Suzuki GSX-R 1000 Service Manual: Clutch lifter pin inspection and adjustment

Refer to “clutch removal” and “clutch installation” .

| Note when inspection and adjusting the clutch lifter pin, it is not necessary to install the clutch onto the countershaft. |

Inspect and adjust the clutch lifter pin in the following procedures:

- assemble the following parts into the primary driven gear assembly.

- Clutch sleeve hub

- spring washer seat, spring washer

- clutch drive plates, clutch driven plates

- pressure plate

- clutch springs, clutch springs set bolts

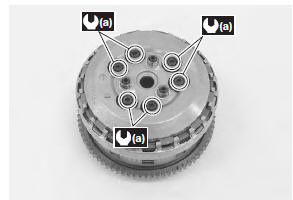

Tightening torque clutch spring set bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

| Note tighten the clutch spring set bolt little by little and diagonally. |

- Remove the clutch assembly from the primary driven gear assembly.

- Inspect the height “a” of clutch lifter pin at three positions using the thickness gauge. If the measurement is out of the specification, adjust the height “a” as shown in the figure.

Special tool

: 09900–20803 (thickness gauge)

: 09900–20803 (thickness gauge)

Clutch lifter pin height “a” standard: 0.2 – 0.4 Mm (0.008 – 0.016 In)

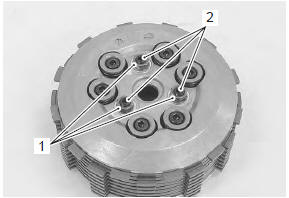

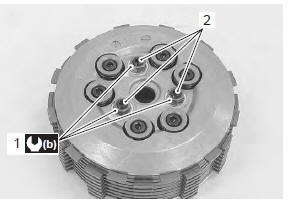

- Loosen the lock-nuts (1) and turn out the clutch lifter pin (2).

| Note each clutch lifter pin height should be as closely as possible. |

- Set the thickness gauge to 0.3 Mm (0.012 In).

Special tool

(a): 09900–20803 (thickness gauge)

(a): 09900–20803 (thickness gauge)

- Place a proper flat plate on the thickness gauges and hold them by hand.

- Slowly turn in the clutch lifter pin (2) until resistance is felt.

- Tighten the lock-nut (1).

Tightening torque clutch lifter pin lock-nut (b): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft)

Clutch parts inspection

Clutch parts inspection

Refer to “clutch removal” and “clutch installation” .

Clutch drive and driven plate

Note

wipe off the engine oil from the drive and

driven plates with a clean rag.

Measure t ...

Specifications

Specifications

Service data

Clutch

unit: mm (in)

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Clutch control system components”&nbs ...

Other materials:

Rear lighting system construction

License plate light assembly

Reflex reflector (e-03, 28, 33 only)

Clamp

: clamp the license plate light lead wire

so as not to be slack.

Rear combination light

Rear turn signal light assembly (lh/rh)

5

N·m (0.5 Kgf-m, 3.5 Lbf-ft)

1.8 N·m

...

Specifications

Service data

Wattage

unit: w

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Rear lighting system construction” “license plate light

components” “reflex reflector construction”

Reference: for the ...

Gearshift lever height inspection and

adjustment

Inspect and adjust the gearshift lever height in the

following procedures:

inspect the gearshift lever height “a” between the

lever top and footrest.

Adjust the gearshift lever height if necessary.

Gearshift lever height “a”

standard: 65 – 75 mm (2.6 – 3.0 In)

Loosen the l ...