Suzuki GSX-R 1000 Service Manual: DTC “c15” (p0115-h/l): ect sensor circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

||

| C15 | Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < 4.85 V |

|

|

| P0115 | H | Sensor voltage is higher than specified value. | |

| L | Sensor voltage is lower than specified value. | ||

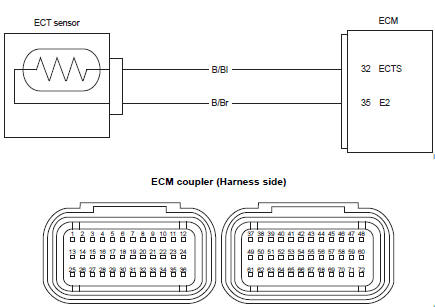

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

C15 (use of mode select switch)

|

Step |

Action |

Yes |

No |

|

1 |

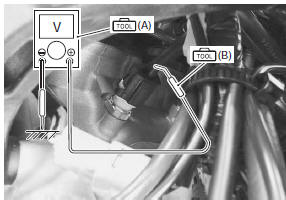

Special tool Tester knob indication

voltage ( Ect sensor input voltage 4.5 – 5.5 V ((+) terminal: b/bl – (–) terminal: ground, (+) terminal: b/bl – (–) terminal: b/br)

Is the voltage ok? |

Go to step 2. |

|

P0115-h (use of sds)

|

Step |

Action |

Yes |

No |

|

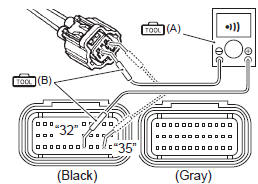

1 |

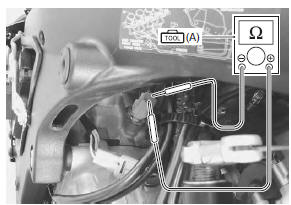

Special tool Tester knob indication

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | B/bl or b/br wire open. |

P0115-l (use of sds)

|

Step |

Action |

Yes |

No |

|

|

1 |

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

voltage ( Ect sensor output voltage 0.15 – 4.85 V ((+) terminal: b/bl – (–) terminal: ground)

Are the continuity and voltage ok? |

Go to step 2. |

|

|

|

2 |

Special tool Tester knob indication resistance (Ω) Ect sensor resistance approx. 2.45 KΩ at 20 °c (68 °f) (terminal – terminal)

Is the resistance ok? |

|

Replace the ect

sensor with a new one. Refer to “ect sensor removal and installation” in section 1c . |

DTC “c14” (p0120-h/l): tp sensor circuit

malfunction

DTC “c14” (p0120-h/l): tp sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C14

Output voltage is not within the following

range.

Difference between actual throttle op ...

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C21

Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < ...

Other materials:

DTC “c40” (p0505 / p0506 / p0507): isc

valve circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

C40/P0505

The circuit voltage of motor drive is

unusual.

Isc valve circuit open or shorted to ground.

Air passage clogged.

Isc valve is fixed.

Isc valve prese ...

Tp sensor adjustment

Inspect the tp sensor setting position and adjust it if

necessary in the following procedures:

connect the special tool (mode select switch) to the dealer mode

coupler. Refer to “self-diagnostic procedures” in section 1a .

Special tool

: 09930–82720 (mode selection switch)

Warn ...

Front brake hose routing diagram

Hose clamp

: clamp end should face downward.

Stopper

: after the brake hose union has contacted to the stopper, tighten

the union bolt.

Hose guide

: pass the brake hose through the hose guide.

Stopper

: after positioning the clamp with the stopper ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)