Suzuki GSX-R 1000 Service Manual: Heated oxygen sensor (ho2s) removal and installation

Removal

Do not Do not

remove the ho2 sensor while it is hot. |

Caution

|

- Lift and support the fuel tank with the prop stay.

Refer to “fuel tank removal and installation” in section 1g .

- Disconnect the ho2 sensor coupler (1).

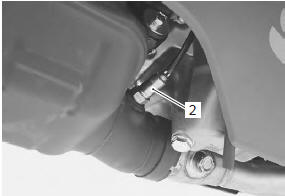

- Remove the ho2 sensor (2).

Installation

Install the ho2 sensor in the reverse order of removal.

Pay attention to the following points:

| Caution do not apply oil or other materials to the sensor air hole. |

- Tighten the ho2 sensor to the specified torque.

Tightening torque ho2 sensor (a): 25 n·m (2.5 Kgf-m, 18.0 Lbf-ft)

Heated oxygen sensor (ho2s) inspection

Refer to “dtc “c44” (p0130/p0135): ho2 sensor (ho2s) circuit malfunction” in section 1a (page 1a- 103).

Pair reed valve removal and installation

Pair reed valve removal and installation

Removal

Lift and support the fuel tank with the prop stay.

Refer to “fuel tank removal and installation” in section 1g .

Remove the air cleaner box. Refer to “air cleaner box removal and ...

Other materials:

Show data when trouble (displaying data at

the time of DTC)

Use of sds

Ecm stores the engine and driving conditions (in the form of data as shown in

the figure) at the moment of the

detection of a malfunction in its memory. This data is called “show data when

trouble”.

Therefore, it is possible to know engine and driving conditions (e.G., Whether

...

Gearshift shaft / gearshift cam plate components

Gearshift shaft

Gearshift cam drive plate

Gearshift cam plate

Gearshift cam stopper

19 N·m (1.9 Kgf-m,

13.5 Lbf-ft)

13 N·m

(1.3 Kgf-m, 9.5 Lbf-ft)

8.5 N·m

(0.85 Kgf-m, 6.0 Lbf-ft)

Apply grease to oil

seal lip.

Apply thread l ...

Fuel pump components

Fuel level gauge

Fuel pressure regulator assembly

O-ring

Joint

Fuel pump

Fuel pump case

Fuel mesh filter

10

N·m (1.0 Kgf-m, 7.0 Lbf-ft)

Apply engine oil.

Apply grease.

Do not reuse.

...