Suzuki GSX-R 1000 Service Manual: Fuel pump relay inspection

Refer to “electrical components location” in section 0a .

Inspect the fuel pump relay in the following procedures:

- remove the frame covers. Refer to “exterior parts removal and installation” in section 9d (page 9d- 6).

- Remove the fuel pump relay (1).

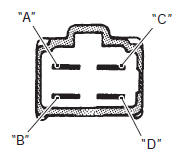

- First, check for insulation with the tester between terminals “a” and “b”. Next, check for continuity between “a” and “b” with 12 v voltage applied, positive (+) to terminal “c” and negative (–) to terminal “d”. If continuity does not exist, replace the relay with a new one.

Special tool

: 09900–25008 (multi circuit tester

: 09900–25008 (multi circuit tester

set)

Tester knob indication

continuity test (  )

)

Fuel hose inspection

Refer to “fuel line inspection” in section 0b (page 0b- 10).

Fuel level gauge inspection

Refer to “fuel level gauge inspection” in section 9c .

Fuel discharge amount inspection

Fuel discharge amount inspection

Keep away from fire or spark.

Spilled gasoline should be wiped off

immediately.

Work in a well-ventilated area.

Inspect the fuel discharge amo ...

Fuel tank construction

Fuel tank construction

Fuel tank heat

shield

: aluminum film side should face the engine side.

Fuel tank front cover

Fuel tank front bracket

Velcro fastenings

: clean the adhesiv ...

Other materials:

Side-stand / ignition interlock system parts

inspection

Check the interlock system for proper operation. If the

interlock system does not operate properly, check each

component for damage or abnormalities. If any

abnormality is found, replace the component with a new

one.

Side-stand switch

Turn the ignition switch off.

Remove the left si ...

DTC “c49” (p1656): pair control solenoid

valve circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

Pair control solenoid valve voltage is not input to ecm

Pair control solenoid valve circuit open or short.

Pair control solenoid valve malfunction.

Ecm malfunction.

...

Front brake pad inspection

The extent of brake pads wear can be checked by observing the grooved limit

line “a” on the pads. When the wear exceeds the grooved limit line, replace the

pads with new ones. Refer to “front brake pad replacement” .

Caution

replace the brake pad as a set, otherwise

braking perform ...