Suzuki GSX-R 1000 Service Manual: DTC “c23” (p1651-h/l): to sensor circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

||

| C23 | The sensor voltage should be the

following for 2 sec. And more, after ignition

switch is turned on.

0.2 V ≤ Sensor voltage < 4.8 V |

|

|

| P1651 | H | Sensor voltage is higher than specified value. | |

| L | Sensor voltage is lower than specified value. | ||

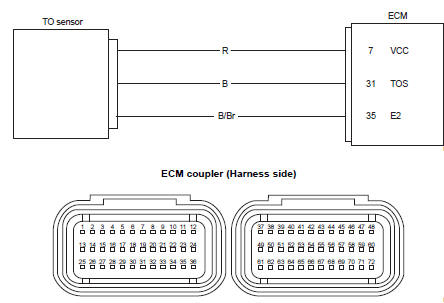

Wiring diagram

Troubleshooting

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

C23 (use of mode select switch)

|

Step |

Action |

Yes |

No |

|

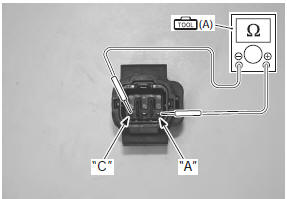

1 |

Special tool Tester knob indication resistance (Ω) To sensor resistance 16.5 – 22.3 KΩ (terminal “a” – terminal “c”)

Is the resistance ok? |

Go to step 2. | Replace the to sensor with a new one. Refer to “to sensor removal and installation” in section 1c (page 1c- 6). |

P1651-h (use of sds)

|

Step |

Action |

Yes |

No |

|

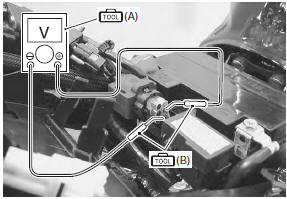

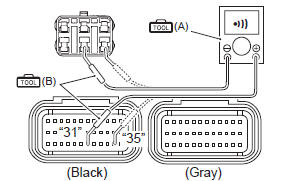

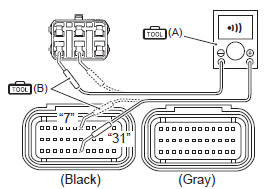

1 |

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

continuity test ( Ecm coupler (harness side)

Is the continuity ok? |

Go to step 2. | B wire shorted to vcc, or b/br wire open. |

P1651-l (use of sds)

|

Step |

Action |

Yes |

No |

|

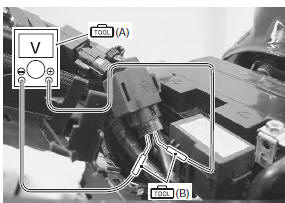

1 |

Special tool Tester knob indication continuity test (

Special tool Tester knob indication continuity test (

) Ecm coupler (harness side)

Is the continuity ok? |

Go to step 2. | R or b wire open, or b wire shorted to ground. |

|

2 |

Special tool Tester knob indication

voltage ( To sensor voltage (normal) 0.4 – 1.4 V ((+) terminal: b – (–) terminal: b/br)

Special tool To sensor voltage (leaning) 3.7 – 4.4 V ((+) terminal: b – (–) terminal: b/br)

Is the voltage ok? |

|

|

DTC “c24” (p0351), “c25” (p0352), “c26” (p0353) or “c27” (p0354): ignition system malfunction

| Note refer to “no spark or poor spark” in section 1h for details. |

DTC “c22” (p1450-h/l): ap sensor circuit

malfunction

DTC “c22” (p1450-h/l): ap sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C22

Ap sensor voltage is not within the

following range.

0.5 V ≤ Sensor voltage < ...

DTC “c28” (p1655): secondary throttle

valve actuator (stva) malfunction

DTC “c28” (p1655): secondary throttle

valve actuator (stva) malfunction

Detected condition and possible cause

Detected condition

Possible cause

The operation voltage does not reach the stva.

Ecm does not receive communication signal from the ...

Other materials:

Balancer shaft journal bearing inspection

and selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect the bearing surfaces for any signs of fusion,

pitting, burn or flaws. If any, replace them with a

specified set of bearings.

Selection

Place the plastigauge axial ...

Exhaust control system construction

Excv cable no. 1 (Cl)

Excv cable no. 2 (Op)

When

loosening or tightening the pulley bolt, be sure to fix the

pulley with an adjustable wrench, or excva may get damaged.

5 N·m (0.5 Kgf-m, 3.5 Lbf-ft)

42 – 43 Mm (1.65 – 1.69 In)

60 – 61 Mm (2.36 – ...

Front turn signal light removal and installation

Removal

Remove the screw.

Disconnect the front turn signal coupler (1).

Remove the turn signal light assembly (2).

Installation

Install the front turn signal light in the reverse order of

removal. ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

)

)

)

)