Suzuki GSX-R 1000 Service Manual: DTC “c28” (p1655): secondary throttle valve actuator (stva) malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

| The operation voltage does not reach the stva. Ecm does not receive communication signal from the stva. Stva can not operate properly or its motor locked |

|

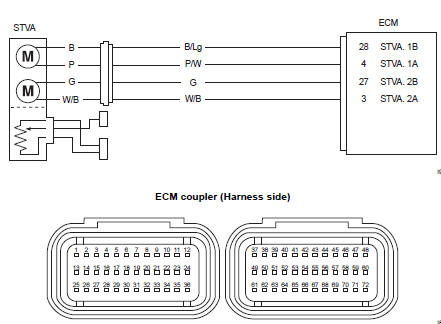

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

1 |

Is the operation ok? |

Go to step 2. |

|

| 2 |

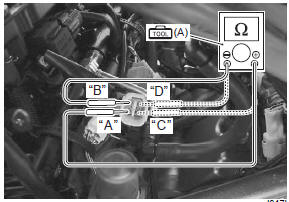

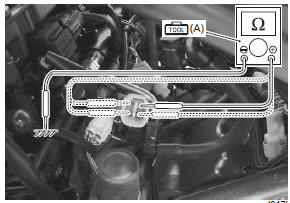

Special tool (a): 09900–25008 (multi circuit tester set) Tester knob indication resistance (Ω) Stva continuity ∞Ω¶ (infinity) (terminal . Ground)

Special tool

Stva resistance approx. 6.5 Ω (terminal “a” – terminal “b”, terminal “c” – terminal “d”)

|

|

|

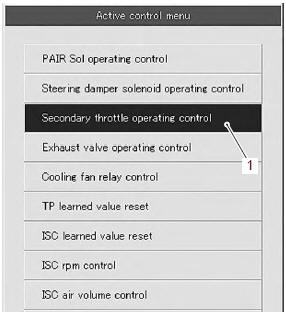

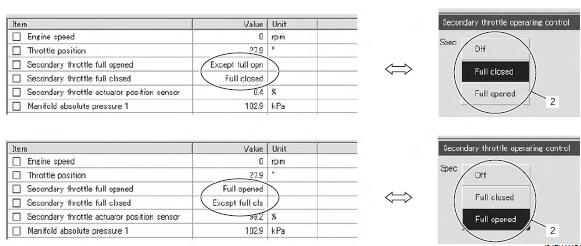

Active control inspection

- Set up the sds tool. (Refer to the sds operation manual for further details.)

- Turn the ignition switch on.

- Click “secondary throttle operating control” (1).

- Click each button (2).

At this time, if an operation sound is heard from the stva, the function is normal.

DTC “c23” (p1651-h/l): to sensor circuit

malfunction

DTC “c23” (p1651-h/l): to sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C23

The sensor voltage should be the

following for 2 sec. And more, after ignition

switch i ...

DTC “c29” (p1654-h/l): secondary throttle

position sensor (stps) circuit malfunction

DTC “c29” (p1654-h/l): secondary throttle

position sensor (stps) circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

C29

Output voltage is not within the following

range.

Difference between actual throttle op ...

Other materials:

Precautions

Precautions for brake system

Refer to “general precautions” in section 00 (page 00-1).

Brake fluid information

This brake system is filled with an ethylene glycol-based dot 4

brake fluid. Do not use or mix

different types of fluid, such as silicone-based or petroleum-based.

...

Ecm / various sensors

Since each component is a high-precision part, great

care should be taken not to apply any severe impacts

during removal and installation.

Be careful not to touch the electrical terminals of the

electronic parts (ecm, etc.). The static electricity from

your body may damage them. ...

Chassis bolt and nut inspection

Tighten chassis bolt and nut

initially at 1 000 km (600 miles, 2 months) and every

6 000 km (4 000 miles, 12 months) thereafter

Check that all chassis bolts and nuts are tightened to

their specified torque.

Steering stem

lock-nut 80 n·m (8.0 Kgf-m, 58.0 Lbf-ft)

Stee ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi