Suzuki GSX-R 1000 Service Manual: DTC “c14” (p0120-h/l): tp sensor circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

||

| C14 | Output voltage is not within the following

range. Difference between actual throttle opening and opening calculated by ecm is larger than specified value. 0.2 V ≤ Sensor voltage < 4.8 V |

|

|

| P0120 | H | Sensor voltage is higher than specified value. |

|

| L | Sensor voltage is lower than specified value. | ||

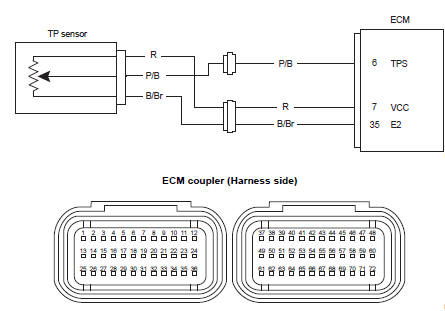

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

C14 (use of mode select switch)

|

Step |

Action |

Yes |

No |

| 1 |

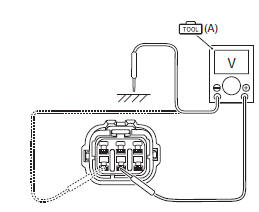

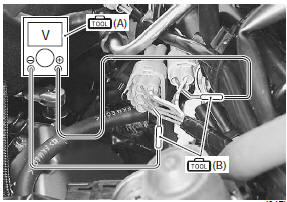

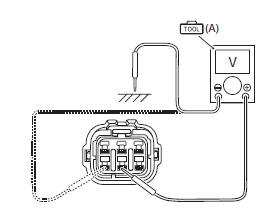

Special tool

Tester knob indication

voltage ( Tp sensor input voltage 4.5 – 5.5 V ((+) terminal: r – (–) terminal: ground, (+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. |

|

P0120-h (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

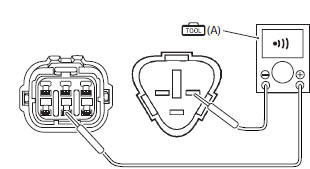

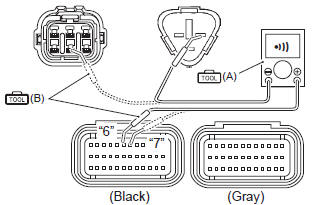

Special tool Tester knob indication

continuity (

Special tool Tester knob indication continuity test ( ) Ecm couplers (harness side)

Is the continuity ok? |

Go to step 3. | P/b wire shorted to vcc, or b/br wire open |

P0120-l (use of sds)

|

Step |

Action |

Yes |

No |

|

1 |

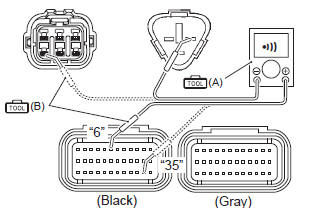

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | R or p/b wire open, or y/w wire shorted to ground. |

|

2 |

Special tool Tester knob indication

voltage ( Tp sensor input voltage 4.5 – 5.5 V ((+) terminal: r – (–) terminal: ground, (+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. | Open or short circuit in the r or b/br wire. |

|

3 |

Special tool Tester knob indication

voltage ( Tp sensor output voltage throttle valve is closed: approx. 1.1 V throttle valve is opened: approx. 4.4 V ((+) terminal: p/b – (–) terminal: b/br)

Is the voltage ok? |

|

If check result is not

satisfactory, replace tp

sensor with a new one. Refer to “throttle body disassembly and assembly” in section 1d . |

DTC “c13” (p0105-h/l): iap sensor circuit

malfunction

DTC “c13” (p0105-h/l): iap sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C13

Iap sensor voltage is not within the

following range.

0.5 V ≤ Sensor voltage &l ...

DTC “c15” (p0115-h/l): ect sensor circuit

malfunction

DTC “c15” (p0115-h/l): ect sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C15

Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < ...

Other materials:

Oil jet removal and installation

Piston cooling oil jet

Removal

Remove the engine assembly. Refer to “engine assembly removal” in

section 1d .

Remove the crankshaft assembly. Refer to “engine

bottom side disassembly” in section 1d (page 1d-

49).

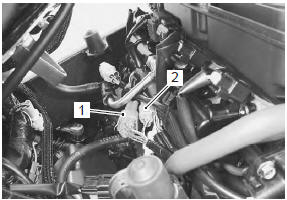

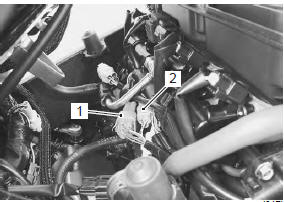

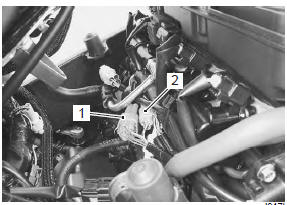

Remove the piston cooling oil jets (1) from the upper

cra ...

Starter torque limiter inspection

Removal

Remove the clutch cover. Refer to “clutch removal” in section 5c .

Remove the washers (1), starter idle gear no. 1 (2)

And no. 2 (3).

Remove the starter idle gear no. 2 Bearing (4), shaft

(5) and washer (6).

Hold the starter clutch with the special tool an ...

Turn signal / side-stand relay removal and installation

Removal

Remove the frame cover. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Remove the turn signal/side-stand relay (1).

Installation

Install the turn signal/side-stand relay in the reverse

order of removal. ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)

)

)