Suzuki GSX-R 1000 Service Manual: Drive chain replacement

Use the special tool in the following procedures, to cut and rejoin the drive chain.

| Note when using the special tool, apply a small quantity of grease to the threaded parts of the special tool. |

Special tool

: 09922–22711 (drive chain cutting

: 09922–22711 (drive chain cutting

and joint

tool set)

Drive chain cutting

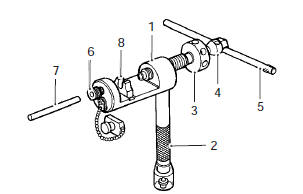

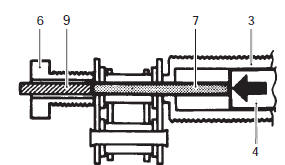

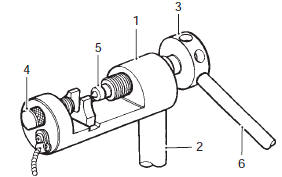

- Set up the special tool as shown in the figure.

|

| Note the tip of pin remover (7) should be positioned inside “a” approximately 5 mm (0.2 In) from the end face of pressure bolt [a] (3) as shown in the figure. |

|

- Place the drive chain link being disjointed on the chain holder (8) of the tool.

- Turn in both the adjuster bolt (6) and pressure bolt [a] (3) so that each of their end hole fits over the chain joint pin properly.

- Tighten the pressure bolt [a] (3) with the bar.

- Turn in the pressure bolt [b] (4) with the bar (5) and force out the drive chain joint pin (9).

| Caution continue turning in the pressure bolt [b] (4) until the joint pin should been completely pushed out of the chain. |

| Note after the joint pin (9) is removed, loosen the pressure bolt [b] (4) and then pressure bolt [a] (3). |

- Remove the joint pin (9) of the other side of joint plate.

| Caution never reuse joint pins, o-rings and plates. |

Drive chain connecting

Do not use joint

|

Joint plate installation

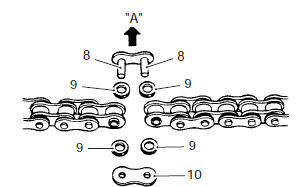

- Set up the special tool as shown in the figure.

|

- Apply grease to the joint pins (8), o-rings (9) and plates (10).

| Caution replace the joint pins (8), o-rings (9) and plates (10) with new ones. |

- Connect both ends of the drive chain with the joint pins (8) inserted from the wheel side “a” as installed on the motorcycle.

Joint set part number did: 27620 – 40f20

- Apply grease on the recessed portion of the joint plate holder (3) and set the joint plate (10).

| Note when positioning the joint plate (10) on the tool, its stamp mark must face the joint plate holder (3) side. |

- Set the drive chain on the tool as illustrated and turn in the adjuster bolt (5) to secure the wedge holder and wedge pin (4).

- Turn in the pressure bolt [a] (6) and align two joint pins (8) properly with the respective holes of the joint plate (10).

- Turn in the pressure bolt [a] (6) further using the bar (7) to press the joint plate over the joint pins.

- Continue pressing the joint plate until the distance between the two joint plates comes to the specification.

Joint plate distance specification “a” 20.7 – 21.0 Mm (0.81 – 0.83 In)

| Caution if pressing of the joint plate makes the dimension out of specification excessively, the work must be carried out again by using new joint parts. |

Joint pin staking

- Set up the special tool as shown in the figure.

|

| Note before staking the joint pin, apply a small quantity of grease to the staking pin (5). |

- Stake the joint pin by turning (approximately 7/8 turn) the pressure bolt [a] (3) with the bar until the pin end diameter becomes the specified dimension.

Caution

|

Pin end diameter specification “a” did: 5.7 – 6.0 Mm (0.22 – 0.24 In)

- Adjust the drive chain slack, after connecting it.

Refer to “drive chain inspection and adjustment” in section 0b .

Sprocket mounting drum dust seal / bearing removal and installation

Sprocket mounting drum dust seal / bearing removal and installation

Removal

Remove the rear wheel assembly. Refer to “rear wheel assembly removal

and installation” in section 2d .

Remove the rear sprocket mounting drum assembly

(1). Refer to “rear spr ...

Specifications

Specifications

Service data

Drive train

unit: mm (in) except ratio

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Drive chain related ...

Other materials:

Side-stand removal and installation

Removal

Support the motorcycle with a jack or wooden block.

Caution

do not support the motorcycle with the exhaust pipes.

Make sure that the motorcycle is supported securely.

Remove the side-stand as shown in the side-stand construction.

Refer to ...

Rear brake master cylinder components

Reservoir cap

Plate

Diaphragm

Reservoir tank

Reservoir hose

Brake hose

Brake hose union bolt

Brake hose connector

Master cylinder

Spring

Piston/cup set

Push rod

Dust boot

23 N·m (2.3 Kgf-m,

16.5 Lbf-ft)

10 N·m

...

Gearshift lever height inspection and

adjustment

Inspect and adjust the gearshift lever height in the

following procedures:

inspect the gearshift lever height “a” between the

lever top and footrest.

Adjust the gearshift lever height if necessary.

Gearshift lever height “a”

standard: 65 – 75 mm (2.6 – 3.0 In)

Loosen the l ...