Suzuki GSX-R 1000 Service Manual: DTC “c44” (p0130/p0135): ho2 sensor (ho2s) circuit malfunction

Detected condition and possible cause

|

Detected condition |

Possible cause |

|

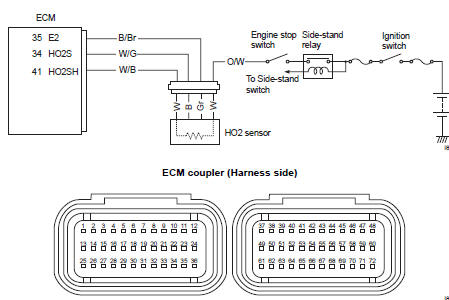

| C44/P0130 | Ho2 sensor output voltage is not input to

ecm during engine operation and running

condition. Sensor voltage > 1.0 V |

|

| C44/P0135 | The heater can not operate so that heater operation voltage is not supplied to the oxygen heater circuit. | |

Wiring diagram

Troubleshooting (when indicating c44/p0130:)

| Caution when using the multi-circuit tester, do not strongly touch the terminal of the ecm coupler with a needle pointed tester probe to prevent terminal damage. |

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

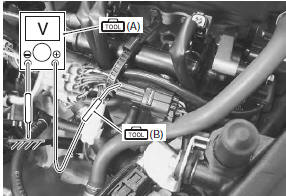

1 |

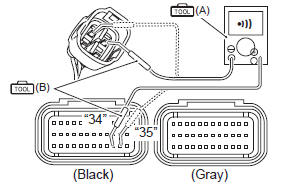

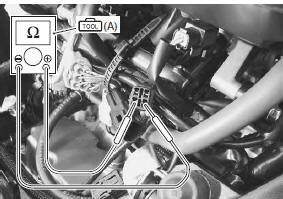

Special tool Tester knob indication

continuity test (

Special tool Tester knob indication

continuity ( Ecm couplers (harness side)

Is the continuity ok? |

Go to step 2. | W/g wire shorted to the power source, or w/g or b/br wire open. |

|

2 |

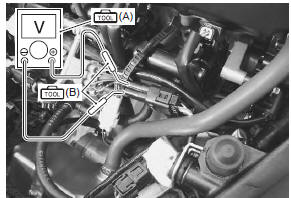

Special tool Tester knob indication

voltage ( Ho2 sensor output voltage at idle speed 0.3 V and less ((+) terminal: w/g (b) – (–) terminal: b/br (gr))

Ho2 sensor output voltage at 5 000 r/min 0.6 V and more ((+) terminal: w/g – (–) terminal: b/br) Is the voltage ok? |

|

Replace the ho2

sensor with a new one. Refer to “ho2 sensor removal and installation” in section 1c . |

Troubleshooting (when indicating c44/p0135:)

| Note after repairing the trouble, clear the dtc using sds tool. Refer to “use of sds diagnosis reset procedures” . |

|

Step |

Action |

Yes |

No |

|

|

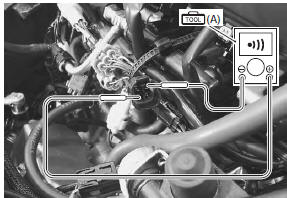

1 |

Special tool Tester knob indication resistance (Ω) Ho2 sensor heater resistance 6.7 – 9.5 Ω at 23 °c (73 °f) (w – w)

Is the resistance ok? |

Go to step 2. | Replace the ho2

sensor with a new one. Refer to “ho2 sensor removal and installation” in section 1c . |

|

|

2 |

Special tool Tester knob indication

voltage ( Heater voltage battery voltage ((+) terminal: w/b – (–) terminal: ground)

Is the voltage ok? |

|

|

DTC “c42” (p1650): ig switch circuit

malfunction

DTC “c42” (p1650): ig switch circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

Ignition switch signal is not input to the ecm.

Ignition system circuit open or short.

...

DTC “c46” (p1657-h/l or p1658): excv

actuator circuit malfunction

DTC “c46” (p1657-h/l or p1658): excv

actuator circuit malfunction

Detected condition

Possible cause

C46

The operation signal does not reach the

excv actuator.

Excva position sensor voltage low or

high

0.14 V ≤ Sensor v ...

Other materials:

Oil jet removal and installation

Piston cooling oil jet

Removal

Remove the engine assembly. Refer to “engine assembly removal” in

section 1d .

Remove the crankshaft assembly. Refer to “engine

bottom side disassembly” in section 1d (page 1d-

49).

Remove the piston cooling oil jets (1) from the upper

cra ...

Starter button inspection

Inspect the starter button in the following procedures:

remove the air cleaner box. Refer to “air cleaner box removal and

installation” in section 1d .

Disconnect the right handlebar switch coupler (1).

Inspect the starter button for continuity with the

tester.

If ...

Specifications

Service data

Drive train

unit: mm (in) except ratio

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Transmission components” “gearshift lever construction”

“gearshift shaft / gearshift cam plate componen ...

(a): 09900–25008 (multi

(a): 09900–25008 (multi

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

)

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(a): 09900–25008 (multi

(b): 09900–25009

(b): 09900–25009

)

)