Suzuki GSX-R 1000 Service Manual: Combination meter inspection

Led inspection

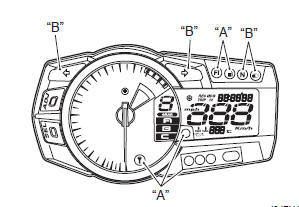

Check that the leds “a” (fi, fuel, engine rpm, oil pressure/engine coolant, immobilizer (e-02, 19, 24, 51) and meter panel illumination) immediately light up when the ignition switch is turned on.

Check that the other leds “b” (neutral, high-beam and turn signal indicator lights) light up/go off by operating each switch.

If abnormal condition is found, replace the combination meter assembly with a new one after checking its wire harness/coupler. Refer to “combination meter removal and installation” .

Stepping motor inspection and adjustment

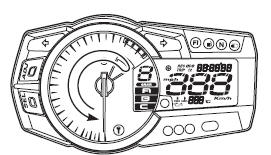

- Check that the pointers calibrate immediately after

turning the ignition switch on and stop at zero point.

If abnormal condition is found, replace the combination meter assembly with a new one after checking its wire harness/coupler.

Note

|

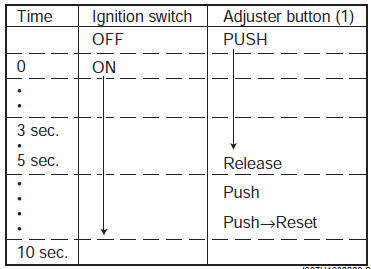

- With the adj button (1) pressed, turn the ignition switch on.

- Keep pushing the adj button for more than 3 to 5 sec.

- Release the adj button, then tap it twice.

Pointers will return to the proper position right after the completion of the operation. In the case of the pointers not returning to the proper position after doing above, replace the combination meter unit.

Refer to “combination meter removal and installation” .

Combination meter disassembly and

assembly

Combination meter disassembly and

assembly

Refer to “combination meter removal and installation” .

Disassembly disassemble the combination meter as shown in the combination meter

components. Refer to “combination meter components” .

As ...

Engine coolant temperature indicator light inspection

Engine coolant temperature indicator light inspection

Inspect the engine coolant temperature meter and indicator light (led) in the

following procedures:

remove the left side cowling. Refer to “exterior parts removal and

installation” in s ...

Other materials:

Specifications

Service data

Valve + guide

unit: mm (in)

Camshaft + cylinder head

unit: mm (in)

Cylinder + piston + piston ring

unit: mm (in)

Conrod + crankshaft

unit: mm (in)

Balancer

unit: mm (in)

Oil pump

Clutch

unit: mm (in)

Drive train

unit: mm (in) except ratio

...

Cooling circuit inspection

Do not open the radiator cap when the

engine is hot, as you may be injured by

escaping hot liquid or vapor.

When removing the radiator cap tester, put

a rag on the filler to prevent the engine

coolant from spraying out.

Inspect the cooling ...

Clutch cable removal and installation

Removal

Remove the left side cowling. Refer to “exterior parts removal and

installation” in section 9d .

Disconnect the clutch cable from the clutch lever.

Refer to “handlebar removal and installation” in section 6b .

Remove the clutch cable as shown in the throttle cable ro ...