wrench.

Calculate the reading torque on the torque wrench by

use of the formula shown below.

Special tool

(a): 09940–84710 (rod guide case

wrench)

T: reading torque on the torq ...

Specifications

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Handlebar components” “steering components” “steering

damper construction”

Reference: for the tightening torque of fastener not specified in this

section ...

Special tools and equipment

Recommended service material

Note

required service material is also described in the following.

“Water hose routing diagram” “water pump components” “water

pump construction”

Special tool

...