Suzuki GSX-R 1000 Service Manual: Excva removal and installation

Removal

- Turn the ignition switch off.

- Remove the left side cowling. Refer to “exterior parts removal and installation” in section 9d .

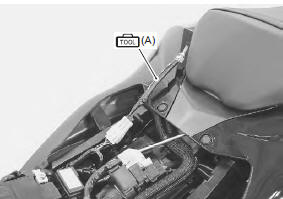

- Connect the special tool (mode select switch) to the dealer mode coupler. Refer to “self-diagnostic procedures” in section 1a .

- After turning the mode select switch on, turn the ignition switch on.

Special tool

(a): 09930–82720 (mode selection

(a): 09930–82720 (mode selection

switch)

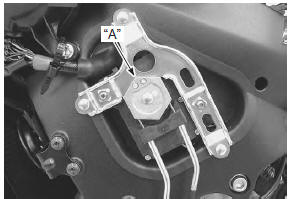

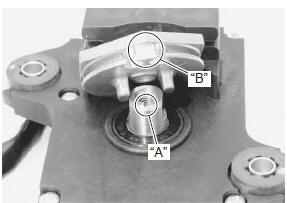

- Check that the cable slots of the excva pulley comes to the middle (adjustment position) “a”.

- Turn the ignition switch off.

| Caution before removing the excva, be sure to set the excva pulley to the adjustment position. |

- Disconnect the excva coupler (1).

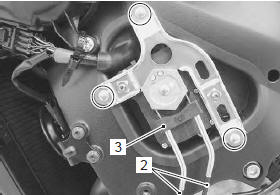

- Remove the excv cables (2). Refer to “excv cable removal and installation” .

- Remove the excva (3) with the bracket.

- Remove the bracket from the excva

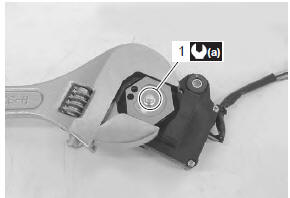

- Hold the pulley with an adjustable wrench, and loosen the pulley mounting bolt (4).

Caution

|

- Remove the pulley from the excva body.

Installation

Install the excva in the reverse order of removal. Pay attention to the following points:

- install the excva pulley to the shaft.

| Note align the shaft’s line “a” and cable slots “b”. |

- Hold the pulley with an adjustable wrench, and then tighten the pulley mounting bolt (1) to the specified torque.

Tightening torque excva pulley mounting bolt (a): 5 n·m (0.5 Kgfm, 3.5 Lbf-ft)

| Caution when loosening or tightening the pulley bolt, be sure to fix the pulley with an adjustable wrench, or excva may get damaged. |

- Install the excv cables. Refer to “excv cable removal and installation” .

- Adjust the excva. Refer to “excva adjustment” .

Excva inspection

Refer to “dtc “c46” (p1657-h/l or p1658): excv actuator circuit malfunction” in section 1a (page 1a- 109).

Excv cable removal and installation

Excv cable removal and installation

Removal

Turn the ignition switch off.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Remove the left side cowling. Refer ...

Excva pulley inspection

Excva pulley inspection

Inspect the excva pulley in the following procedures:

remove the excva pulley. Refer to “excv cable removal and installation”

.

Visually inspect the excva pulley for wear and

da ...

Other materials:

Wheel / tire / air valve inspection and cleaning

Refer to “tire removal and installation” .

Wheel

Wipe the wheel clean and check for the following points:

distortion and crack

any flaws and scratches at the bead seating area.

Wheel rim runout. Refer to “front wheel related parts inspection”

and “rear wheel rela ...

Specifications

Service data

Electrical

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Wiring harness routing diagram”

Reference: for the tightening torque of fastener not specified in this

section, refer to “tightening torque l ...

Lubrication points

Proper lubrication is important for smooth operation and long life of each

working part of the motorcycle.

Major lubrication points are indicated as follows.

Note

before lubricating each part, clean off any rusty spots

and wipe off any grease, oil, dirt or grime.

&nbs ...