Suzuki GSX-R 1000 Service Manual: DTC “c29” (p1654-h/l): secondary throttle position sensor (stps) circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

||

| C29 | Output voltage is not within the following

range. Difference between actual throttle opening and opening calculated by ecm is larger than specified value. 0.15 V ≤ Sensor voltage < 4.85 V |

|

|

| P1654 | H | Sensor voltage is higher than specified value. | |

| L | Sensor voltage is lower than specified value. | ||

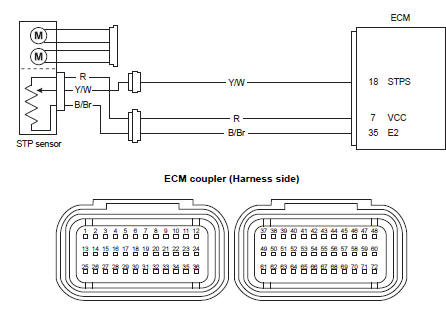

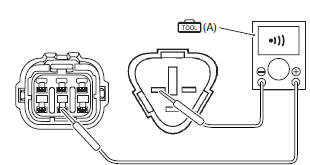

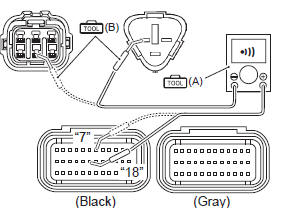

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

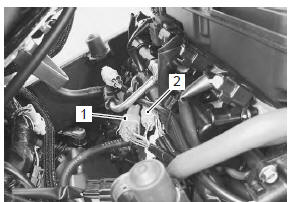

C29 (use of mode select switch)

|

Step |

Action |

Yes |

No |

|

1 |

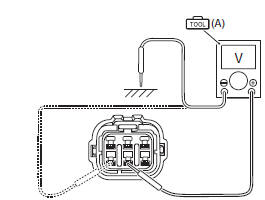

Special tool Tester knob indication

voltage ( Stp sensor input voltage 4.5 – 5.5 V ((+) terminal: r – (–) terminal: ground, (+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. |

|

P1654-h (use of sds)

|

Step |

Action |

Yes |

No |

|

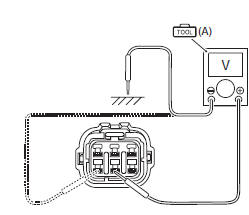

1 |

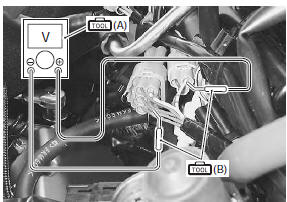

Special tool Tester knob indication

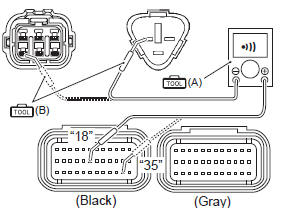

continuity (

Special tool

(a):

(b):

Tester knob indication

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 3. | Y/w wire shorted to vcc, or b/br wire open. |

P1654-l (use of sds)

|

Step |

Action |

Yes |

No |

|

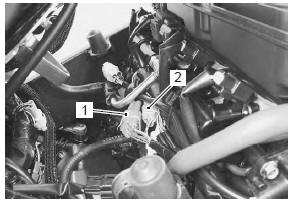

1 |

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

continuity test ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | R or y/w wire open, or y/w wire shorted to ground. |

|

2 |

Special tool

Tester knob indication

voltage ( Stp sensor input voltage 4.5 – 5.5 V ((+) terminal: r – (–) terminal: ground, (+) terminal: r – (–) terminal: b/br)

Is the voltage ok? |

Go to step 3. | Open or short circuit in the r or b/br wire. |

|

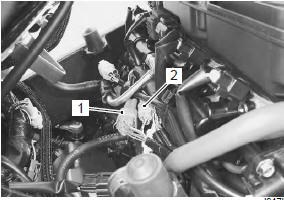

3 |

Special tool Tester knob indication

voltage ( Stp sensor output voltage secondary throttle valve is closed: approx. 0.7 V secondary throttle valve is opened: approx. 4.1 V ((+) terminal: y/w – (–) terminal: b/br)

Is the voltage ok? |

|

If check result is not satisfactory, replace the stp sensor with a new one. Refer to “stp sensor removal and installation” in section 1c . |

DTC “c28” (p1655): secondary throttle

valve actuator (stva) malfunction

DTC “c28” (p1655): secondary throttle

valve actuator (stva) malfunction

Detected condition and possible cause

Detected condition

Possible cause

The operation voltage does not reach the stva.

Ecm does not receive communication signal from the ...

DTC “c31” (p0705): gp switch circuit

malfunction

DTC “c31” (p0705): gp switch circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

No gear position switch voltage

Gp switch voltage is not within the following range.

Gp switch ...

Other materials:

Foreword

Motorcycling is one of the most

exhilarating sports and to ensure

your riding enjoyment, you should

become thoroughly familiar with

the information presented in this

owner's manual before riding the

motorcycle.

The proper care and maintenance

that your motorcycle requires is

outlined in t ...

Headlight

To replace the headlight bulbs,

perform the following steps:

Upper light bulb

Remove the bolt 1 to lift the

instrument panel 2.

Turn the cap 3 counterclockwise

and remove it.

Unhook the bulb holder spring

4 and pull out the socket 5.

Pull off the bulb from ...

Precautions

Keep away from fire or spark.

During disassembling, use care to minimize spillage of

gasoline.

Spilled gasoline should be wiped off immediately.

Work in a well-ventilated area.

For e-33 models, drain fuel from the fuel tank before

...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)